A flat film scraping machine

A flat, scraping membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems affecting the accuracy of ultrafiltration membranes, the support plate is easily damaged, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

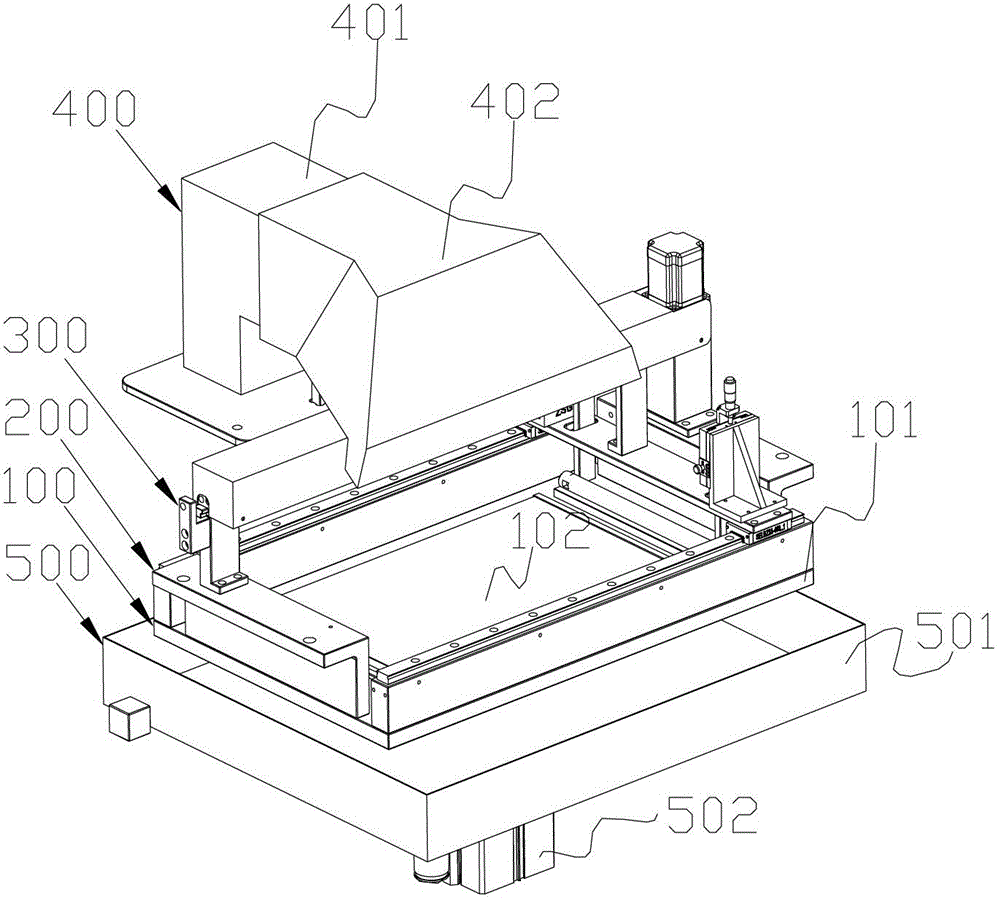

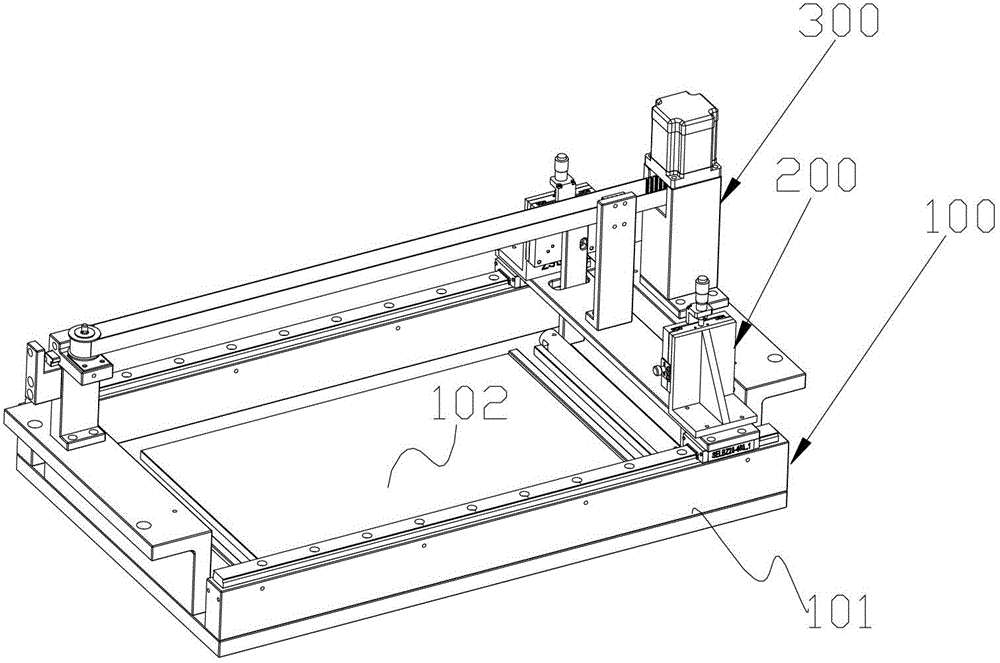

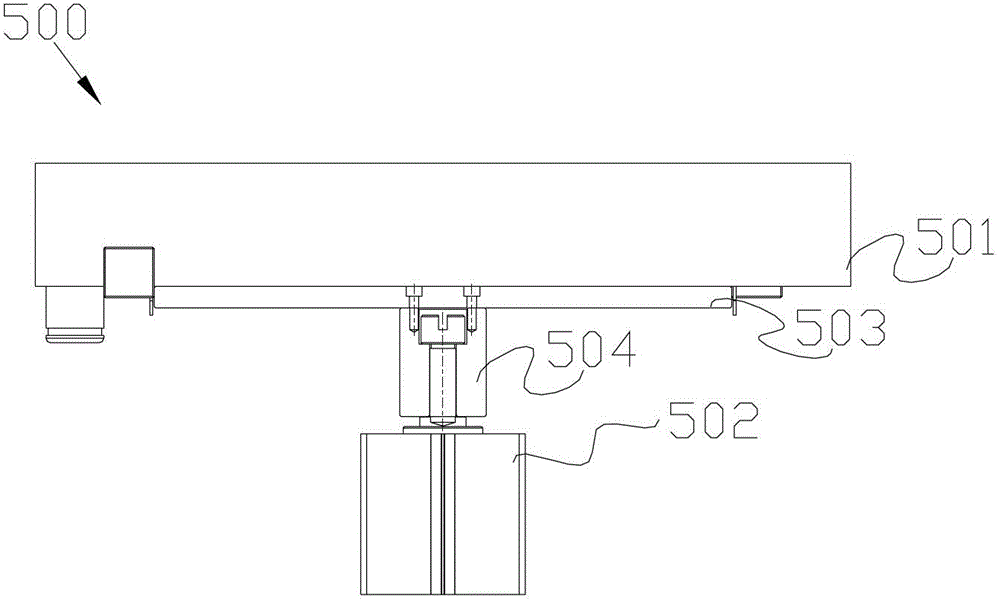

[0025] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

[0026] After research, the inventor found that the existing flat-plate film scraping machine needs to be supported by a support plate when scraping the film, and the thickness accuracy of the support plate must be controlled at μ level to ensure the accuracy of the completed ultrafiltration membrane. At the same time, since the support plate needs to be moved up and down, and the support plate needs to be dried after the membrane body is fixed, in order to improve the deformation resistance and high temperature resistance of the support plate, it is necessary to take into account the thickness and materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com