An electrostatic induction generator

An electrostatic induction and generator technology, applied in the direction of induction generators, etc., can solve the problems of poor long-distance transmission of direct current, the use of direct current generators is not very common, and the practical significance is not large, so as to avoid the consumption of a large amount of electric energy, the structure is simple, the Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

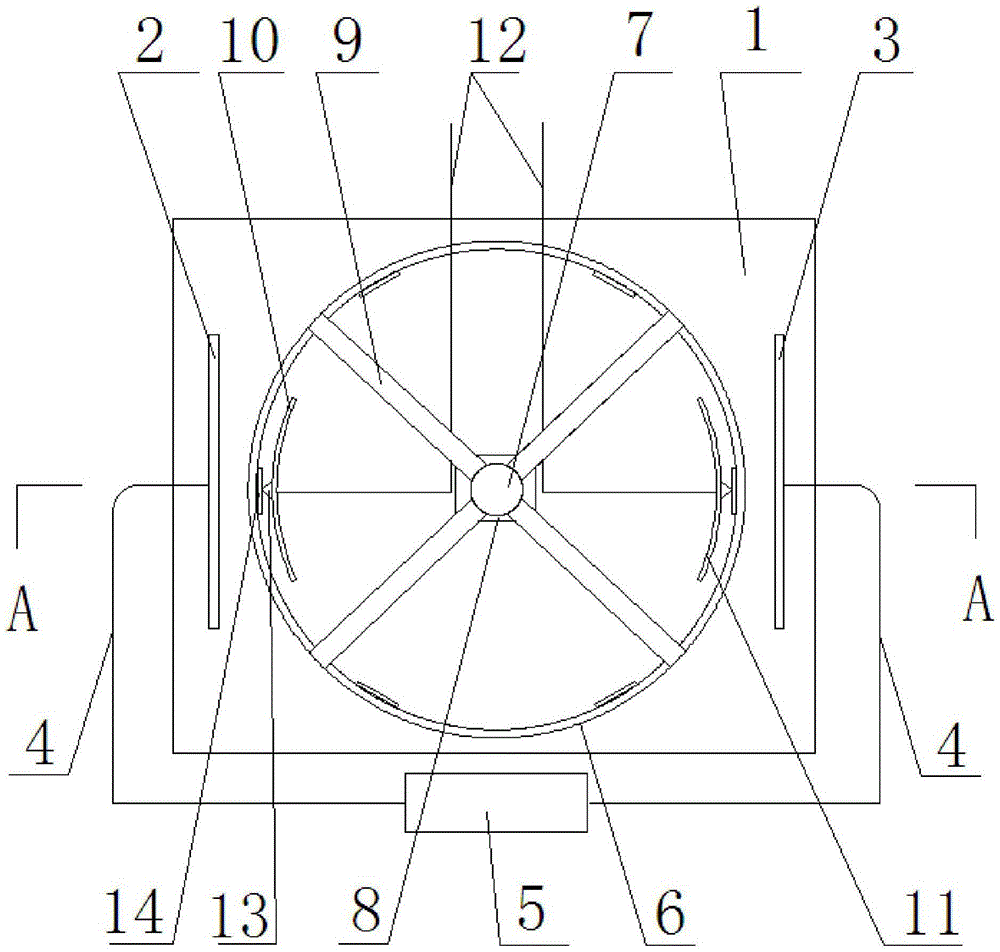

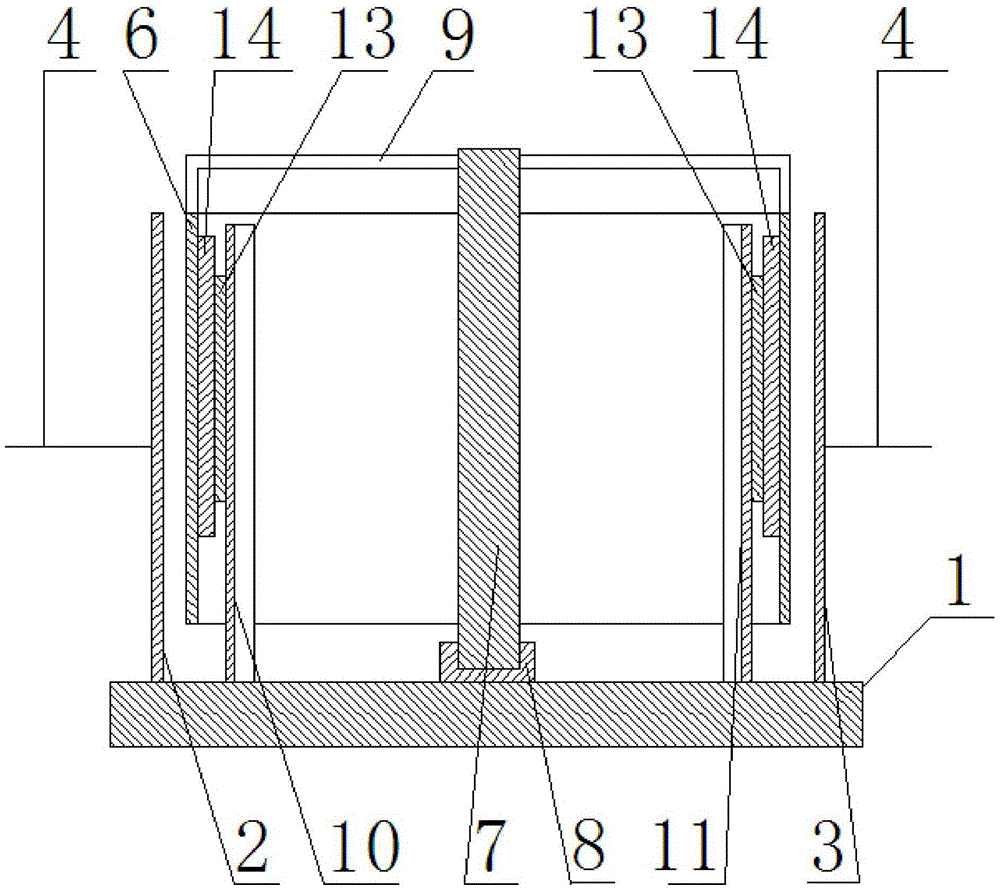

[0023] Such as figure 1 , figure 2 As shown, this embodiment includes an insulating base 1, on which a first metal plate 2 and a second metal plate 3 are vertically arranged, and the first metal plate 2 and the second metal plate 3 The first metal plate 2 is connected to the positive pole of the DC high-voltage power supply 5 through the wire 4, and the second metal plate 3 is connected to the negative pole of the DC high-voltage power supply 5 through the wire 4. The first metal plate 2 and the second An insulating drum 6 is arranged between the metal plates 3, and a central shaft 7 is arranged at the center of the drum 6, and the central shaft 7 is fixed on the base 1 through a bearing seat 8, and the central shaft 7 and The drums 6 are all set up