a refueling mechanism

A technology of refueling mechanism and adjusting mechanism, which is applied in special dispensing devices, packaging, dispensing devices, etc. It can solve problems such as insufficient control of refueling volume, inaccurate refueling position, and low safety factor, so as to improve efficiency and control refueling volume , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

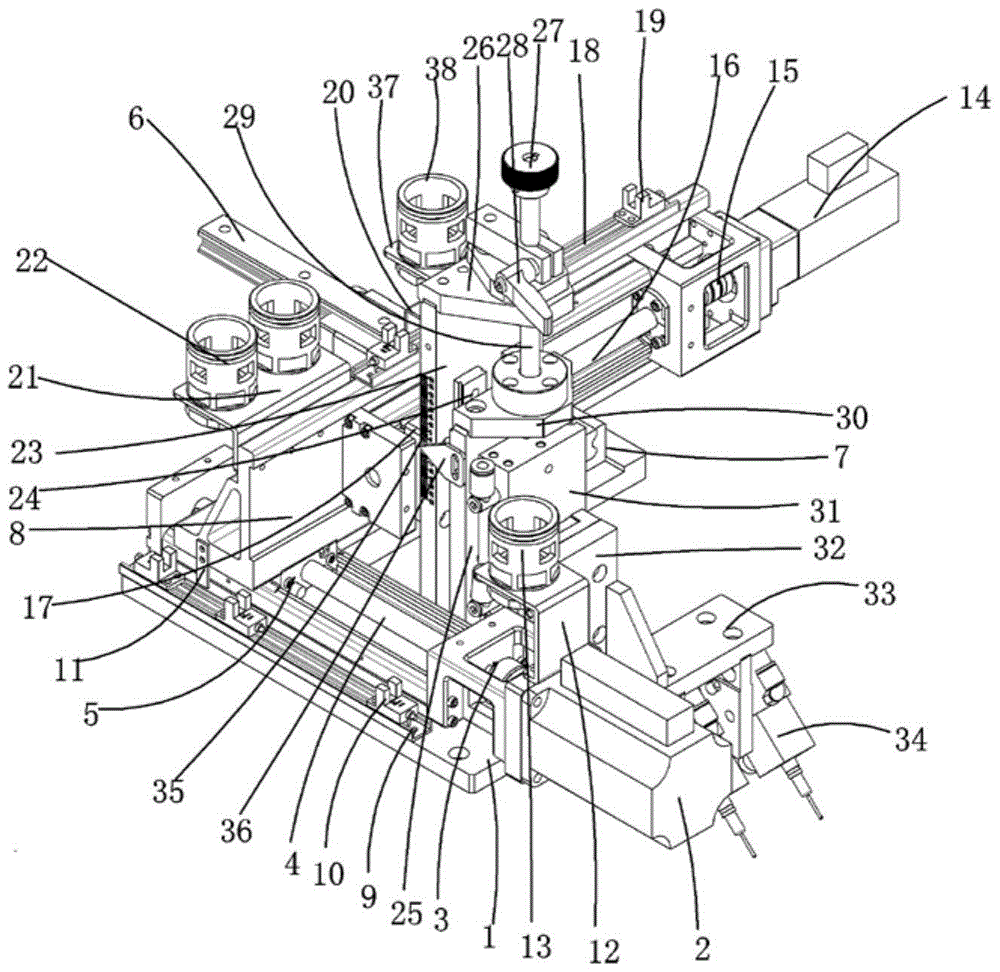

[0019] Examples, see attached figure 1 , a refueling mechanism, which includes an X-axis mechanism, a Y-axis mechanism and a refueling adjustment mechanism, the Y-axis mechanism is installed on the X-axis mechanism, the refueling adjustment mechanism is installed on the Y-axis mechanism, and the X-axis of the refueling adjustment mechanism The direction and the position of the Y-axis direction can be adjusted through the control of the X-axis mechanism and the Y-axis mechanism, and the adjustment is convenient and the position is accurate.

[0020] The X-axis mechanism includes an X-axis base 1, an X-axis motor 2, an X-axis coupling 3, an X-axis linear module 4, an X-axis linear module slider 5, an X-axis auxiliary slide rail 6, and an X-axis auxiliary Slider 7, XY-axis connecting angle 8, X-axis mounting bar 9, X-axis photoelectric sensor 10 and X-axis sensing sheet 11, the X-axis linear module and the X-axis mounting bar are respectively installed on the X-axis base, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com