Bi-directional high load-bearing capacity wear-resistant mechanism

A high-load-bearing, wear-resistant lining technology, applied in the aviation field, can solve the problems of body structure wear and motion mechanism that cannot meet the design and use requirements, and achieve self-lubricating, large practical application value, and easy maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0015] See figure 1 . The high-load-bearing double-sided self-lubricating composite gasket (1) used in the present invention is a composite structural product. The surface layer is a self-lubricating fabric (1-1), and the middle is a metal substrate (1-2). In the process, it plays a role of reducing friction and lubricating.

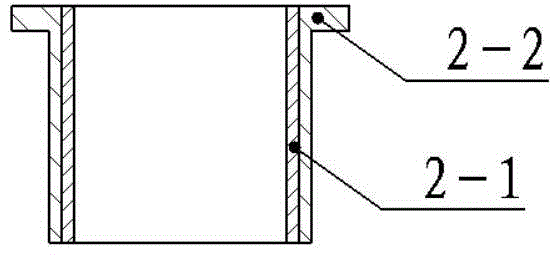

[0016] See figure 2 . The self-lubricating wear-resistant bushing (2) used in the present invention is a composite structural product, the inner surface of the shaft hole is self-lubricating fabric (2-1), the rest is metal substrate (2-2), and the self-lubricating fabric slides In the process, it plays a role of reducing friction and lubricating.

[0017] See image 3 . The deflection arm (6) used in the present invention has a double-ear structure, and the self-lubricating wear-resistant bushing (2) is press-fitted in the shaft hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com