Fly maggot separator

A separation machine and fly maggot technology, applied in animal husbandry and other directions, can solve the problems of time-consuming, labor-intensive, labor-intensive, and poor working environment for workers, and achieve the effect of improving separation efficiency and reducing labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

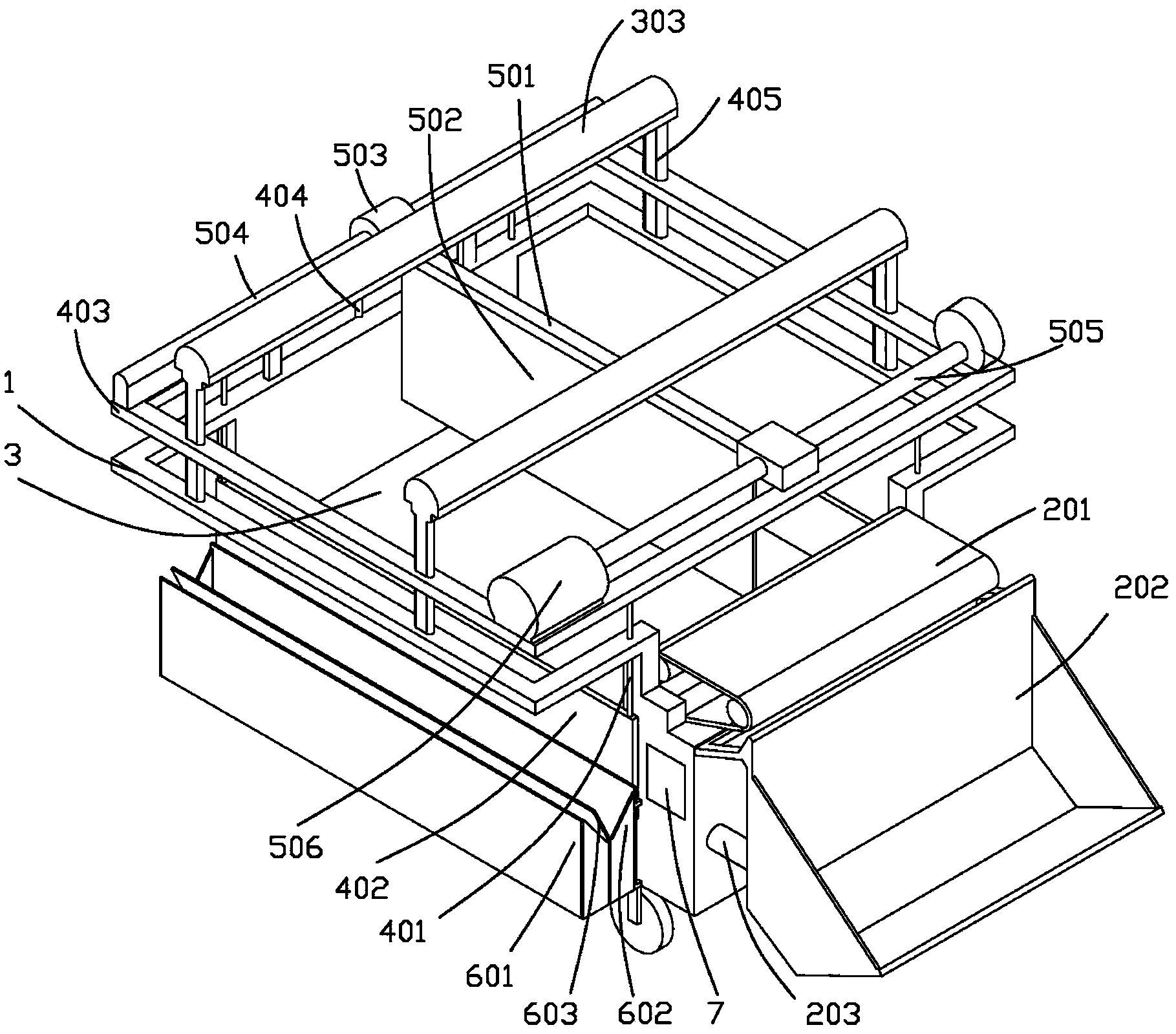

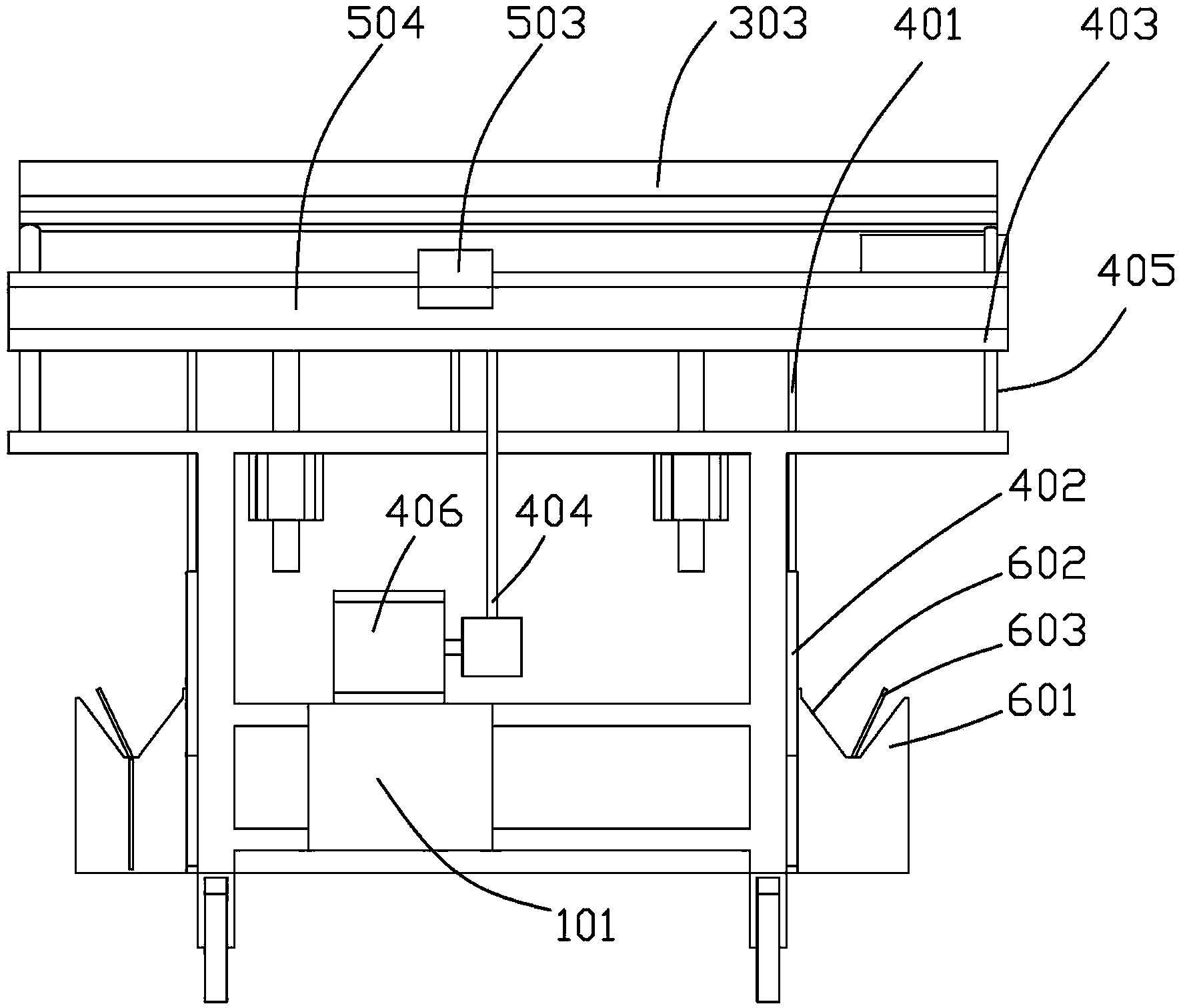

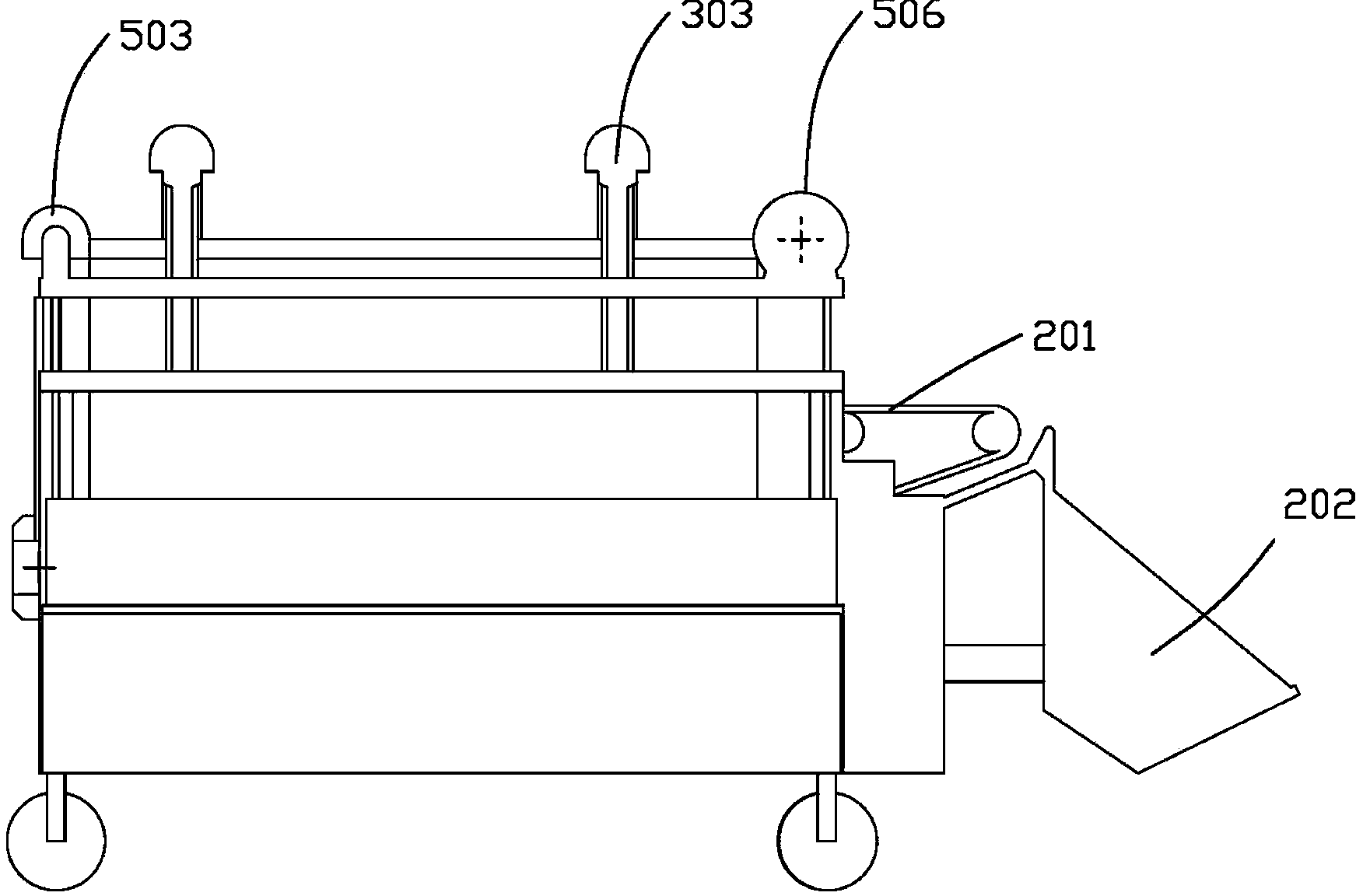

[0023] See Figure 1-Figure 4 , a fly maggot separator, the fly maggot separator comprises a car body 1 and a feeding device located at its front end, the feeding device is fixed on the car body 1 for conveying the groove-shaped feed bin 3 of fly maggots and slag The front ends are connected, and a vertical lifting device is provided on the silo 3. The top of the lifting device is also provided with a cleaning device that can reciprocate perpendicularly to the moving direction of the car body. The two ends of the lifting device are also suspended and connected with gates 