A papermaking method for inhibiting plant fiber decay

A plant fiber and fiber decay technology, applied in the field of papermaking, to achieve the effects of good environmental friendliness, simple production process and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

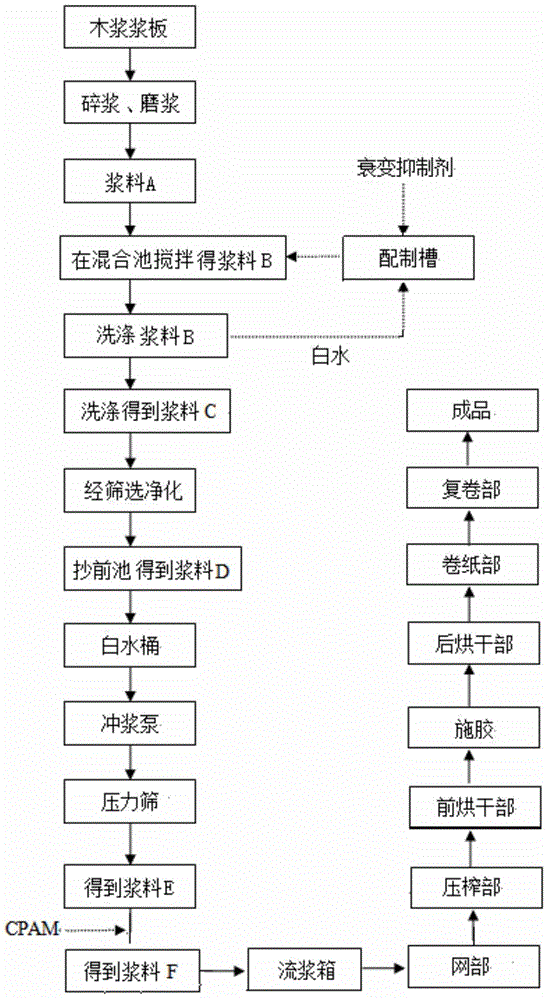

[0034] Embodiment 1: the present invention provides a kind of papermaking method that suppresses plant fiber decay, as figure 1 shown. Papermaking method of the present invention is specifically operated as follows:

[0035] Step (1), first pulping and refining the wood pulp board to obtain slurry A; the concentration of slurry A is 3.5%, and the wood pulp board adopts bleached chemical wood pulp, wherein the percentage by mass is coniferous wood 50, Hardwood 50.

[0036] Step ⑵, prepare the fiber decay inhibitor suspension in the preparation tank; the fiber decay inhibitor component is Al(OH) 3 and Mg(OH) 2 , by mass percentage, the Al(OH) 3 40, Mg(OH) 2 60, added to water to prepare a suspension with a concentration of 6%.

[0037] Step ⑶, mix and stir the slurry A obtained in step ⑴ after refining treatment and the fiber decay inhibitor suspension prepared in step ⑵ in the mixing tank, and the two materials are: slurry A98, decay inhibitor 2. Mix and stir the above t...

Embodiment 2

[0046] Embodiment 2: the present invention provides a kind of papermaking method that suppresses plant fiber decay, and its operation step is with embodiment 1: different is:

[0047]Step (1) medium wood pulp: adopt bleached chemical wood pulp, wherein coniferous wood: hardwood=60:40. The concentration of slurry A obtained after the pulp board is refined is 3.8%.

[0048] Fiber Decay Inhibitor: Al(OH) 3 :Mg(OH) 2 , the ratio of the two is 60:40, and it is added into water to form a suspension with a concentration of 8%.

[0049] The ratio of stock A and fiber decay inhibitor is 96:4.

[0050] The mixing and stirring speed is 2800r / min, and the stirring time is 40min.

[0051] The slurry C concentration after washing is 0.95%.

[0052] The added amount of CPAM is 0.25% of the absolute dry pulp mass.

[0053] The slurry F concentration was 0.6%.

[0054] In the sizing process, the sizing agent used is surface sizing starch, and the dosage is 2.6g / m 2 .

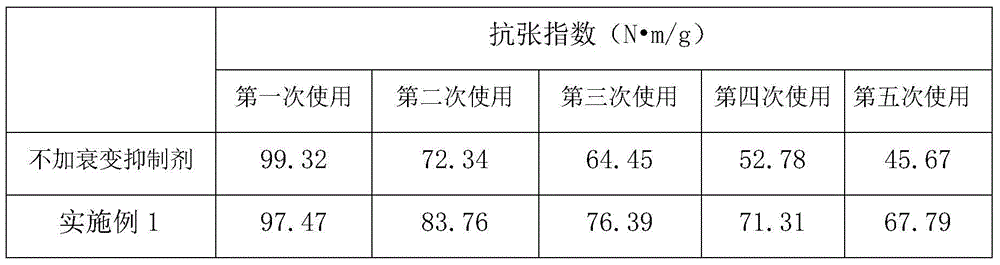

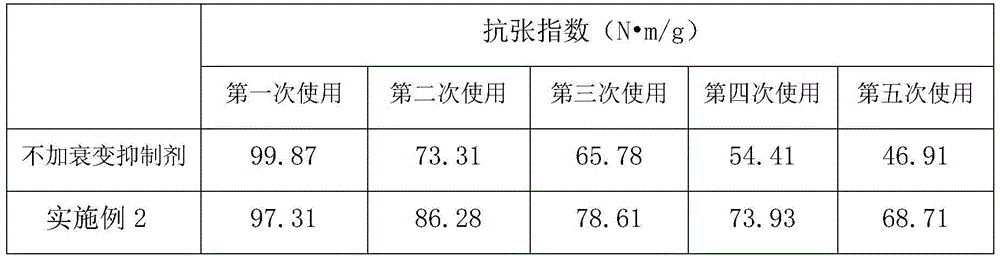

[0055] The stre...

Embodiment 3

[0058] Embodiment 3: the present invention provides a kind of papermaking method that suppresses plant fiber decay, and its operating steps are the same as embodiment 1: difference is: step (1) middle wood pulp: adopt bleached chemical wood pulp, coniferous wood: hardwood=37:63 . The concentration of the slurry A obtained after the pulp board is refined is 3.0%.

[0059] Fiber Decay Inhibitor: Only Al(OH) is used 3 , without Mg(OH) 2 , added to water to form a suspension with a concentration of 10%.

[0060] The ratio of pulp A and fiber decay inhibitor is 95:5.

[0061] The mixing and stirring speed is 3000r / min, and the stirring time is 45min.

[0062] The slurry C concentration after washing was 1.0%.

[0063] The added amount of CPAM is 0.4% of the absolute dry pulp mass.

[0064] The slurry F concentration was 0.8%.

[0065] In the sizing process, the sizing agent used is surface sizing starch, and the dosage is 3g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com