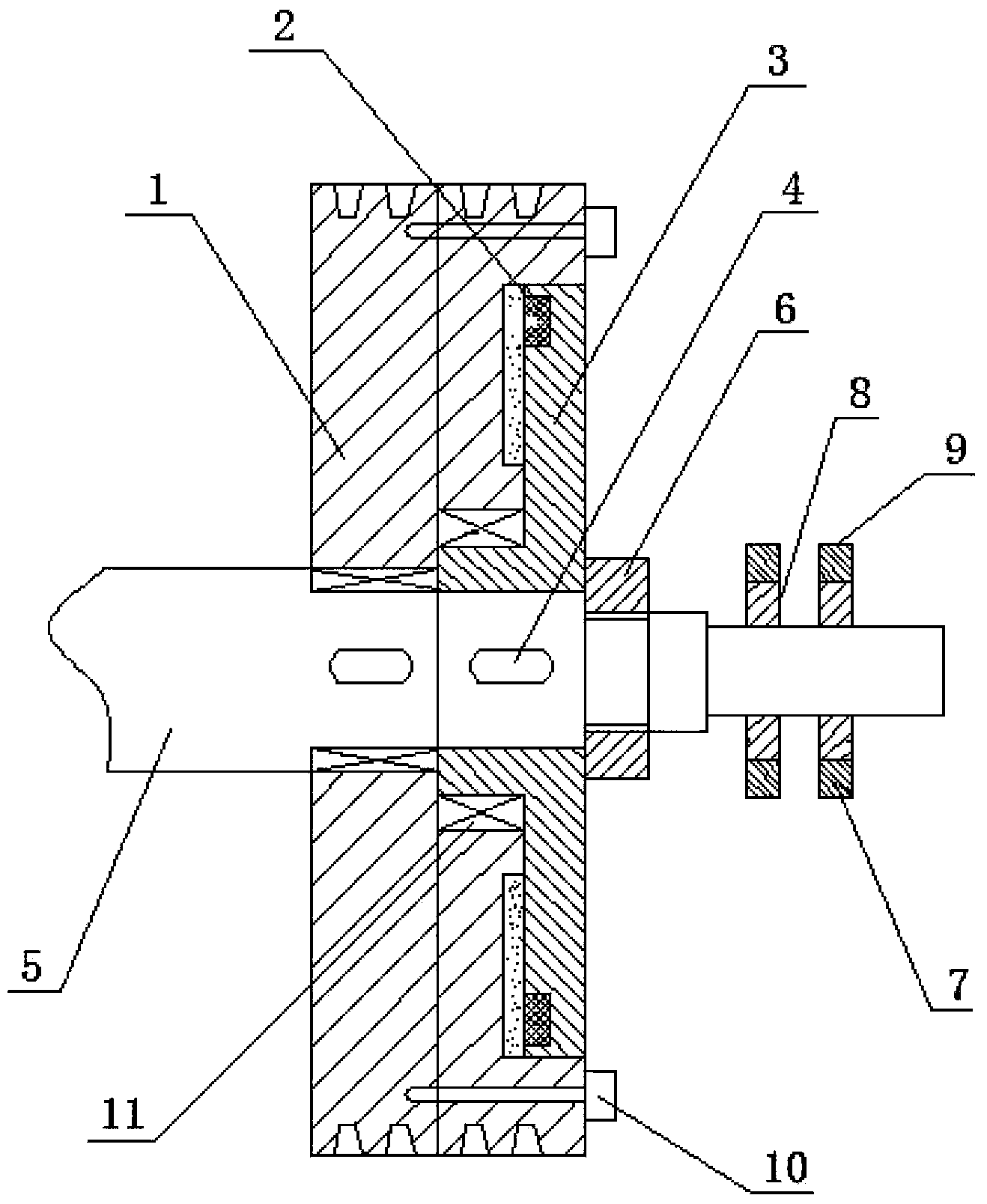

Novel forging press clutch brake mechanism

A technology of brakes and forging presses, which is applied to the driving device of forging presses, non-mechanical drive clutches, clutches, etc. It can solve the problems of high-speed forging presses, large parts space, and high energy consumption, etc., and achieve rapid combination and separation Reliable, less transmission inertia, overcome the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The clutch brake mechanism has a driving flywheel (1), the driving flywheel (1) is installed on the hollow shaft of the brake driving disc (3) through the positioning bearing (11), and the brake driving disc (3) is installed on the crankshaft (5) through the hollow shaft One end, fixed by the positioning key (4), the electromagnetic coil (2) is installed in the groove of the brake driving disc (3) and the driving flywheel (1), between the brake driving disc (3) and the driving flywheel (1) The space in the space is filled with electromagnetic material (10), and a fixed nut (6) is installed on the external thread of the crankshaft (5), and the brake drive disc (3) and the driving flywheel (1) are connected to the crankshaft ( 5) Upper docking, at one end of the crankshaft (5), an insulating ring (8) and a conductive plate (9) are respectively provided, the conductive ring (7) is connected to the conductive plate (9), and the conductive ring (7) is installed with The elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com