Profile angle assembling device

A technology of forming corners and profiles, applied in the direction of windows/doors, building components, walls, etc., can solve the problems of weak connection of the rear wing arm, unable to enhance the strength of the middle stile, easy deformation of the rear wing arm, etc., to ensure the corner strength. , the structure is simple, the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

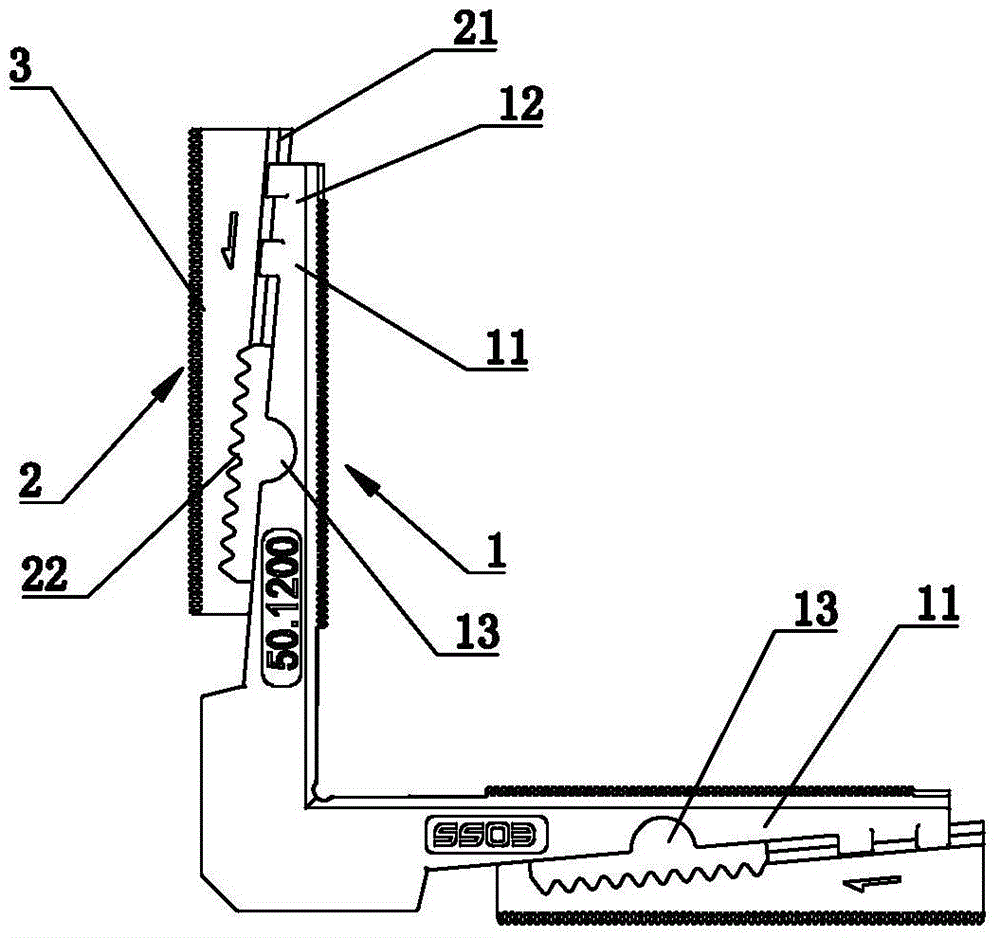

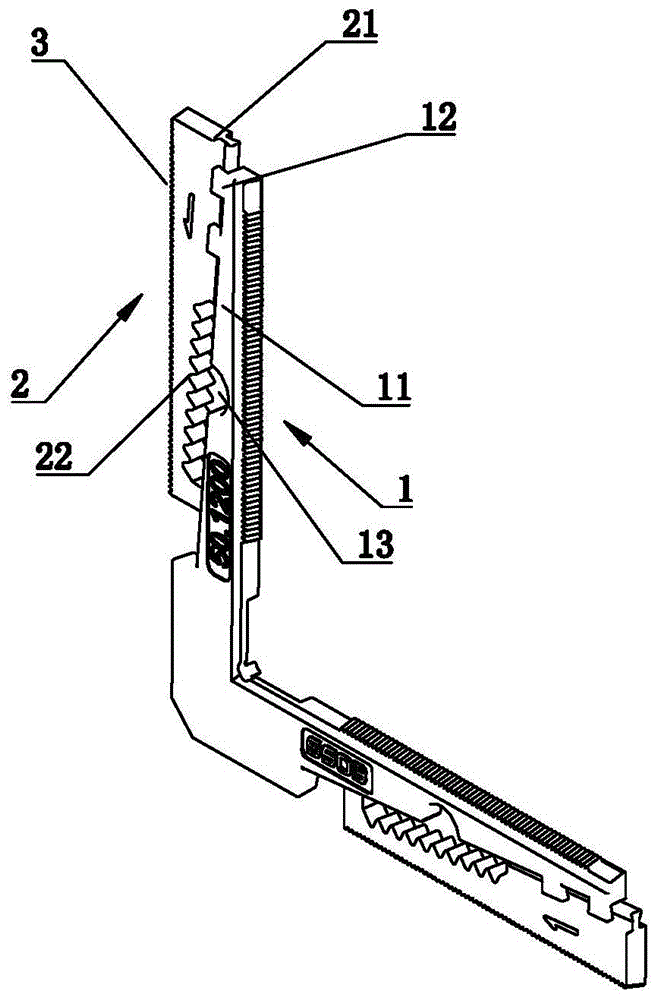

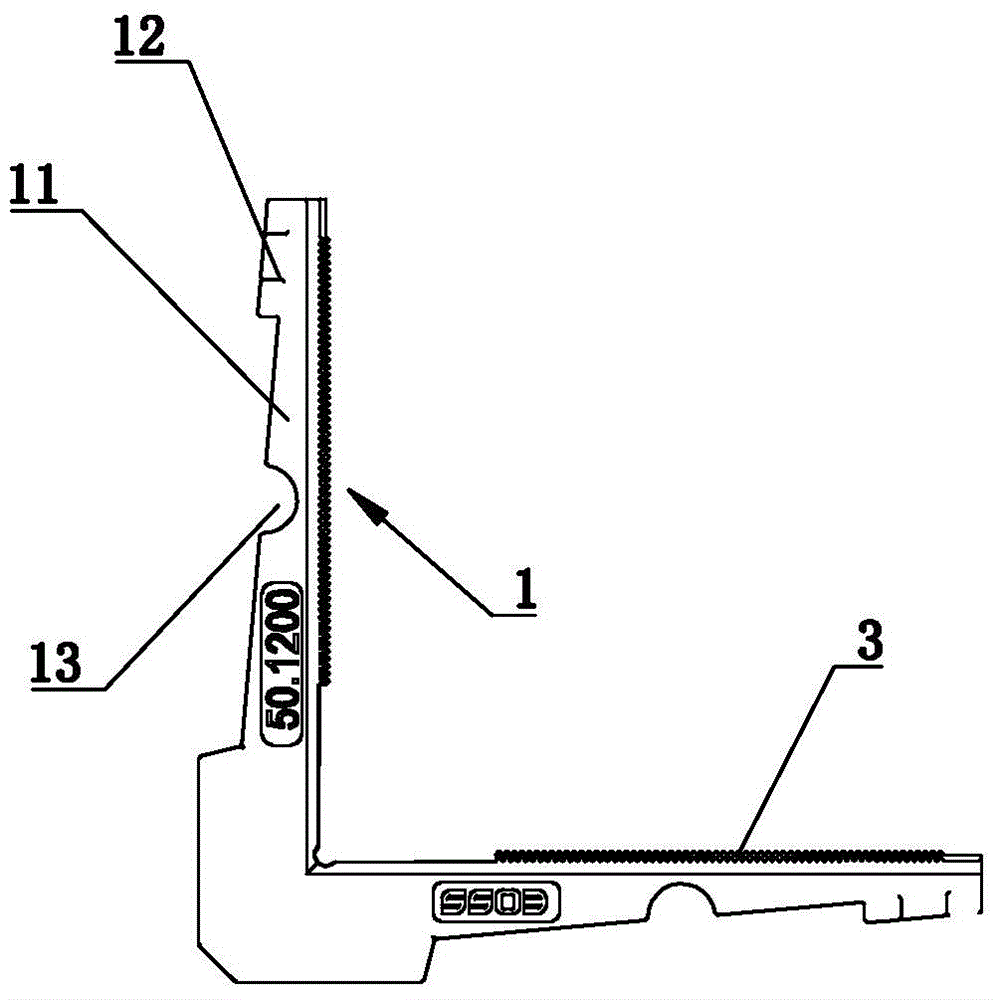

[0026] figure 1 It is a schematic structural diagram of the front view of the profile corner assembly device of the present invention; figure 2 It is a schematic diagram of the three-dimensional structure of the profile corner assembly device of the present invention; image 3 is a structural schematic diagram of the first component in the present invention; Figure 4 It is a schematic diagram of using the present invention to assemble corners.

[0027] Refer to attached figure 1 , figure 2 , image 3 as well as Figure 4 , a profile corner device, including an L-shaped first component 1, and two second components 2, the first component 1 includes two support arms 11 connected vertically to each other, defining that the two support arms 11 are far away from the vertical connection The end at is the outer end of the support arm 11, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com