402 , the gate 402 is close to the end faces of the notches at both ends of the feed bin 3 , and the lower sides of the end faces are respectively provided with collecting devices fixed on the vehicle body.

[0024] See Figure 1-Figure 4 The feeding device includes a first conveyor belt 201 driven by a first motor. The front end of the first conveyor belt 201 is also provided with a reversible first material...

Embodiment 2

[0033] working principle

[0034] See Figure 1-Figure 4Since the first and second feeding devices are only different in feeding methods, they do not affect the principle of fly maggot separation. Therefore, in this embodiment, the first feeding device is used as an illustration, and the description of the second feeding device is omitted. And described in detail as follows.

[0035] The invention is a device for mechanically separating the fly maggot from the feed slag after the biotransformation of the fly maggot cultured by the biomass waste, and is used for replacing manual cleaning and separation. The present invention utilizes the biological habit of natural pupation after the fly maggot matures, and needs to pupate in a dark and dry environment, and separates the culture medium of the fly larva growth stage (3-15 days) from the fly maggot The first shovel 202 in the feeding device at the front end of the machine scoops up the culture substrate, and puts the culture su...

Embodiment 3

[0039] In combination with embodiment 1 and embodiment 2, such as Figure 5 As shown, another fly maggot separator of the present invention is provided with all parts of the fly maggot separator as described in Embodiment 1 and Embodiment 2, and the bottom of the bin 3 is also provided with an openable and closable bottom plate 301 , the bottom plate 301 is connected to the fifth motor 302 through the worm gear and the gear set, and the fifth motor 302 is electrically connected to the control device. When the number of fly maggots is large, the separated fly maggots are separated from the bottom of the fly maggot separator by means of bottom discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com