Wheel edge motor power coupling transmission system of four-wheel driving vehicle

A wheel-side motor and transmission system technology, applied in the direction of power plant, vehicle components, motion deposition, etc., can solve the problems of large power demand of wheel hub motors, loss of adhesion performance of wheels, idle power of wheel-side motors, etc., to improve power utilization Speed and acceleration performance, eliminating the need for inter-wheel differential locking mechanism, ensuring the effect of movement coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

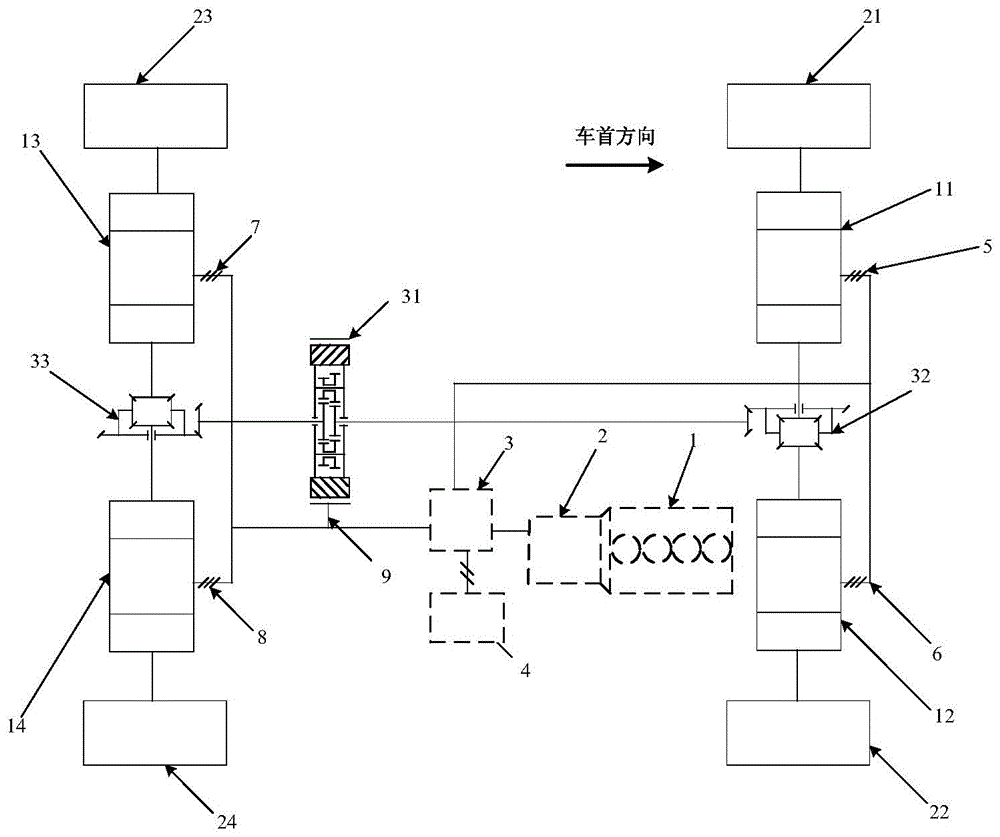

[0020] See attached figure 1 , 4×4 vehicle wheel side motor power coupling transmission system, its specific composition is as follows:

[0021] The front transmission chain part composed of engine 1, generator 2, motor and generator controller 3, and power battery pack 4 can be flexibly placed in the interior space of the vehicle; among them, engine 1 is connected to generator 2, and generator 2 is connected to motor and the generator controller 3 are connected, and the motor and the generator controller 3 are connected with the power battery pack 4;

[0022] The front axle two wheel motors and their reduction gears 11, 12 respectively drive the wheels 21, 22 on both sides of the front axle, and the front axle differential 32 couples the power of the front axle two wheel motors and their reduction gears 11, 12;

[0023] The two wheel side motors of the rear axle and their reduction gears 13, 14 respectively drive the wheels 23, 24 on both sides of the rear axle, and the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com