Fan Stator Inserter

A paper inserting machine and stator technology, applied in the direction of laying solid insulation, etc., can solve the problems of increasing equipment investment, falling and hurting people, fixing fan stators, etc., achieving the effects of reducing driving force requirements, ensuring positioning progress, and reducing rotational resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

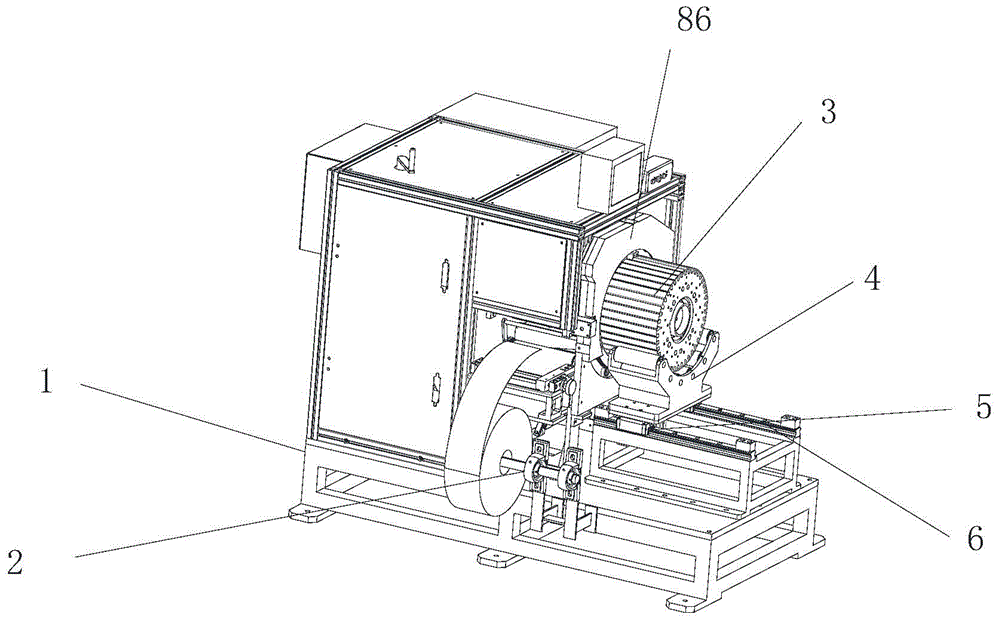

[0030] The present invention will be further described below in conjunction with the drawings.

[0031] Such as Figure 1 to Figure 9 The fan stator paper inserting machine shown includes a frame 1, a paper feeding mechanism 9 is arranged in the middle of the frame 1, and an insulating paper placing mechanism is arranged on the frame on the side of the paper feeding mechanism, and the insulating paper enters the paper feeding mechanism , The paper feeding mechanism folds the edges of the insulating paper and feeds the molded insulating paper into the forming mechanism. The paper feeding mechanism is a commonly used paper feeding mechanism in the field, so it is not described in detail in this application. The frame at the end of 9 is provided with a forming mechanism, the frame on the right side of the forming mechanism is provided with an indexing mechanism, and the frame on the left side of the forming mechanism is provided with a power device for driving the paper feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com