Chitosan quaternary ammonium salt product and preparation method thereof

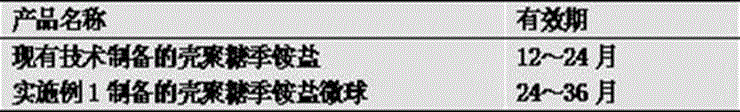

A technology of chitosan quaternary ammonium salt and trimethylamine hydrochloride is applied in the field of medical devices and can solve the problems of poor stability, low substitution degree of chitosan quaternary ammonium salt, weak antibacterial activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 100g of epichlorohydrin and 130g of trimethylamine hydrochloride, put them in a reaction kettle, add 400g of 30% sodium hydroxide solution, stir for 2 hours, and make 2,3-epoxypropyltrimethylammonium chloride solution; Take 80g of chitosan, put it in an ultrasonic reactor, add 400g of isopropanol, 300g of 30% sodium hydroxide solution, 50g of sodium chloride, 10g of aluminum chloride, stir for 1 hour, add 2,3-epoxypropyltri Methylammonium chloride solution, select ultrasonic frequency 37kHz, heat up to 78°C, react for 3 hours, add 10% hydrochloric acid to adjust the pH value to 7.0, filter with suction, add 1000g of absolute ethanol to the filter cake, stir for 2 hours, filter with suction, filter Put the cake in an ultrasonic reaction kettle, add 1200 g of water, 150 g of sodium trethalate, select an ultrasonic frequency of 40 kHz, react for 2 hours, and spray dry to obtain chitosan quaternary ammonium salt microspheres.

specific Embodiment 2

[0028] Take 100g of epichlorohydrin and 130g of trimethylamine hydrochloride, put them in a reaction kettle, add 400g of 30% sodium hydroxide solution, stir for 2 hours, and make 2,3-epoxypropyltrimethylammonium chloride solution; Take 80g of chitosan, put it in an ultrasonic reactor, add 400g of isopropanol, 300g of 30% sodium hydroxide solution, 50g of sodium chloride, 10g of aluminum chloride, stir for 1 hour, add 2,3-epoxypropyltri Methylammonium chloride solution, select ultrasonic frequency 37kHz, heat up to 78°C, react for 3 hours, add 10% hydrochloric acid to adjust the pH value to 7.0, filter with suction, add 1000g of absolute ethanol to the filter cake, stir for 2 hours, filter with suction, filter Put the cake in an ultrasonic reaction kettle, add 1200g of water, 150g of sodium trethalate, select the ultrasonic frequency of 40kHz, react for 2 hours, add 1000kg of pure water, stir for 1 hour, pour it into a nasal sprayer, and make chitosan quaternary ammonium salt N...

Embodiment 3

[0030] Take 100g of epichlorohydrin and 130g of trimethylamine hydrochloride, put them in a reaction kettle, add 400g of 30% sodium hydroxide solution, stir for 2 hours, and make 2,3-epoxypropyltrimethylammonium chloride solution; Take 80g of chitosan, put it in an ultrasonic reactor, add 400g of isopropanol, 300g of 30% sodium hydroxide solution, 50g of sodium chloride, 10g of aluminum chloride, stir for 1 hour, add 2,3-epoxypropyltri Methylammonium chloride solution, select ultrasonic frequency 37kHz, heat up to 78°C, react for 3 hours, add 10% hydrochloric acid to adjust the pH value to 7.0, filter with suction, add 1000g of absolute ethanol to the filter cake, stir for 2 hours, filter with suction, filter Put the cake in an ultrasonic reactor, add 1200g of water, 150g of sodium trehalate, select the ultrasonic frequency of 40kHz, react for 2 hours, add 1000kg of pure water, stir for 1 hour, pour it into a rotary arm sprayer, and make chitosan quaternary ammonium salt Oral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com