Processing method for yak shoe upper leather

A processing method and technology of yak leather, which is applied in the field of processing yak leather upper leather, can solve the problems of weak connection and less fiber, and achieve the effect of good extensibility, good napping and clear grain surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

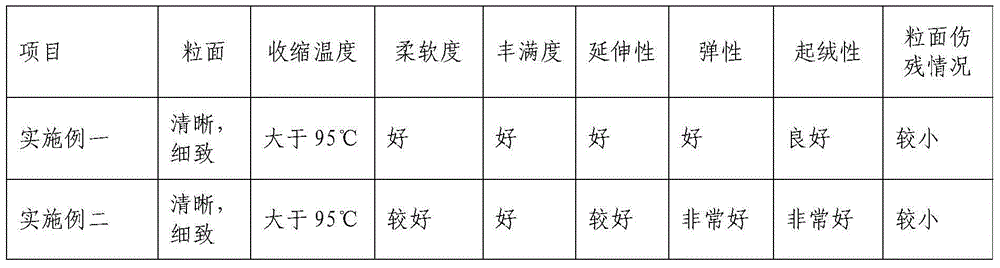

Examples

Embodiment 1

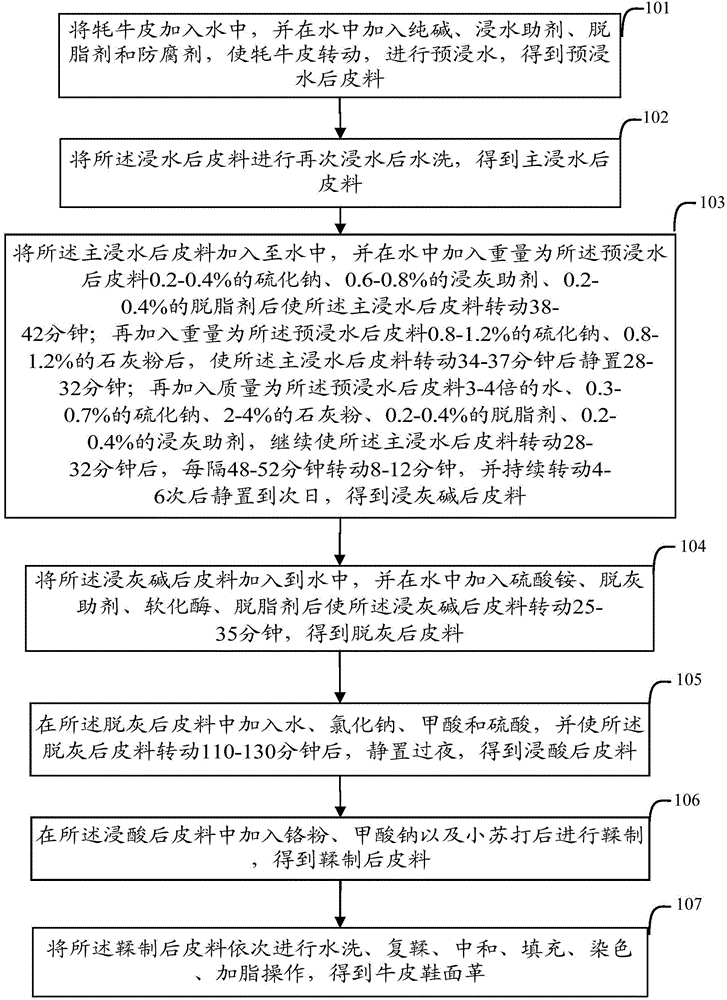

[0035] The processing method of this yak leather upper leather that the embodiment of the present invention provides, please refer to figure 1 , including the following steps:

[0036] Step 101: Adding yak hide to water, adding soda ash, soaking aid, degreasing agent and preservative to the water, rotating the yak hide and pre-soaking water to obtain the pre-soaked leather material;

[0037] In step 101, after pre-soaking, all dirt, impurities and soluble protein on the yak hide can be removed (by soda ash, soaking aid, degreasing agent and preservative), and the floating meat and oil film on the hide can also be removed. Most of it is removed in the water immersion operation, so that the skin collagen fiber structure of the yak hide is loose and filled with water, which is beneficial to the subsequent operation. At this time, the skin material after pre-soaking in water can be removed and weighed, so that it is convenient to add a predetermined weight in the subsequent operat...

Embodiment 2

[0063] In the present embodiment, the preparation method of the processing method of yak leather shoe upper leather comprises the following steps:

[0064] S1: adding yak hide to water 3-4 times its weight, and adding 0.8-1.2% of soda ash by weight to the water to rotate the yak hide;

[0065] S2: Add the yak hide, 0.3-0.7% soaking aid, 0.2-0.4% degreaser and 0.1% antiseptic into the water after turning for 18-22 minutes, and continue to turn the yak hide for 4 After -5 hours, let it stand until the next day to obtain the leather material after pre-soaking water;

[0066] S3: Add the pre-soaked leather into water 3-4 times its weight, and add 0.8-1.2% of the weight of the pre-soaked leather into the water, and then rotate the pre-soaked leather ;

[0067] S4: After rotating for 18-22 minutes, add 0.8-1.2% water soaking aid, 0.2-0.4% degreaser and 0.1% preservative to the water after the pre-soaked leather, and continue to make the yak skin After turning for 4-5 hours, let i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com