Automatic paint spraying system

An automatic painting and recovery system technology, applied in the direction of spraying devices, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of unfixed paint spraying positions, difficult to recycle paint, and high skill requirements for workers, so as to reduce occupational injuries and skill requirements, high paint utilization rate, and the effect of improving the site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

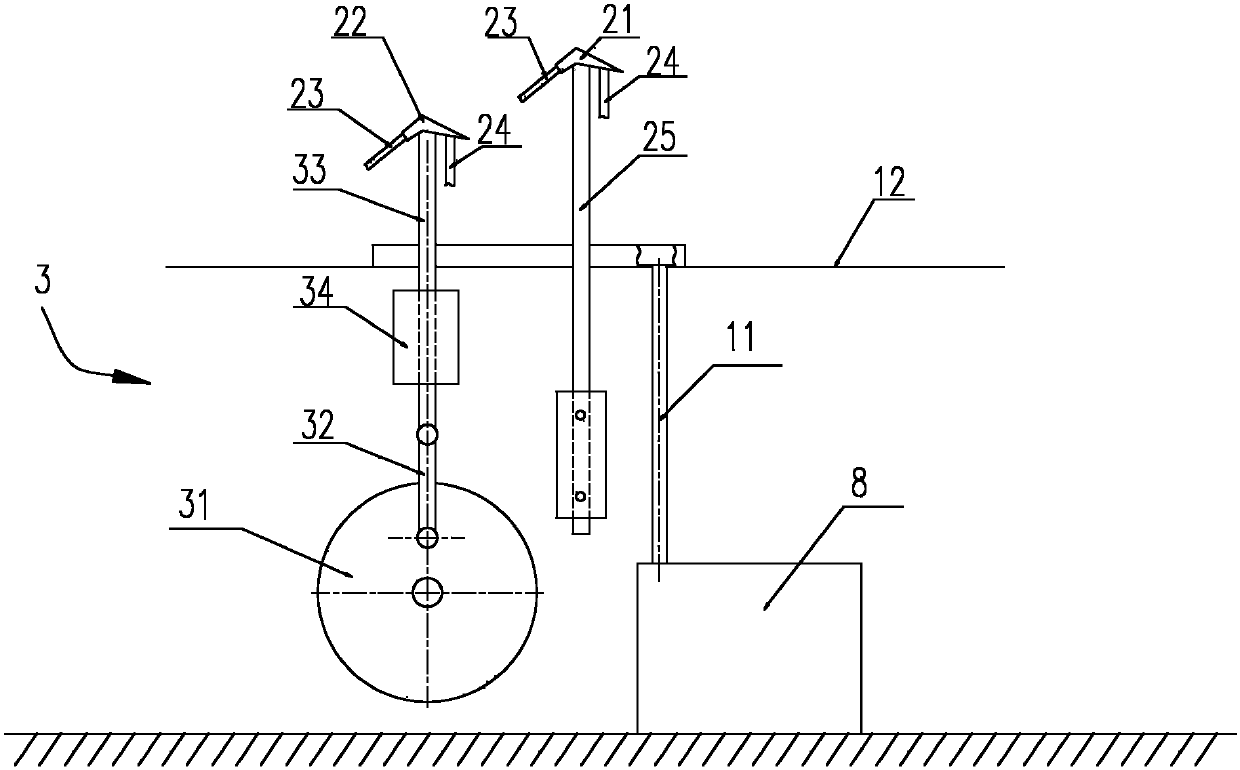

[0026] like figure 1 A kind of automatic painting system shown, comprises frame 11, painting mechanism 2 and plate chain conveyer belt 12 installed on the frame 11, the frame 1 is equipped with necessary guard guards, the painting mechanism 2. It is arranged on the side of the plate chain conveyor belt 12, and a plurality of workpiece bearing seats 4 are vertically installed on the plate chain conveyor belt 12, and the plurality of workpiece bearing seats 4 are driven by the revolution mechanism 5 together with the plate chain conveyor belt 12 It revolves along the frame 11, and its revolution axis is parallel to the ground. When the workpiece bearing seat 4 moves to the relative position of the painting mechanism 2, it rotates under the drive of the rotation mechanism 6. A cleaning machine is installed directly below the running route of the plate chain conveyor belt 12. Mechanism 9, the cleaning mechanism 9 deviates from the painting mechanism 2 side.

[0027] figure 2 Th...

Embodiment 2

[0036] like Figure 9 As shown, an automatic paint spraying system includes a circulating conveying device 1 and a painting mechanism 2 arranged on one side of the circulating conveying device 1. Static spray gun 22, the moving spray gun 22 is driven by the spray gun driving device 3 to reciprocate up and down, the circular conveying device 1 includes a frame 11 and a circular turntable 13 rotatably installed on the frame 11, the turntable 13 The outer edge is provided with an outward flanging 14, and the workpiece bearing seat 4 is rotatably installed on the flanging 14, and the turntable 13 is arranged obliquely. A paint mist recovery system 7 is provided.

[0037] A rotating shaft 15 is fixed at the center of the turntable 13, and a bevel gear 16 is sheathed at the end of the turntable 15. The revolution motor 51 is arranged under the turntable 13, and its output power is decelerated by a reducer 52 and then transmitted to the bevel gear 16 to drive the turntable 15 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com