Automobile collision buffer system based on magnetic control cement

A buffer system and automobile technology, which is applied in the field of automobile collision buffer system, can solve the problems of non-adaptive adjustment, etc., and achieve the effect of compact structure, small changes, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

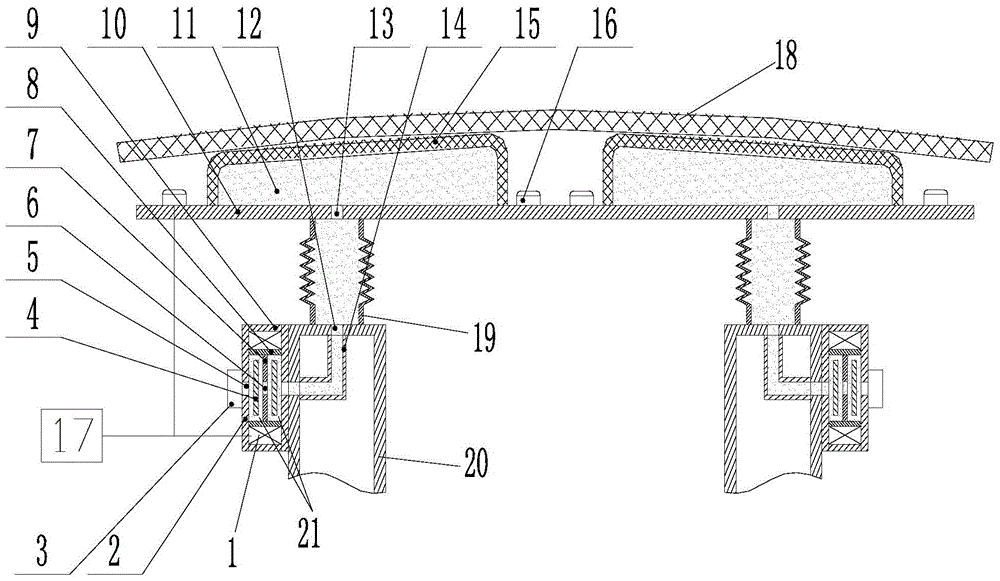

[0020] Such as figure 1 As shown, an automobile collision buffer system based on magnetic control cement includes: buffer capsule 15, bumper crush beam 19, automobile bumper shell 18, automobile longitudinal beam 20, anti-collision baffle 10, orifice (5, 6 , 12, 13), draft tube 14, end cover 2, excitation coil 1, excitation coil inner cylinder 8, excitation coil outer cylinder 9, isolation plate 4, buffer plate 7, pressure cover plate 3, detection device 16 and controller 17.

[0021] Such as figure 1 As shown, the buffer capsule 15 is arranged between the anti-collision baffle 10 and the bumper shell 18, and is sealed and installed on the outside of the anti-collision baffle 10 to form a first-level magnetic control cement buffer container; one end of the bumper crush beam 19 is fixed It is sealed and installed on the inner side of the anti-collision baffle 10, and the other end is hermetically connected with the automobile longitudinal beam 20 to form a second-level magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com