Anti-explosion lining of automobile tire

A technology for automobile tires and inner linings, applied in tire parts, vehicle parts, transportation and packaging, etc., can solve the problem of difficulty in popularizing puncture-resistant tires, and achieve the effect of reducing the probability of car accidents, simple structure, and favorable popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is a special soft protective ring pad between the outer tire 4 and the inner tire 1 of an automobile.

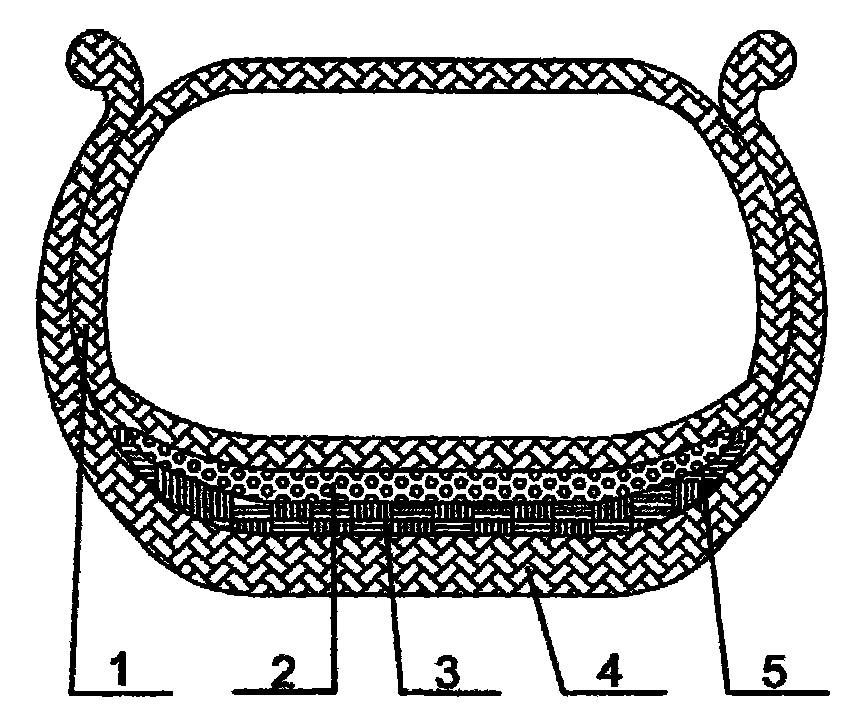

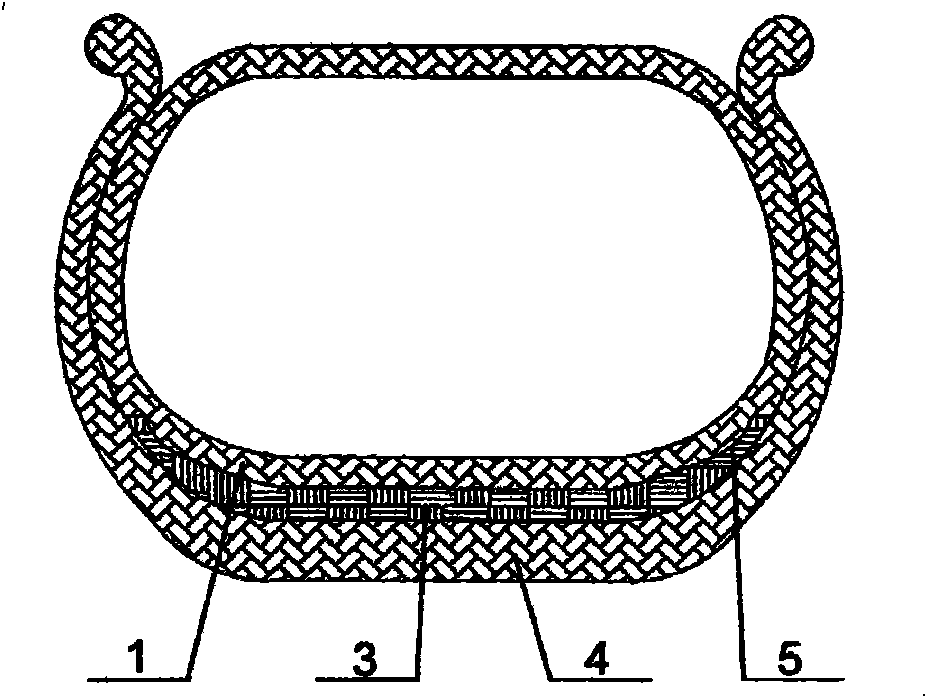

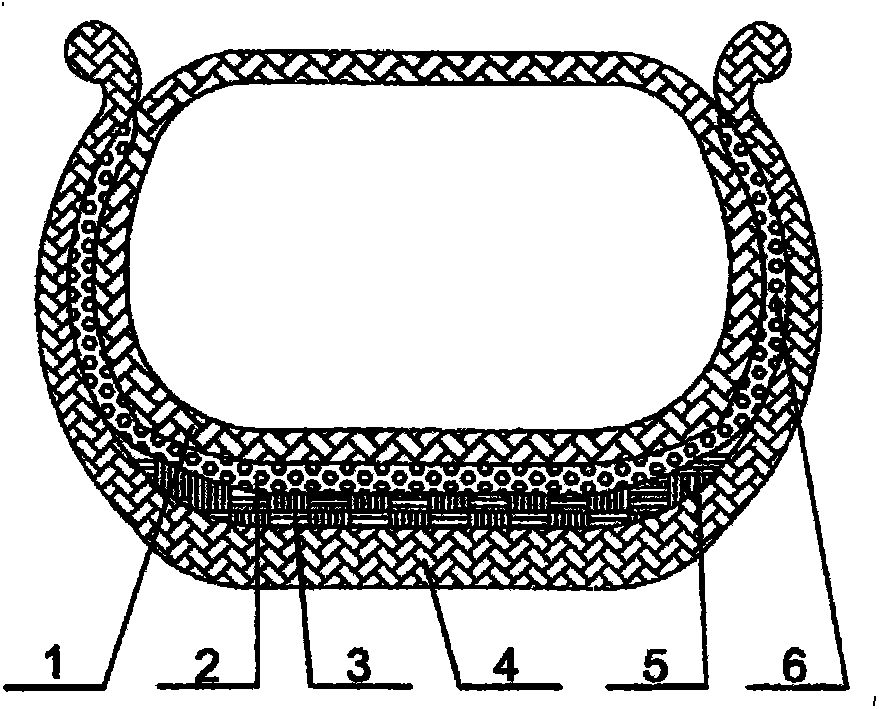

[0016] figure 1 As shown, when the protective ring is composed of two parts, a stab-proof layer 3 and a heat-insulating layer 2, it exhibits two characteristics of "stab-proof" and "heat-insulation"; figure 2 As shown, when the protective ring has only the stab-resistant layer 3, it exhibits the characteristic of "stab-resistant"; image 3 As shown, when the two sides of the heat insulation layer extend 6 toward the center of the tire and wrap the tire inner tube, the heat insulation effect can be increased. Both sides of the edge of the protective ring contract 5 inwardly, and the shape is consistent with the inner surface of the outer tire, so that the explosion-proof inner lining of the automobile tire and the inner / outer tire of the automobile are closely attached to facilitate the assembly of the tire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com