Cool double-effect lithium bromide absorption type refrigeration cycle system

An absorption refrigeration and circulation system technology, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problem that the outlet temperature of saturated dilute solution is low and the first cooling heat source cannot meet the application conditions of lithium bromide absorption refrigeration circulation system, etc. problems, to achieve remarkable energy-saving effects, reliable system performance, and high inlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

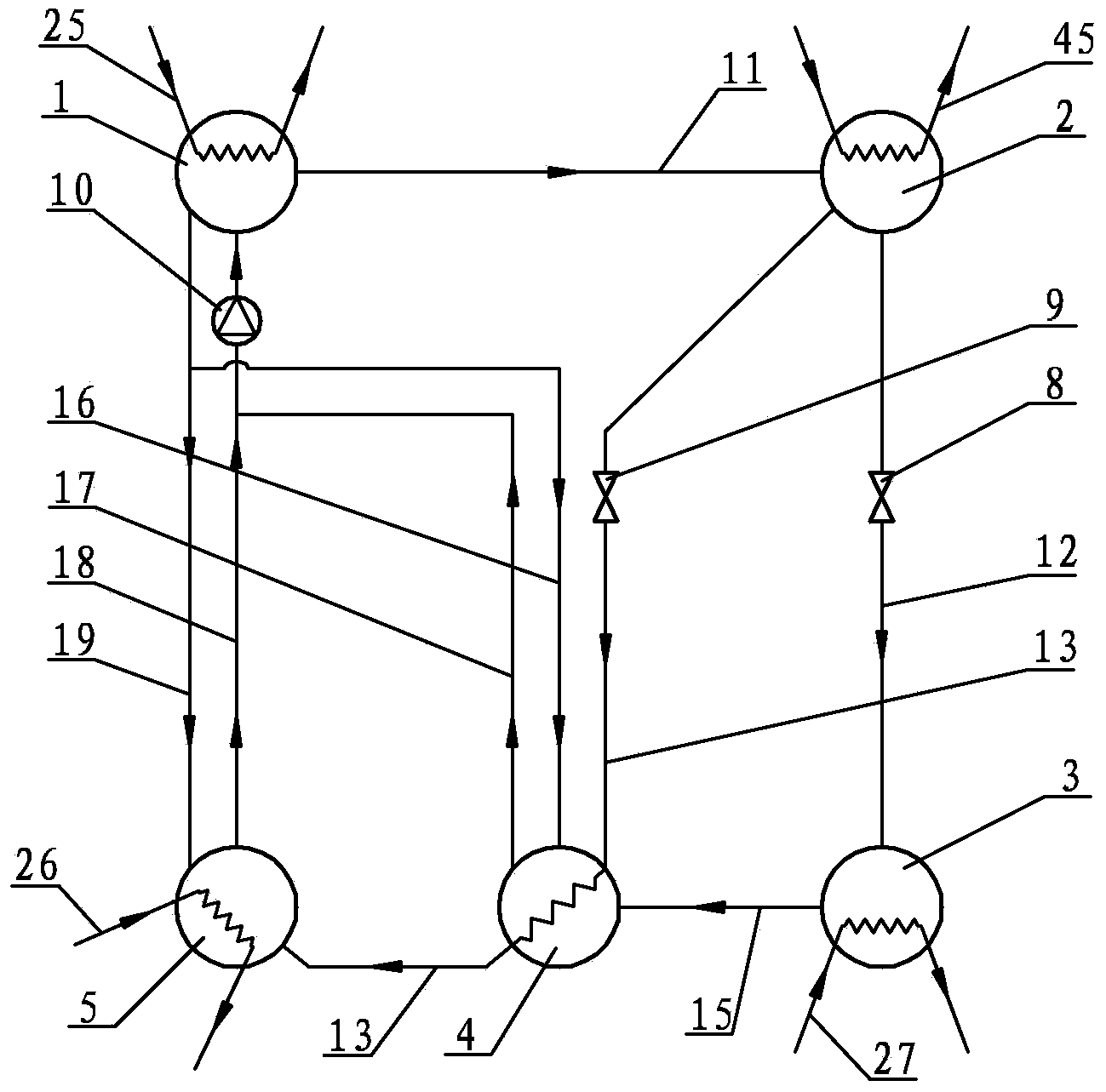

[0041] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a generator 1, a condenser 2, an evaporator 3, a first absorber 4, a second absorber 5, a first throttling expansion device 8, a second throttling expansion device 9, a first A solution pump 10, a first refrigerant water vapor pipeline 11, a first refrigerant water passage 12, a second refrigerant water passage 13, a second refrigerant water vapor pipeline 15, a second concentrated solution pipeline 16, a The second dilute solution pipeline 17, the first dilute solution pipeline 18 and the first concentrated solution pipeline 19, the generator 1 communicates with the condenser 2 through the first refrigerant water vapor pipeline 11, and the refrigerant water passage of the condenser 2 Divided into two paths, one of which: the condenser 2 communicates with the evaporator 3 through the first refrigerant water passage 12, the first throttling expansion device 8 is arrange...

