Rotary drilling rig capable of being fully transported with drill pipe

A technology of rotary drilling rigs and complete machines, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high construction cost, short construction period, and limited construction site space, so as to reduce construction cost, improve construction efficiency, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

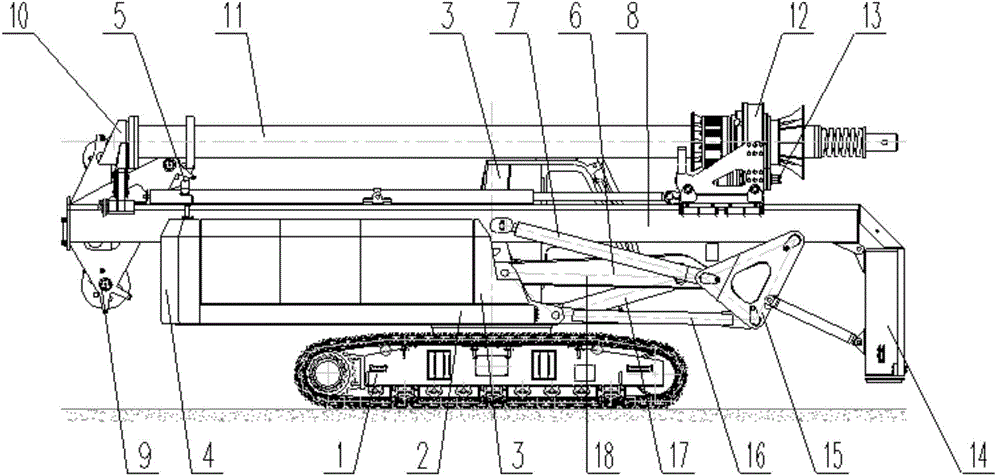

[0024] see figure 1 , the whole transport rotary drilling rig with a rod provided by the present invention includes a chassis 1, a rotary platform 2, a driver's cab 3, a counterweight 4, an electrical system 5, a luffing mechanism 6, a vertical mast cylinder 7, a mast 8, and a goose head 9 , follower frame 10, drill pipe 11, power head 12, hydraulic system 13 and lower mast 14, luffing mechanism 6 includes tripod 15, connecting rod 16, boom lifting cylinder 17 and boom 18, and the whole machine with rod is transported When the rotary drilling rig is transported, the following frame 10 is fixedly connected to the mast 8, and the drill pipe 11 is fixedly connected to the following frame 10 and the power head 12 without disassembly. In this state, it meets the requirements of road transportation and has a small turning radius.

[0025] Specifically, see figure 1 and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com