A return spring and a static contact device using the return spring

A technology of return spring and static contact, applied in the field of static contact device and return spring, can solve the problems of sudden change of stress of static contact finger and unstable change of force, so as to reduce stress, improve deformation strength and beautiful appearance of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

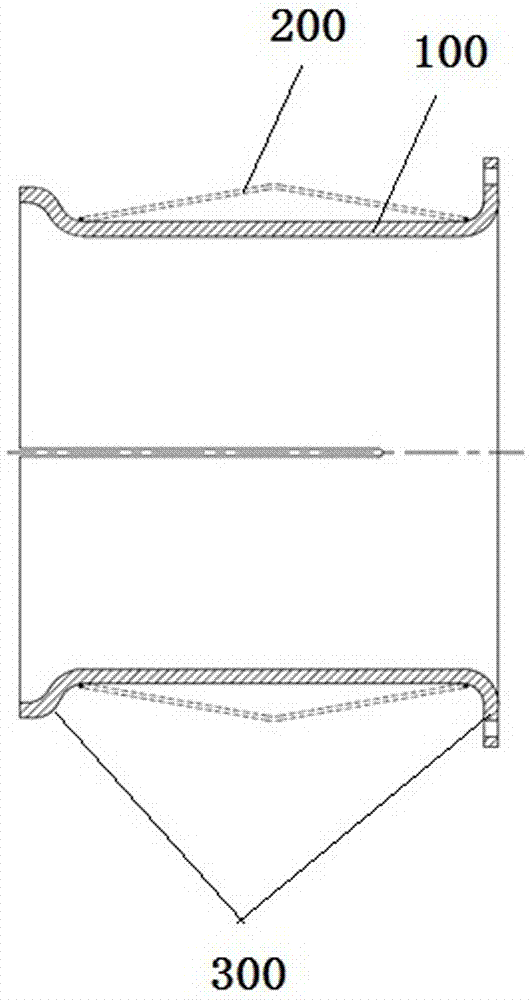

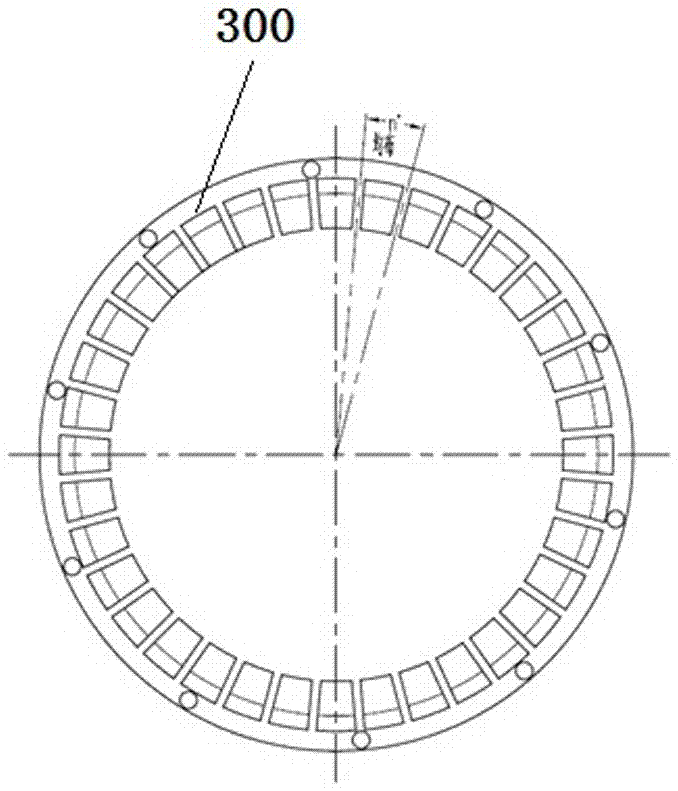

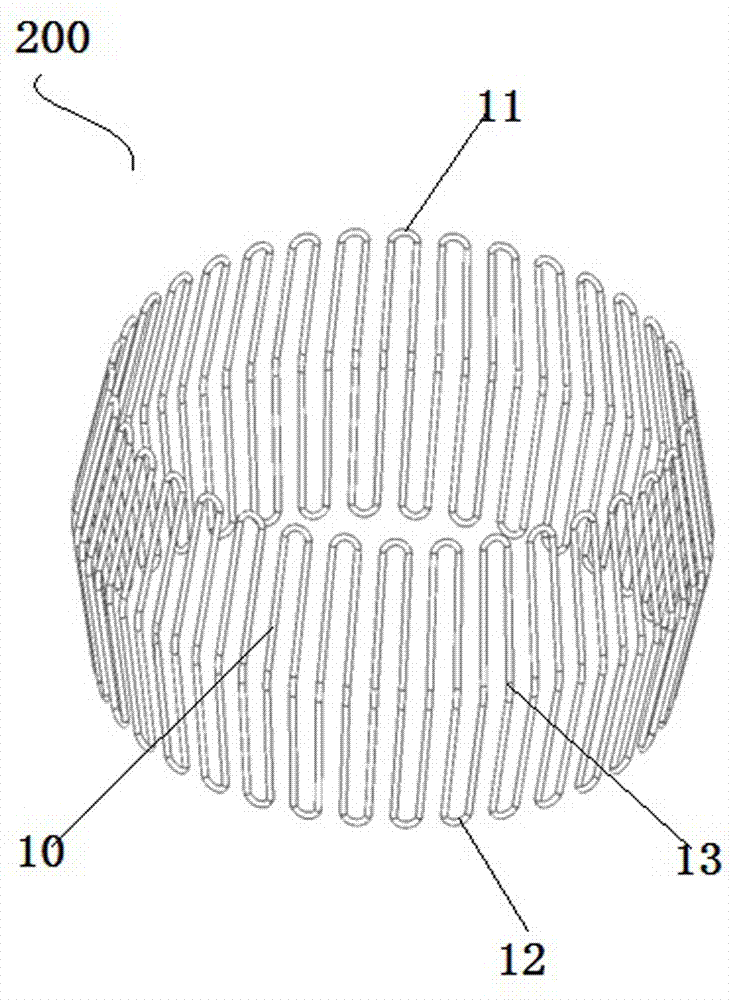

[0025] Such as Figure 1 to Figure 5 As shown, an embodiment of a static contact device, the static contact device in this embodiment includes a static contact body and an elastic static contact finger 100 with one end fixed on the static contact body, the elastic static contact finger 100 A return spring 200 is set on the outer side of the circumferential direction, and the return spring 200 here is a snake-shaped spring sleeve formed by bending and folding a spring wire 10 alternately in forward and reverse directions and welding the end and tail of the spring wire 10. The cross-section is circular, and the wire segment corresponding to the axial end of the serpentine spring sleeve on the spring wire 10 is the first curved segment 11, and the wire segment corresponding to the other axial end of the serpentine spring sleeve is the second curved segment 12. The curved section 11 and the second curved section 12 are U-shaped, and the wire section 13 between the first and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com