Rapid forming method based on double-forming head

A forming method and forming head technology, which is applied in the field of rapid prototyping based on double forming heads, can solve the problems of difficult balance between workpiece surface quality and overall processing efficiency, and achieve high-precision and high-efficiency forming by improving surface quality and overall processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is the application of the method of the present invention in the field of SLA. Using the method of the present invention, laser emitters with two different frequencies of low-light and ultraviolet light can be used to cooperate to cure the interior of the solid part with ultraviolet light, improve work efficiency, and achieve low-light curing. The surface improves the precision, which not only meets the current demand for precision, but also improves work efficiency, and can also reduce the cost of mechanical equipment.

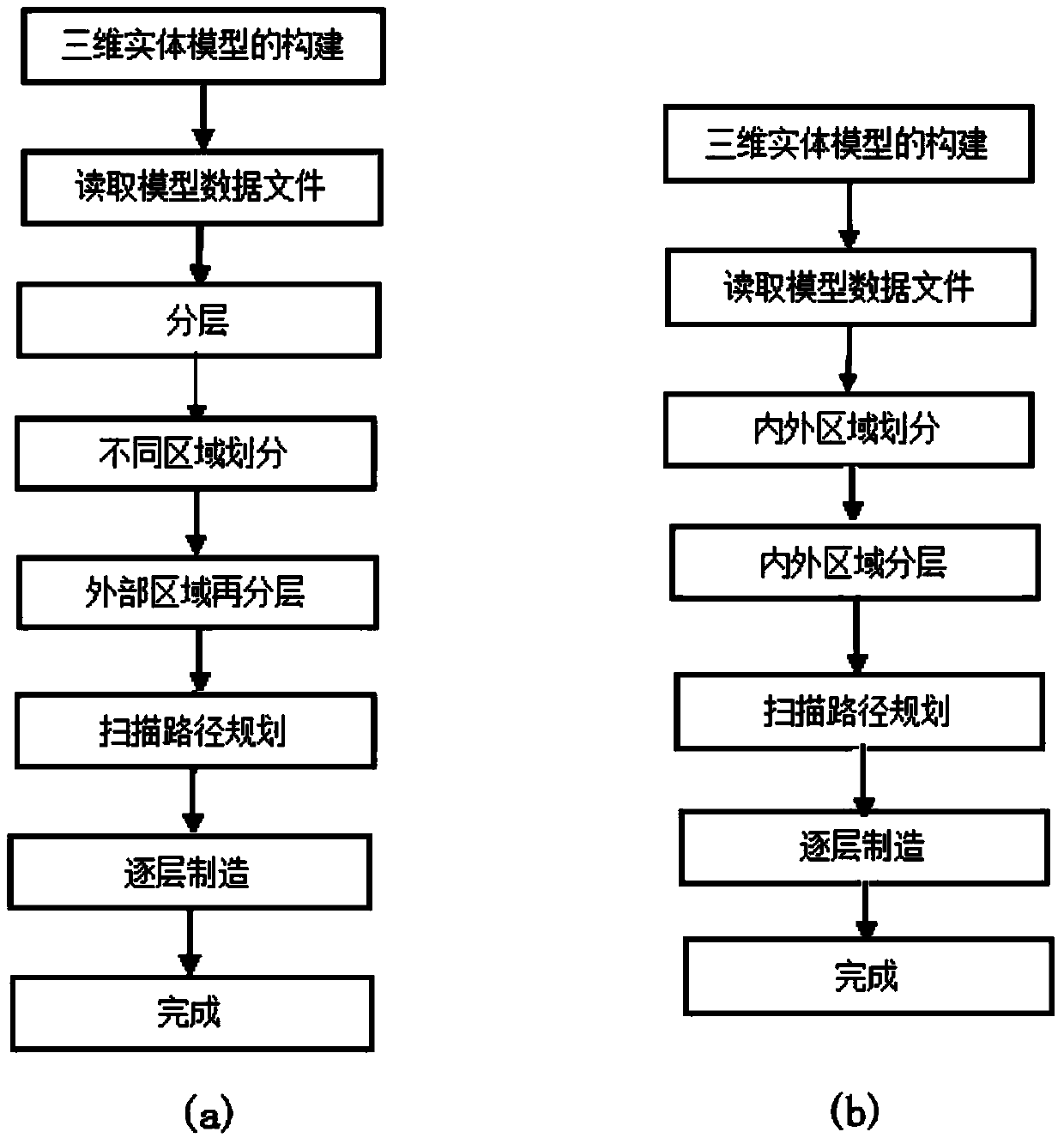

[0047] In this embodiment, the rapid prototyping method based on double forming heads is taken as an example, which is layered first and then partitioned. The specific steps are as follows:

[0048] (1) Firstly, the 3D solid model is constructed by 3D solid modeling software, and then the 3D solid model is output in STL file format. The STL file is a file format that uses triangular patches to represent the 3D solid model. It is surround...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com