A reactor for liquid-solid two-phase continuous reaction and on-line separation

A technology of reactors and separators, applied in the direction of filtration separation, separation methods, fixed filter cartridge filters, etc., can solve the problems of residence time and narrow residence time distribution, reduce subsequent processing links, increase product yield, and improve The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

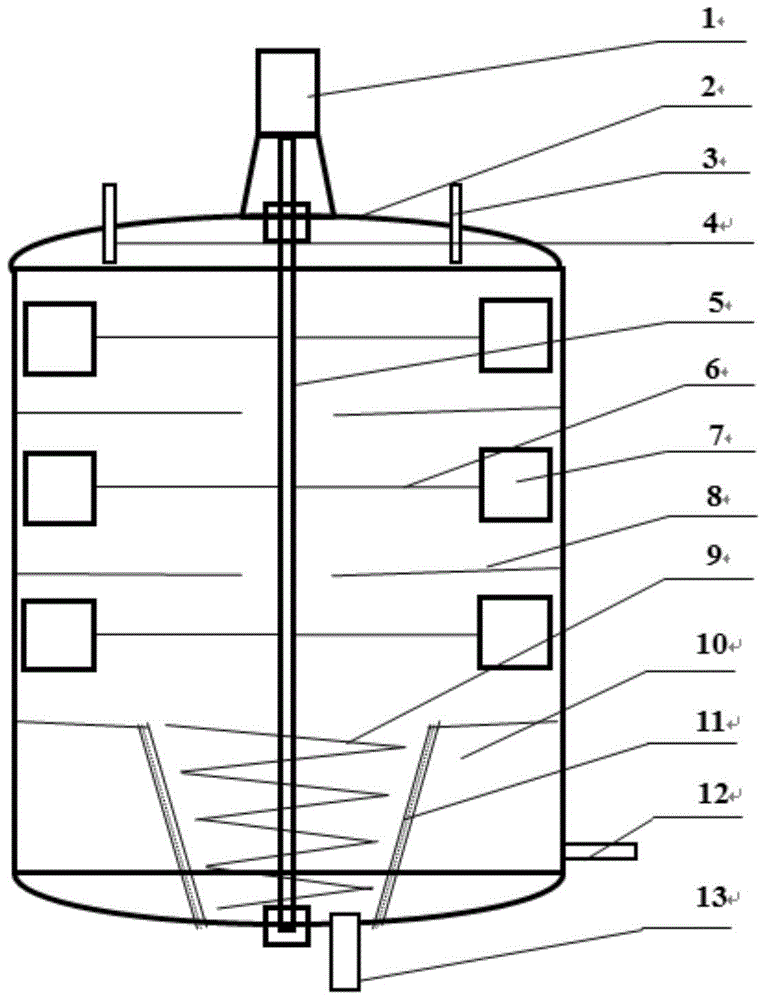

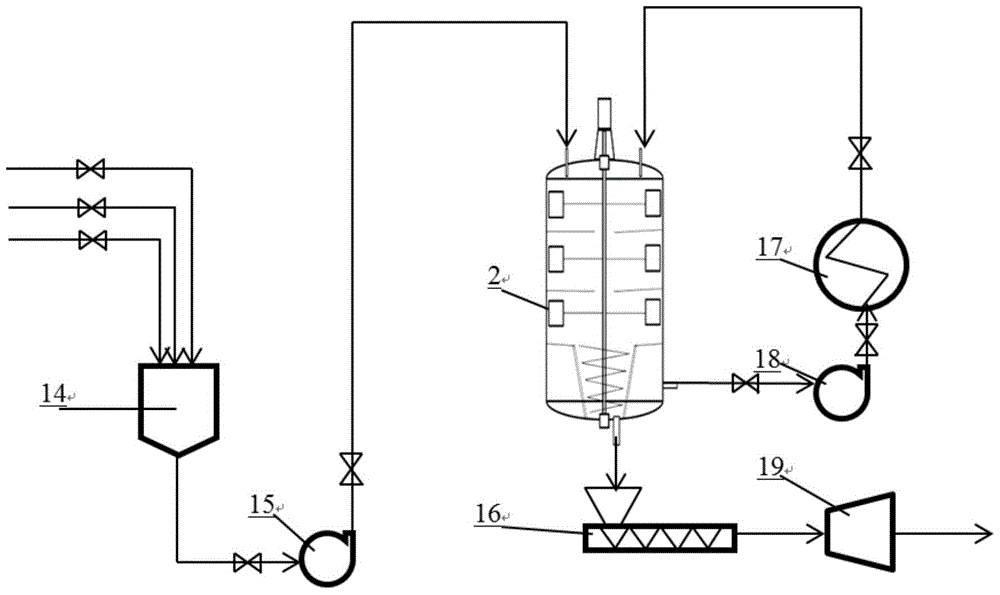

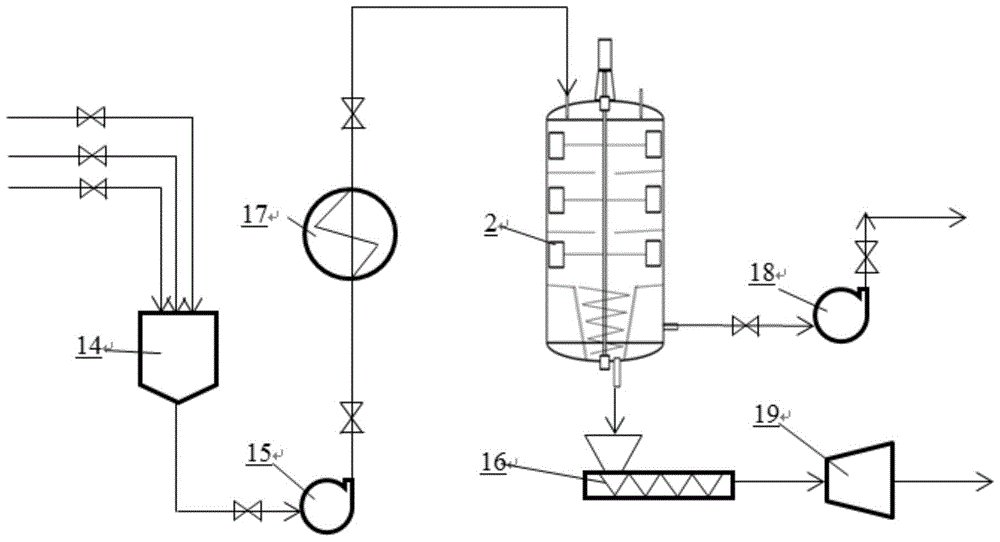

[0018] figure 1 It is a schematic diagram of the structural principle of the liquid-solid phase continuous reactor of the present invention. The reactor is divided into upper and lower parts, the upper part is a baffled continuous reactor, and the lower part is an online separator; the reactor contains a reactor cylinder 2 , moving deflector 6 and static deflector 8; there are at least two feed inlets on the upper part of the baffled continuous reactor, which are respectively the raw material inlet 3 and the circulating fluid inlet 4, which are used to feed the raw material slurry and circulating fluid into the reactor . A rotating shaft 5 penetrating up and down is provided in the reactor cylinder, which is driven by the motor 1 and fixed on the reactor cylinder through bearings and seals; the moving deflector 6 is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com