A high-efficiency dividing machine suitable for curtains

A splitting machine and curtain technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of manual cutting, low efficiency, wrinkling, etc., and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

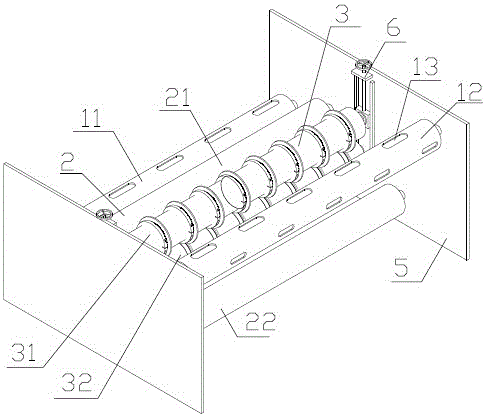

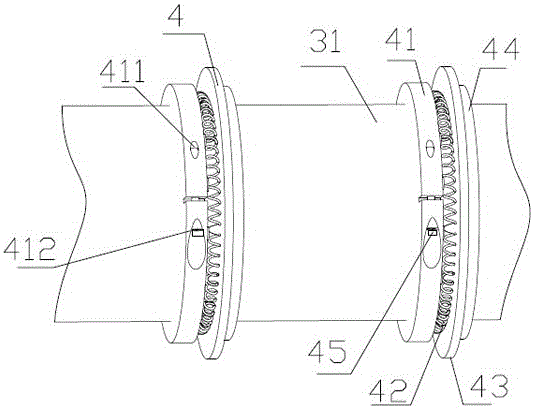

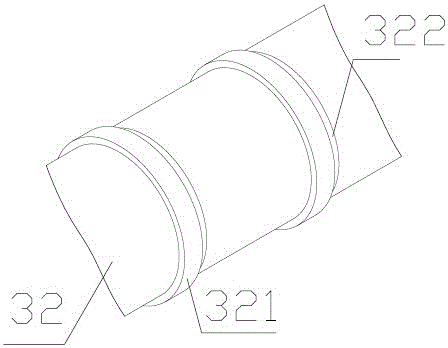

[0028] Example 1, such as figure 1 , figure 2 and image 3 Shown: a high-efficiency splitting machine suitable for curtains, including a frame 5 and a cutting device 3 installed on the frame 5. This high-efficiency splitting machine also includes an unwinding machine arranged on the frame 5 according to the forward direction of the curtain transmission. Device 11 and winding device 12, cutting device 3 is positioned between winding device 11 and winding device 12 in the horizontal direction, and cutting device 3 comprises the upper cutting device 31 that is arranged on the frame 5 according to vertical direction height and following cutting device 31. The device 32, the upper cutting device 31 includes a drum and a cutter 4 sleeved on the drum, and there are multiple cutters 4, which are evenly distributed on the upper cutting device 31. Both the unrolling device 11 and the rewinding device 12 can use rollers in the known technology. The user puts the curtain cloth on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com