Site test method for feeder automation

A feeder automation and field testing technology, applied in the fault location and other directions, can solve problems such as difficult coordination, slow speed, and inability to perform batch operations, and achieve the effect of ensuring mutual consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

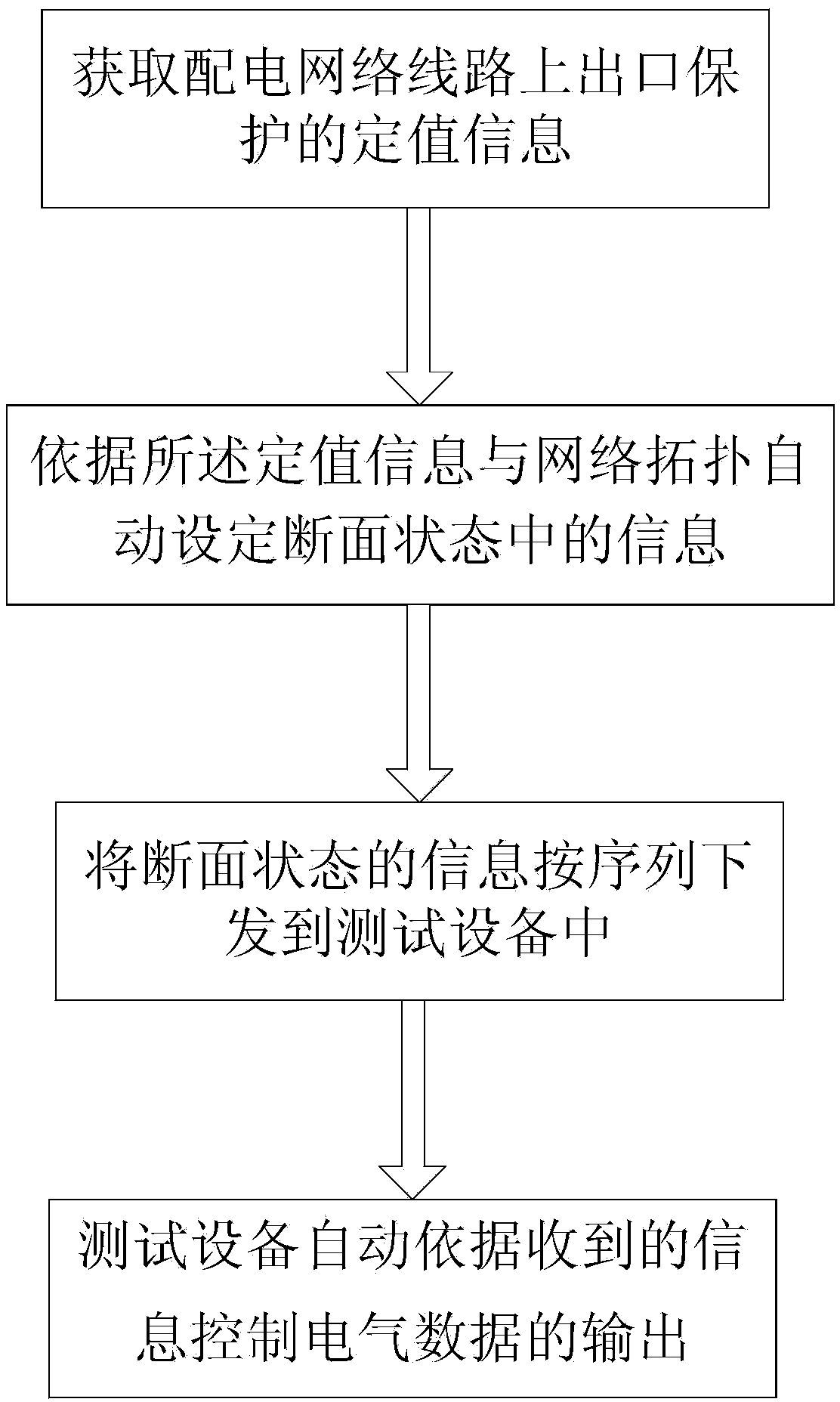

[0051] The following will combine figure 1 The field test method of feeder automation provided by the present invention is described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can modify and modify it within the scope of not changing the spirit and content of the present invention. polish.

[0052] This embodiment provides a field test method for feeder automation, including the following steps:

[0053] First obtain the fixed value information of the outlet protection on the distribution network line; wherein, the fixed value information includes whether to automatically reclose the information, the reclosing time T R , Quick-break protection operating current value V d , Quick-break protection action start time T d , Rear acceleration protection action time T j , Zero-sequence protection operating current value V 0 , Zero-sequence protection action start time T 0 And the time T that allows the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com