A brake valve device

A brake valve, valve body technology, applied in the direction of brakes, brake components, control valves and air release valves, etc., can solve the problem of gas circulation, back pressure injection, expansion, guidance, uniform output, uneven working process, The air supply of the upper air valve and the lower air valve is not synchronized, and the maintenance or maintenance of the brake valve is difficult, so as to achieve the effect of light braking process, easy repair or maintenance, and reduced impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

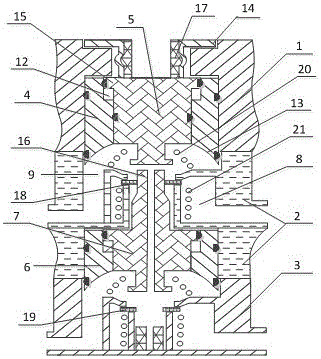

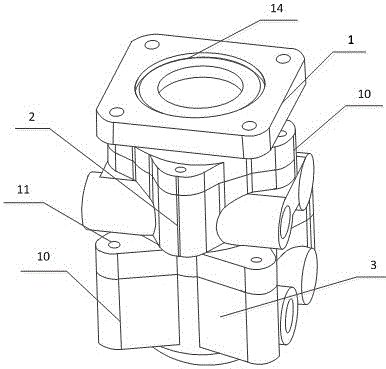

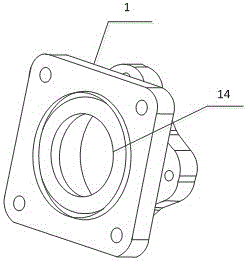

[0040] like Figure 1 to Figure 12 As shown in the figure, a brake valve device includes an upper cavity valve body 1, a middle cavity valve body 2 and a lower cavity valve body 3 which are connected in sequence and can be detached from each other, and the first piston which is sleeved in the lower end of the upper cavity valve body Outer shell 4 is slidably connected to the first piston 5 in the first piston outer shell, and the ejector rod seat 17 connected to the upper end of the first piston is sleeved in the second piston outer shell 6 in the lower end of the middle cavity valve body, and is slidably connected to the second The second piston 7 in the piston jacket, the upper gas storage valve 18 connected to the upper end of the second piston, the lower gas storage valve 19 installed in the valve body of the lower cavity, the lower end of the first piston is movably connected with the upper gas storage valve, The lower end of the second piston is movably connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com