A sludge fluidized bed drying device

A sludge fluidized bed, fluidized bed technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the wear of the heating surface of the fluidized bed dryer , failure rate increase, consumption of river sand and other problems, to achieve the effect of improving the quality of dried sludge, avoiding agglomeration, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment.

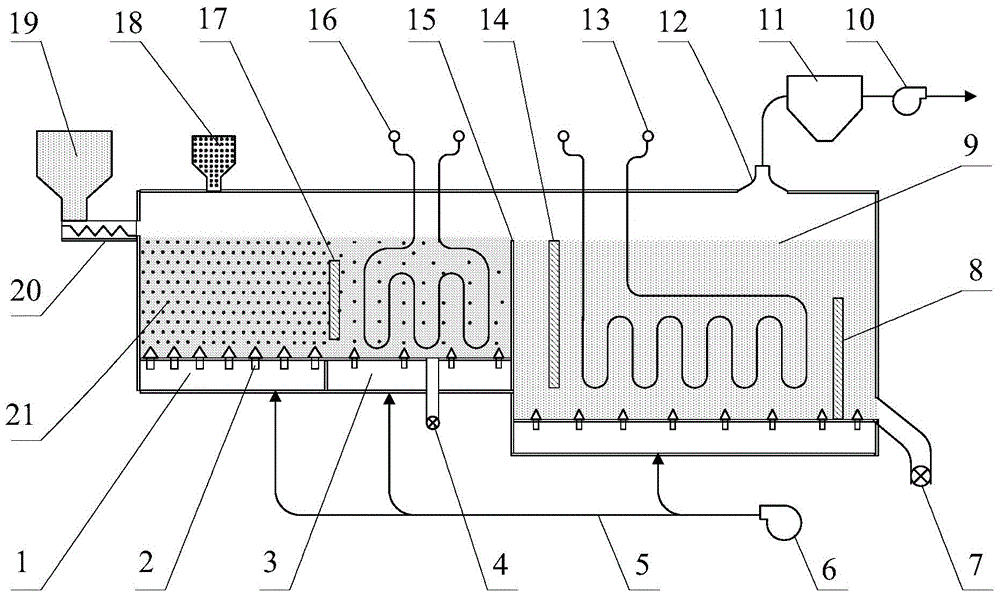

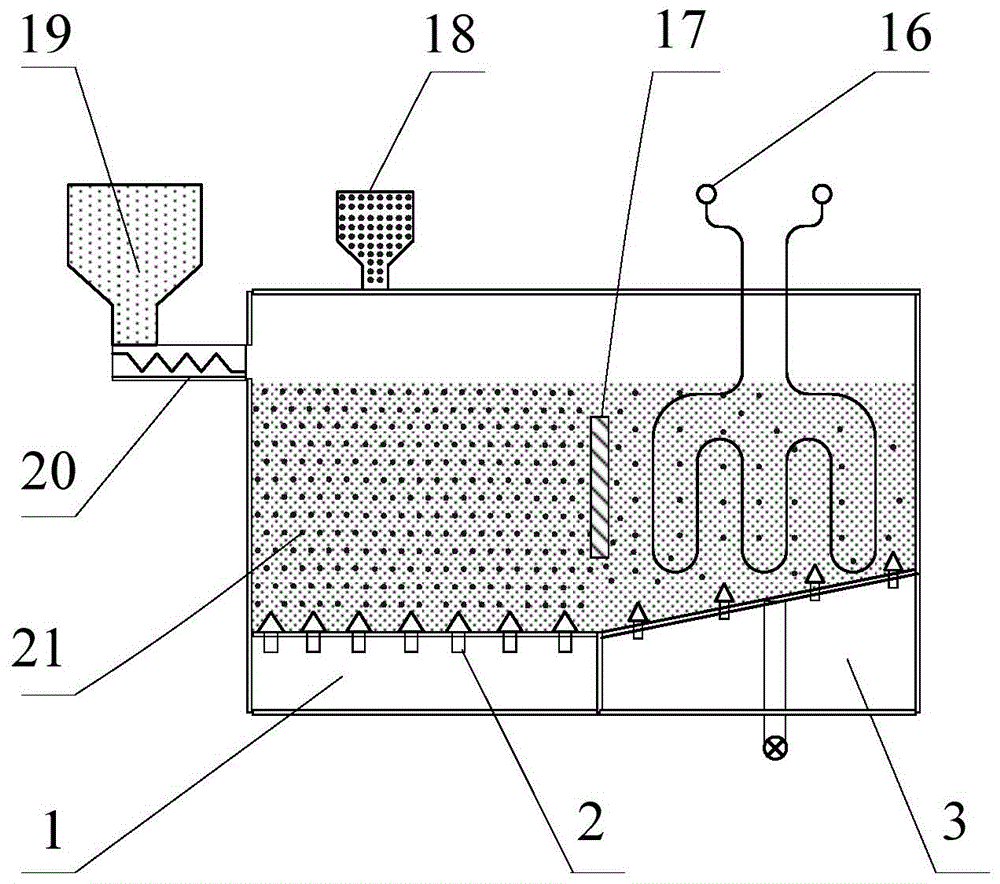

[0031] see figure 1 , the technical scheme that the present invention adopts is: comprise grinding bed 1, return material bed 3 and drying bed 9 that are connected in sequence, intermediate partition 17 is set between grinding bed 1 and return material bed 3, intermediate partition The upper and lower parts of 17 are provided with passages to communicate with the return material bed 3, a partition plate 15 is provided between the return material bed 3 and the drying bed 9, and the upper part of the separation plate 15 is provided with channels to communicate with the drying bed 9 , the depths of the grinding bed 1 and the return bed 3 are all less than the depth of the drying bed 9;

[0032] The grinding bed 1 is provided with a sludge inlet and an abrasive inlet. The sludge inlet of the grinding bed 1 is connected to the sludge hopper 19 through the mud feeder 20 , and the abrasive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com