specific Embodiment approach 2

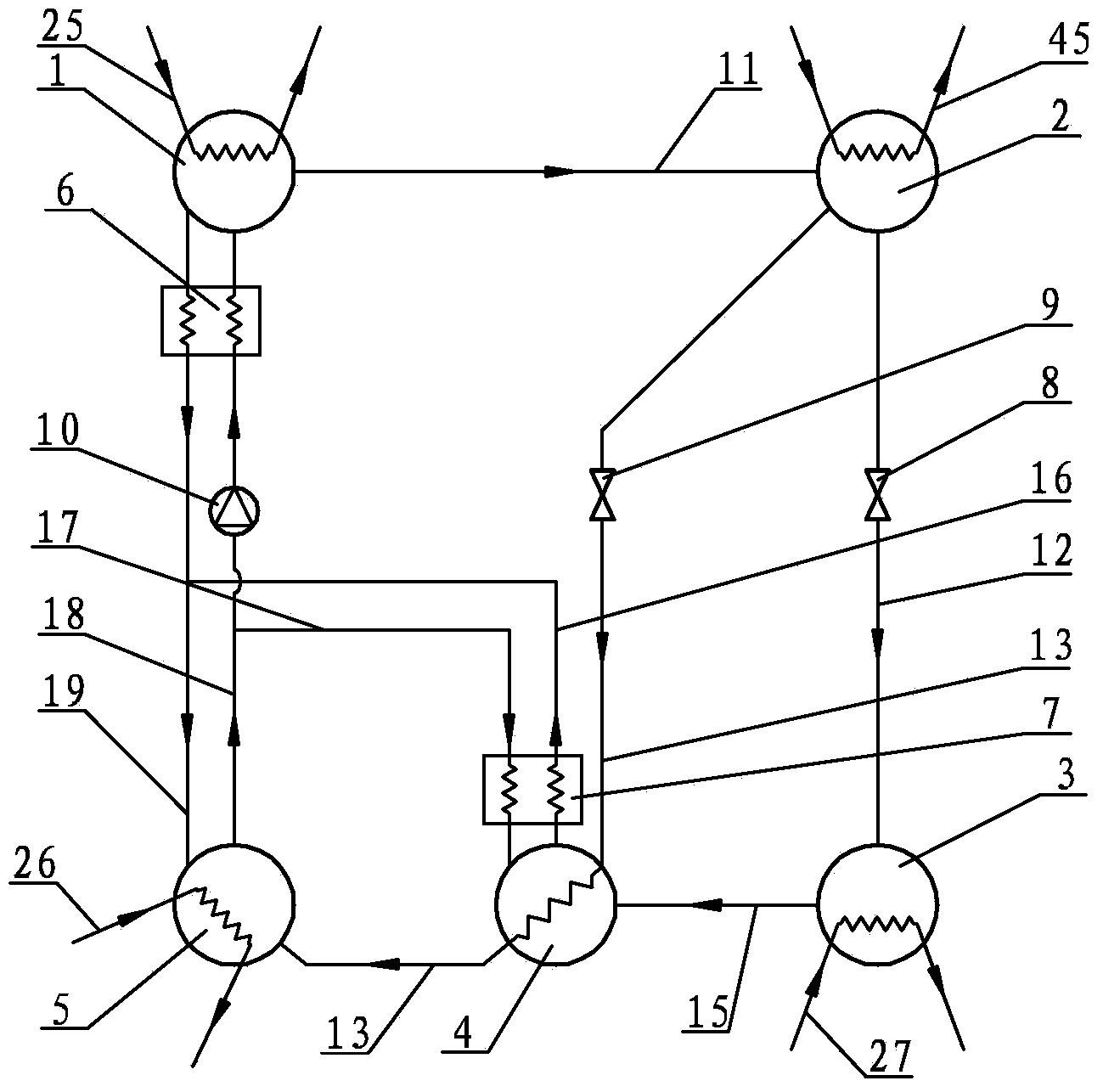

[0046] Specific implementation mode two: combination Figure 2 to Figure 5 Describe this embodiment, the difference between this embodiment and specific embodiment one is that it also adds a solution heat exchanger, and the solution heat exchanger is arranged on the first dilute solution pipeline 18 and the first concentrated solution pipeline 19 or the second On the concentrated solution pipeline 16 and the second dilute solution pipeline 17. The dilute solution flowing into the generator 1 is heat-exchanged through the solution heat exchanger, and the concentrated and dilute solutions flowing into and out of the generator 1, the second absorber 5 or the first absorber 4 are exchanged through the solution heat exchanger, This improves the efficiency of the refrigeration cycle. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0047] Specific implementation mode three: combination figure 2 Describe this embodiment, the solution heat exchanger of this embodiment adopts the first solution heat exchanger 6, the first solution heat exchanger 6 is located between the first solution pump 10 and the generator 1, and the first solution heat exchanger 6 It is arranged on the first dilute solution pipeline 18 and the first concentrated solution pipeline 19 . The dilute solution flowing into the generator 1 is heat-exchanged in the first solution heat exchanger 6, and through the first solution heat exchanger 6, the concentrated and dilute solutions flowing into and out of the generator 1 are exchanged heat, thereby improving the refrigeration cycle s efficiency. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com