Display baseplate as well as manufacture method thereof and display device

A technology for display substrates and manufacturing methods, which is applied in the fields of instruments, nonlinear optics, optics, etc., and can solve problems such as inconsistent orientation of alignment layers, light leakage in dark states, and affecting device display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

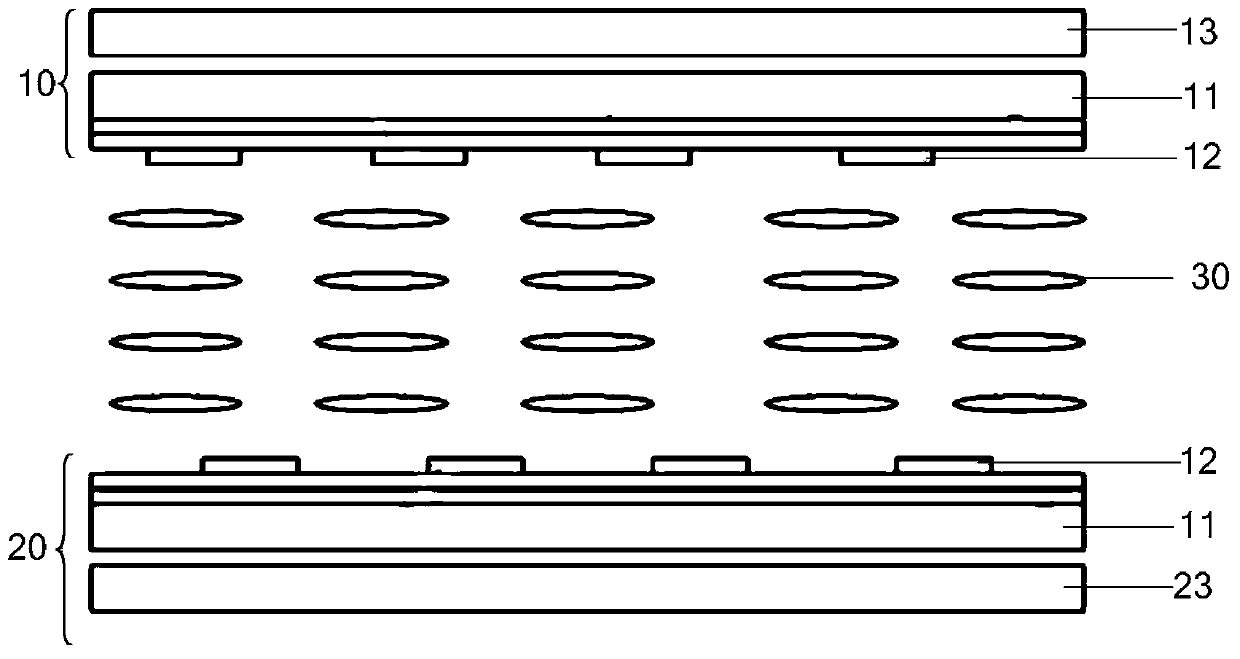

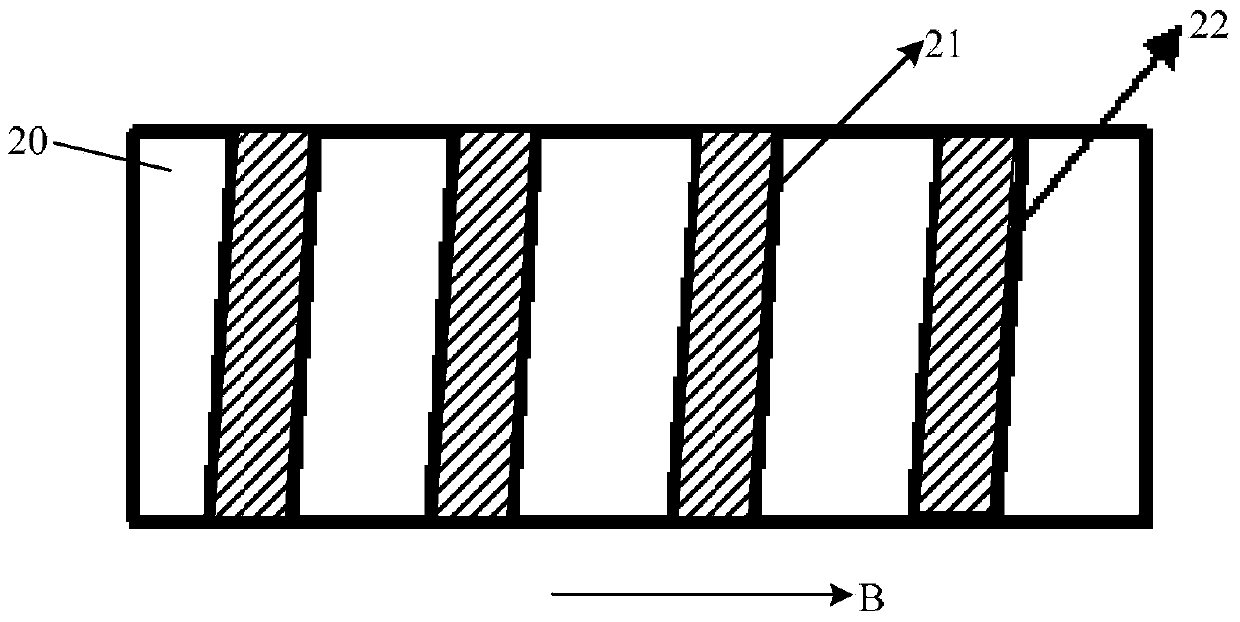

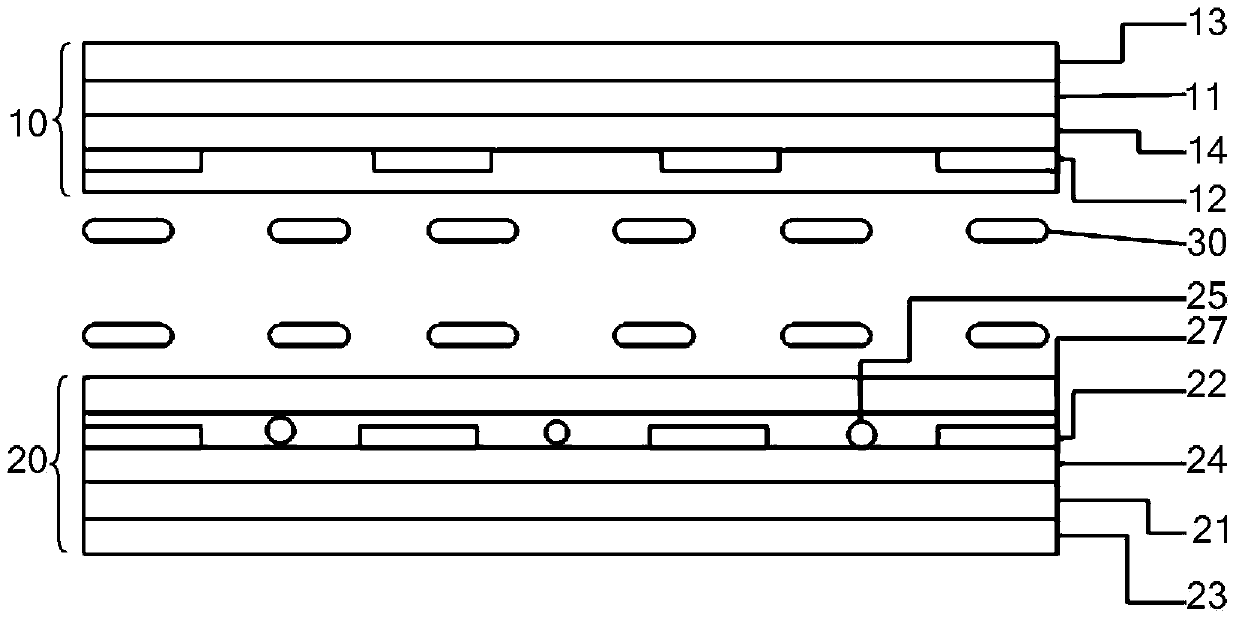

[0033] An embodiment of the present invention provides a display substrate. The display substrate is provided with: a blue-phase liquid crystal layer; and driving electrodes for driving the blue-phase liquid crystal layer in a dark state. Each group of driving electrodes includes two There are two opposite electrodes, and the components of the electric field generated by the two opposite electrodes in the blue phase liquid crystal layer in the first direction are not zero, and the first direction is perpendicular to the polarization direction of the incident light.

[0034] An embodiment of the present invention provides a display substrate, which is suitable for a flat field display device. The flat field display device mentioned here means that the electric field used to drive liquid crystal deflection for display is a parallel electric field parallel to the substrate. At present, there are mainly: plane switching technology (In-Plane Switching, referred to as IPS), Advanced ...

Embodiment 2

[0052] Embodiments of the present invention also provide a method for manufacturing a display substrate, such as Figure 5 As shown, the substrate manufacturing method also includes:

[0053] 101. The process of forming a blue phase liquid crystal layer;

[0054] 102. A process of forming driving electrodes, the driving electrodes are used to drive the blue-phase liquid crystal layer in a dark state, each group of driving electrodes includes two electrodes of the opposite sex, and the two electrodes of the opposite sex are in the blue phase The component of the electric field generated by the phase liquid crystal layer in the first direction is not zero, and the first direction is perpendicular to the polarization direction of the incident light.

[0055] The embodiment of the present invention also provides a method for manufacturing a display substrate. On the basis of the original process, the additional steps 101 and 102 of forming the blue phase liquid crystal layer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com