Steel frame prestressed waste tire runway

A waste tire and prestressing technology, which is applied to roads, roads, pavement, etc., can solve the problems of high recycling cost, complicated process, and high raw material processing cost, so as to improve the consistency of strength, save building materials, and improve running speed. The effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

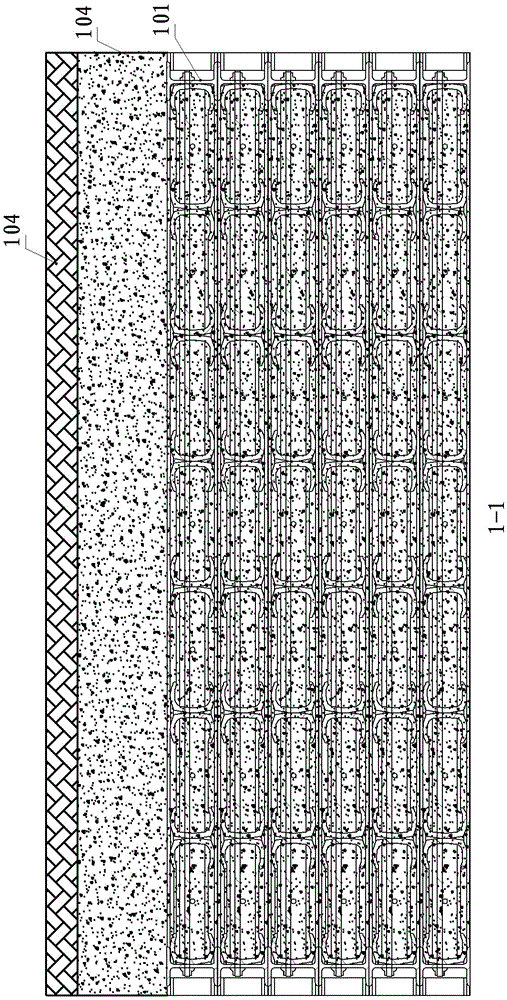

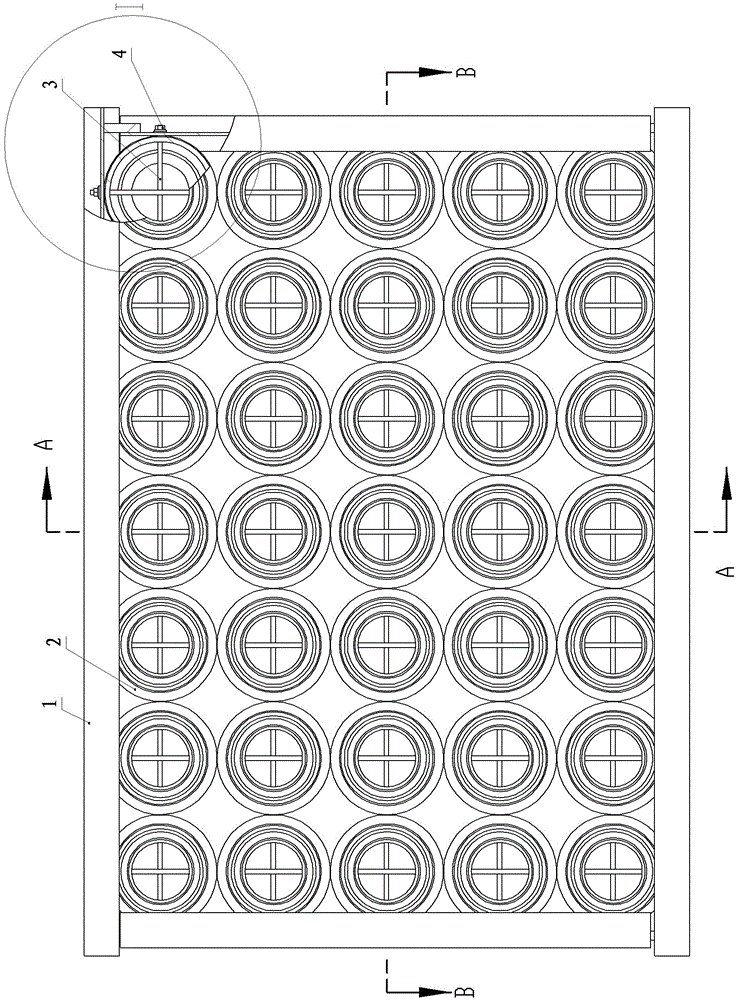

[0020] Example: see Figure 1-Figure 9 , a steel frame prestressed waste tire runway in the figure, including the runway foundation made of prestressed frame, filler cushion, plastic runway surface,

[0021] The runway foundation made of the prestressed frame includes several layers of steel frame prestressed mesh, and the steel frame prestressed mesh includes several square scrap tires arranged vertically and horizontally, surrounded by scrap tires Shaped steel frame, the prestressed steel strand crosses the waste tires and the opposite shaped steel vertically and horizontally, and the steel strand applies prestress through the tension nut outside the shaped steel. The side is snapped into the inner groove of the H-shaped steel, the steel strand passes through the web in the middle of the H-shaped steel, and the tension nut is located in the outer groove of the H-shaped steel and is close to the outer surface of the H-shaped steel web. One set of opposite sides of the H-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com