Bubble scrapper for silicon

A foam board and foam pool technology, applied in the direction of foam dispersion/prevention, can solve the problems of wasting resources, cumbersome operation, and poor operating environment, and achieve the effects of easy foam scraping, improved production efficiency, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

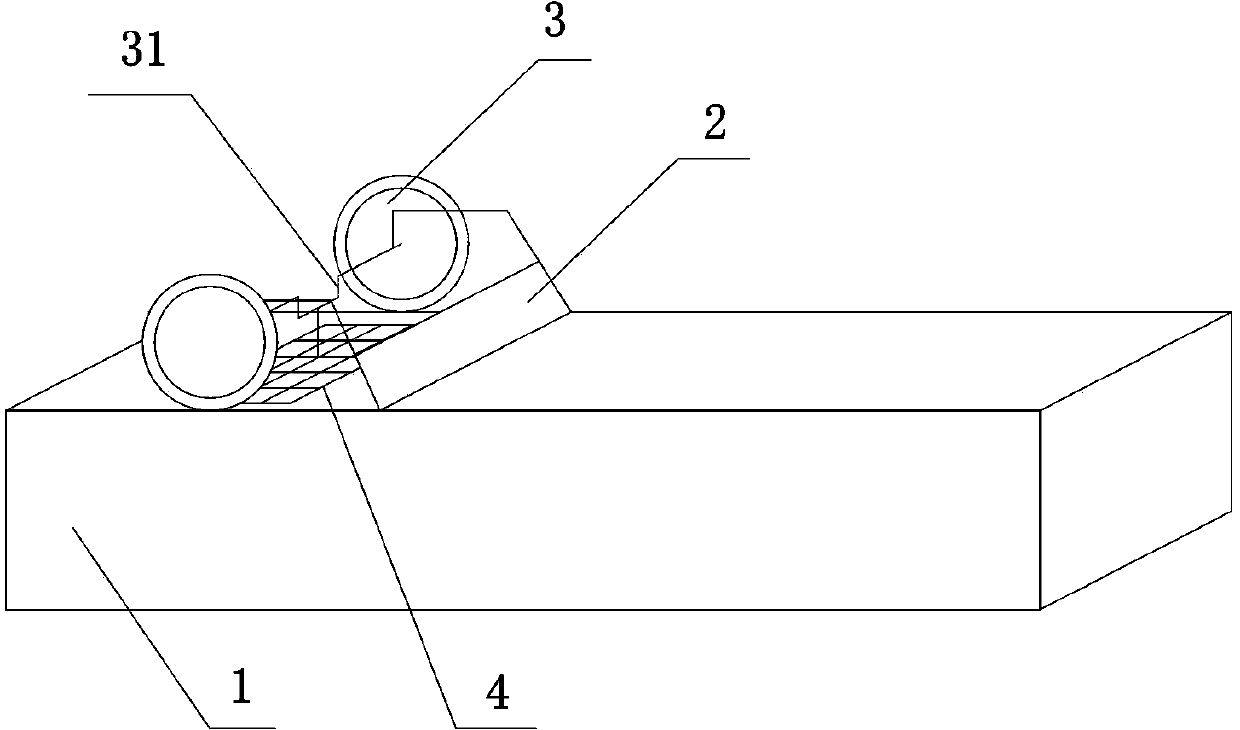

[0010] like figure 1 A silicon foam scraper shown includes a foam scraper pool 1 and a foam scraper plate 2, and the foam scraper plate 2 is set above the foam scraper pool 1 via a traveling mechanism 3; the traveling mechanism 3 is composed of a motor-driven roller ( Only draw the roller among the illustration, do not draw motor), this roller is made as crankshaft 31 structure, and the foam breaking net 4 that is hung with broken foam is hung on this crankshaft 31. The foam scraping plate 2 is arranged downstream of the crankshaft 31, so that before the foam scraping, the foam breaking net 4 breaks the foam in the foam scraping pool 1, which reduces the foam scraping strength of the foam scraping plate 2, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com