Nickel-saving type gas valve alloy and preparation method thereof

A gas valve and alloy technology, which is applied in the field of nickel-saving gas valve alloy and its preparation, can solve problems such as poor processing performance, and achieve the effects of improving room temperature strength and high temperature performance, saving costs, and improving oxidation resistance.

Inactive Publication Date: 2014-11-19

CENT IRON & STEEL RES INST

View PDF12 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In short, austenitic valve steel has good high-temperature performance, poor processability and moderate cost, and is suitable for medium and high-load exhaust valves.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 700

[0024] Table 5 Comparison of 700°C tensile properties of examples of the present invention and valve alloys

[0025]

Embodiment 750

[0026] Table 6 Comparison of 750°C rotary bending fatigue performance of the examples of the present invention and valve alloys

[0027]

[0028] Table 7 Comparison of the 750°C oxidation rate of the examples of the present invention and the valve alloy

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

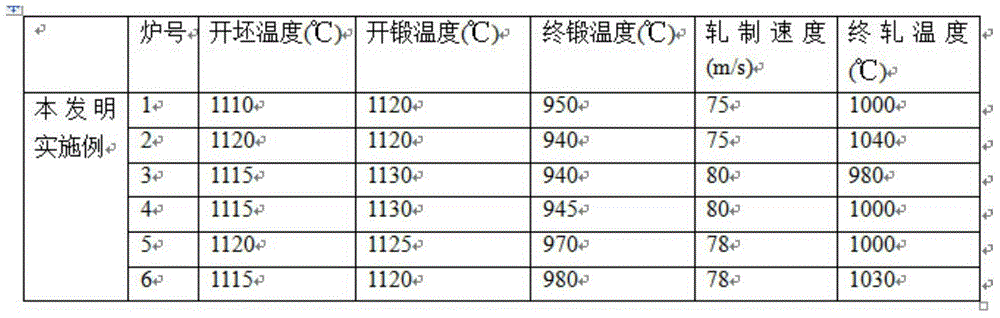

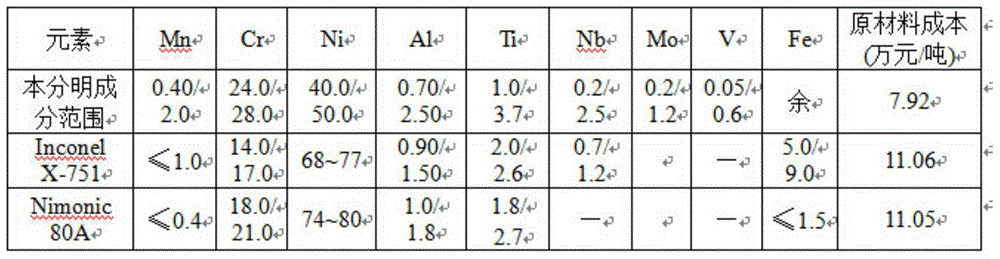

The invention relates to a nickel-saving type gas valve alloy and a preparation method thereof and belongs to the technical field of gas valve alloys. The nickel-saving type gas valve alloy comprises the following chemical components in percentage by weight: 0.01-0.30% of C, 0.10-0.50% of Si, 0.40-2.0% of Mn, not more than 0.030% of P, not more than 0.030% of S, 24.0-28.0% of Cr, 40.0-50.0% of Ni, 0.7-2.5% of Al, 1.0-3.7% of Ti, 0.2-2.5% of Nb, 0.2-1.2% of Mo, 0.05-0.5% of V and the balance of Fe and inevitable impurities. A vacuum induction furnace is adopted for smelting, an electrode is poured, a gas is adopted for protecting an electroslag furnace for electroslag re-melting and cogging and forging are performed on a steel ingot to prepare a rolled compact. The cogging temperature of the steel ingot is 1120-1140 DEG C, the forging temperature of the steel ingot is 1120-1130 DEG C, the final forging temperature is 940-980 DEG C and the square rolled compact of 140mm*140mm is forged. The rolled compact passes through a rough rolling mill, an intermediate rolling mill, a finish rolling mill and a reducing and sizing mill and enters a high-speed wire rod rolling mill. The nickel-saving type gas valve alloy has the advantages of low cost, high tensile strength, high fatigue limit and good high-temperature oxidation resistance.

Description

technical field [0001] The invention belongs to the technical field of gas valve alloys, in particular to a nickel-saving type gas valve alloy and a preparation method thereof, which are used to manufacture various intake valves and exhaust valves of internal combustion locomotives, and have high strength and good economy. Background technique [0002] Gas valve steel and gas valve alloy are important materials for manufacturing gas valves, and gas valves are essential parts in internal combustion engines such as gasoline engines, diesel engines, compressed natural gas engines, liquefied petroleum gas engines and dual-fuel engines. Under the high temperature generated by the combustion of medium oil and gas mixture, at the same time, it is under the scouring of the corrosive medium produced by insufficient oil combustion, and it must also work under long-term cyclic loads. Therefore, the valve steel and valve alloy must not only have High high temperature strength and hardne...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C19/05C22C1/02

Inventor 王立民杨钢刘正东包汉生赵吉庆何西扣

Owner CENT IRON & STEEL RES INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com