Three-dimensional printer with cleanable injecting head

A spray head and printer technology, applied in the direction of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., capable of solving problems such as the impact of printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

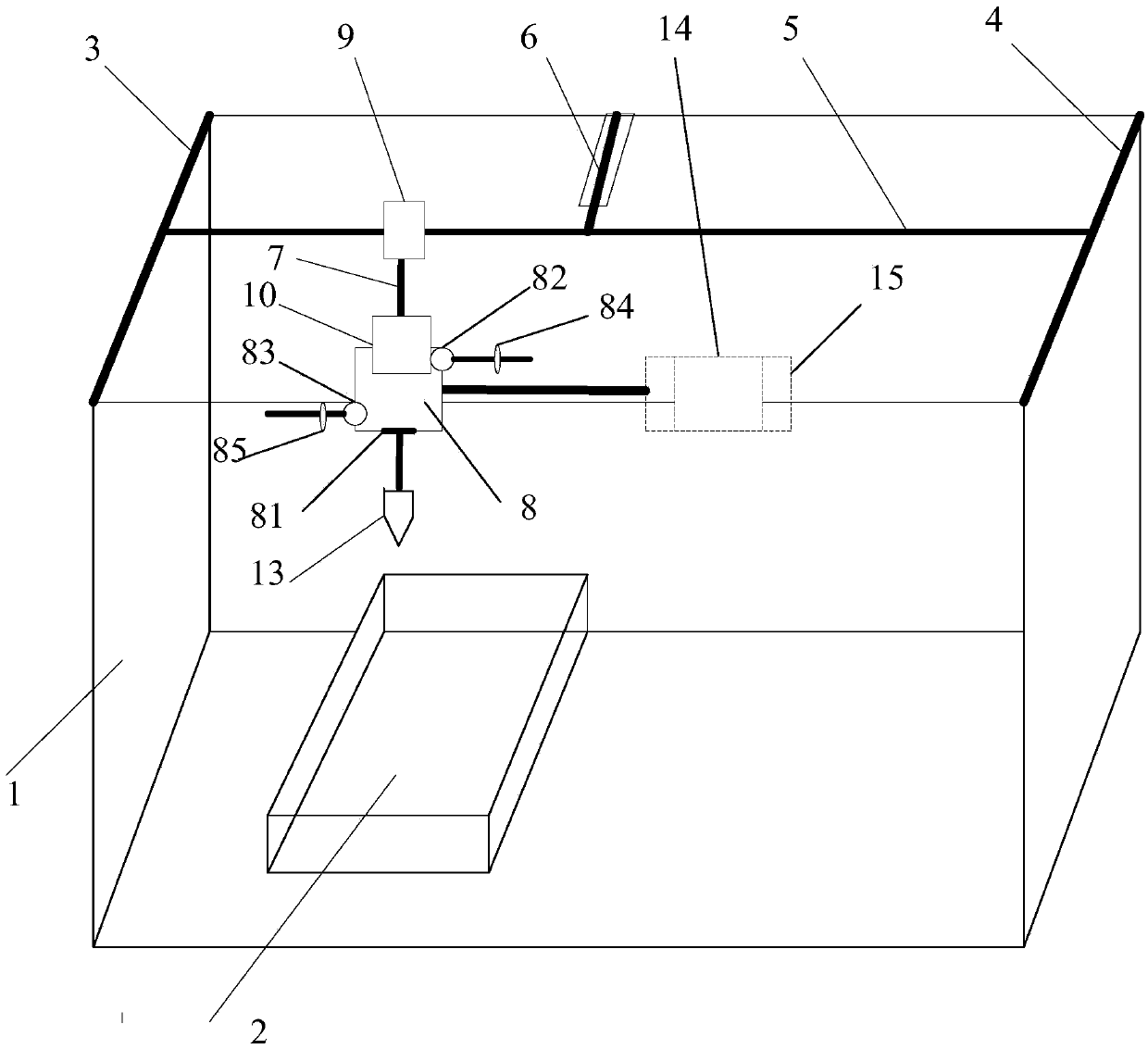

[0022] refer to figure 1 , the present invention proposes a three-dimensional printer capable of cleaning the spray head, comprising: a frame 1, a workbench 2, a first fixed rod 3, a second fixed rod 4, a sliding rod 5, a first driving mechanism 6, and a suspension rod 7 , a cleaning box 8, a second drive mechanism 9, a third drive mechanism 10, a fourth drive mechanism 11, a spray head 12, a printing material box 13, a heating device 14 and a control unit.

[0023] The workbench 2 is installed inside the frame 1 .

[0024] The first fixed rod 3 and the second fixed rod 4 are installed in parallel on the top of the frame 1 and positioned above the workbench 2, and the plane where the first fixed rod 3 and the second fixed rod 4 are located is parallel to the surface of the workbench 2; the slide bar 5 The two ends are slidably installed on the first fixed rod 3 and the second fixed rod 4 respectively, and the first driving mechanism 6 is used to drive the sliding rod 5 to sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com