vertically, the bottom end of the central shaft 7 is arranged on the bearing seat 8 on the base 1, and the top end of the central shaft 7 passes through the support 9 and the drum 6 The top end of the drum 6 is fixed, and a gap ...

Embodiment 2

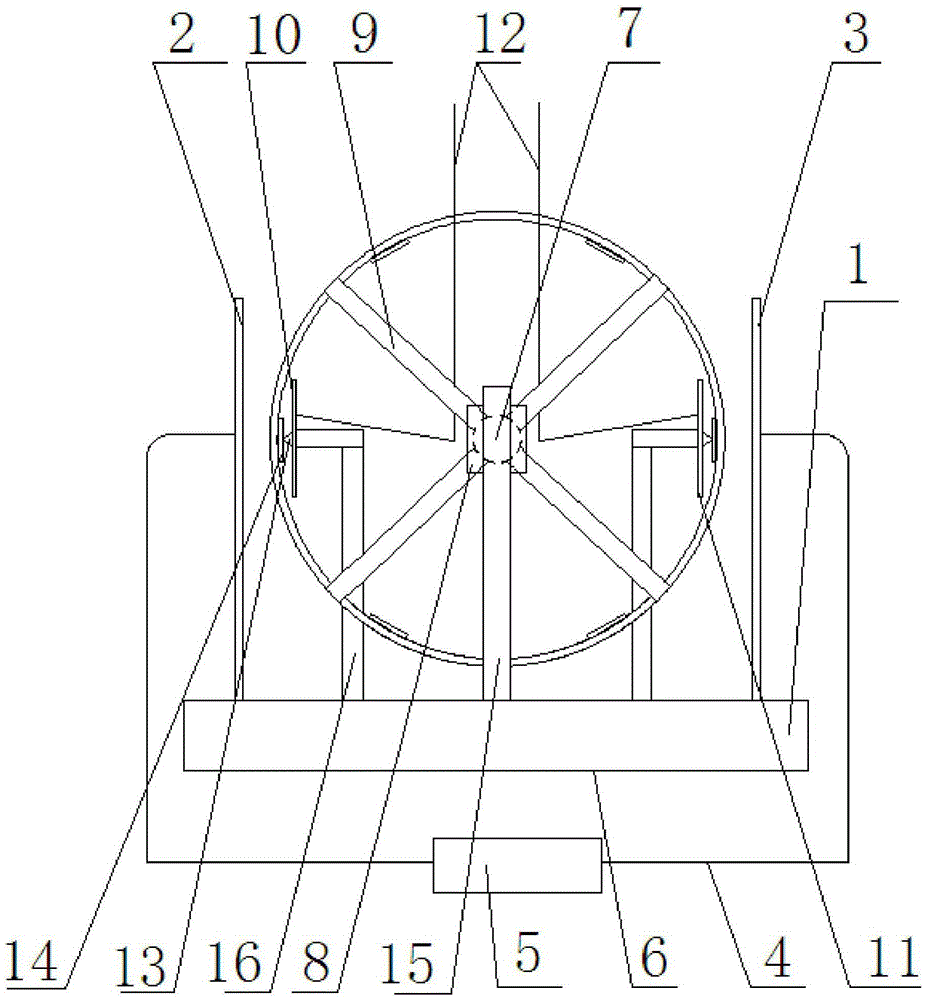

[0026]This embodiment includes an insulated base 1, on which a first metal plate 2 and a second metal plate 3 are vertically arranged, and the first metal plate 2 and the second metal plate 3 are arranged in parallel and opposite each other , the first metal plate 2 is connected to the positive pole of the DC high-voltage power supply 5 through a wire 4, the second metal plate 3 is connected to the negative pole of the DC high-voltage power supply 5 through a wire 4, and the first metal plate 2 and the second metal plate 3 An insulated drum 6 is arranged between them, and a central shaft 7 is arranged at the center of the drum 6, and the central shaft 7 is fixed on the base 1 through a bearing seat 8, and the central shaft 7 and the rotating drum The barrel 6 is arranged horizontally, and both ends of the central shaft 7 are provided with central shaft struts 15, and the bottom ends of the two central shaft struts 15 are fixed on the base 1, and the two central shaft struts 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com