Pen withdrawal trigger mechanism of electric pencil sharpener

A trigger mechanism and pencil sharpening technology, which is applied in the mechanical field, can solve the problems of electric pencil sharpener function influence, micro switch sensitivity reduction, and no automatic pen retracting function, so as to achieve high sensitivity, fast response time, and avoid being affected damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

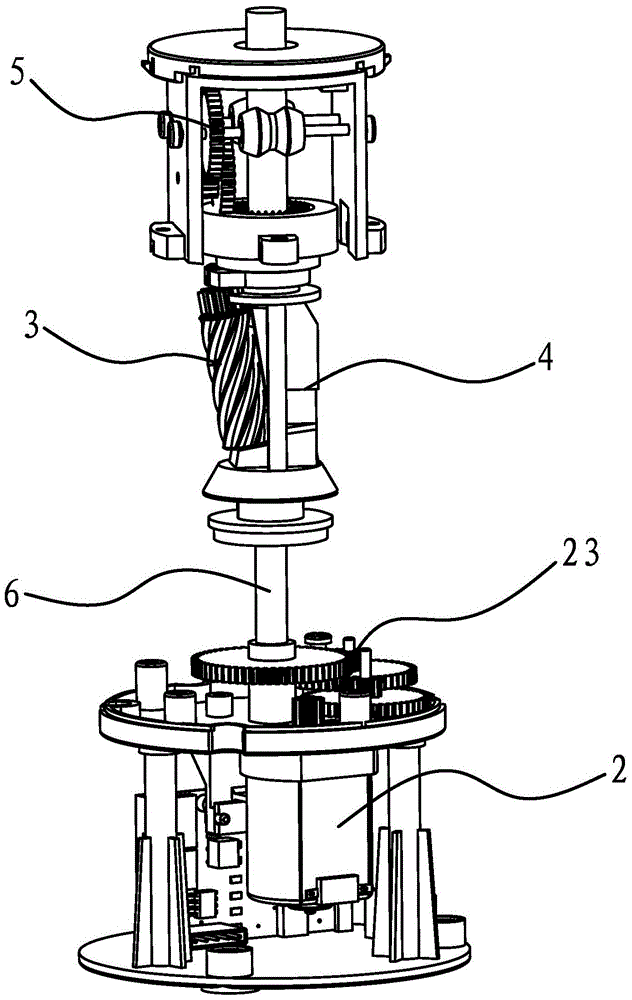

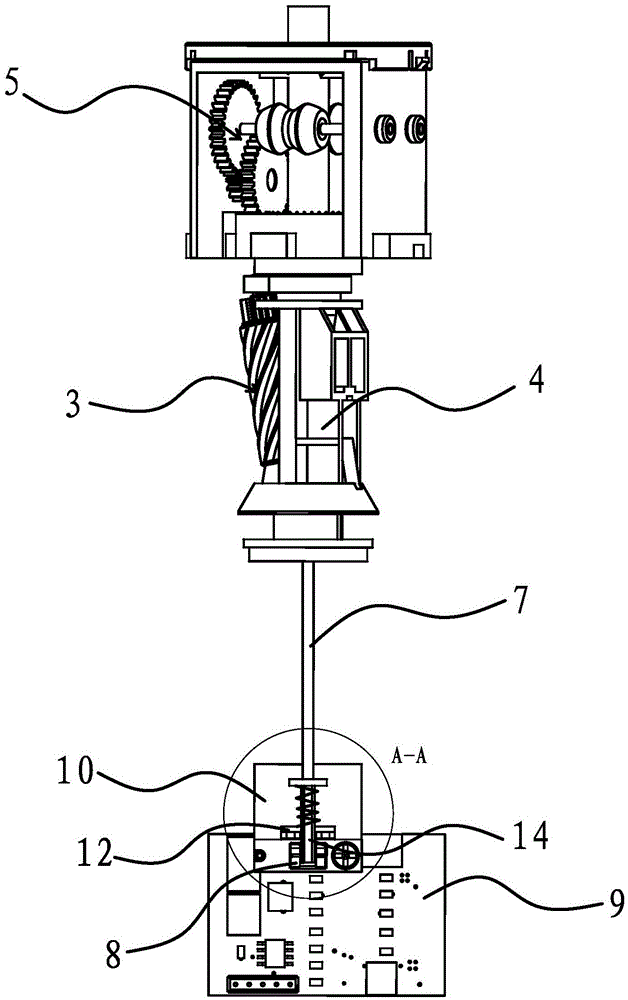

[0040] like figure 1 and Figure 8 As shown, a pen withdrawal trigger mechanism of an electric pencil sharpener is arranged in the casing 1 of the electric pencil sharpener. The casing 1 of the electric pencil sharpener is cylindrical, the bottom of the casing 1 is provided with a power interface 24, the casing 1 is provided with a motor 2, a pen holder 4 connected with a planing assembly 3 and a pen feeding assembly 5, and a motor 2 A drive shaft 6 is arranged between the pen holder 4, and a transmission gear set 23 is arranged between the output shaft of the motor 2 and the transmission shaft 6. When the motor 2 rotates, the drive shaft 6 can be driven to rotate by the transmission gear set 23, and the pen holder 4 rotates. Afterwards, the pen feeding assembly 5 can be driven into the pen and the planing assembly 3 can be driven to plan the pencil.

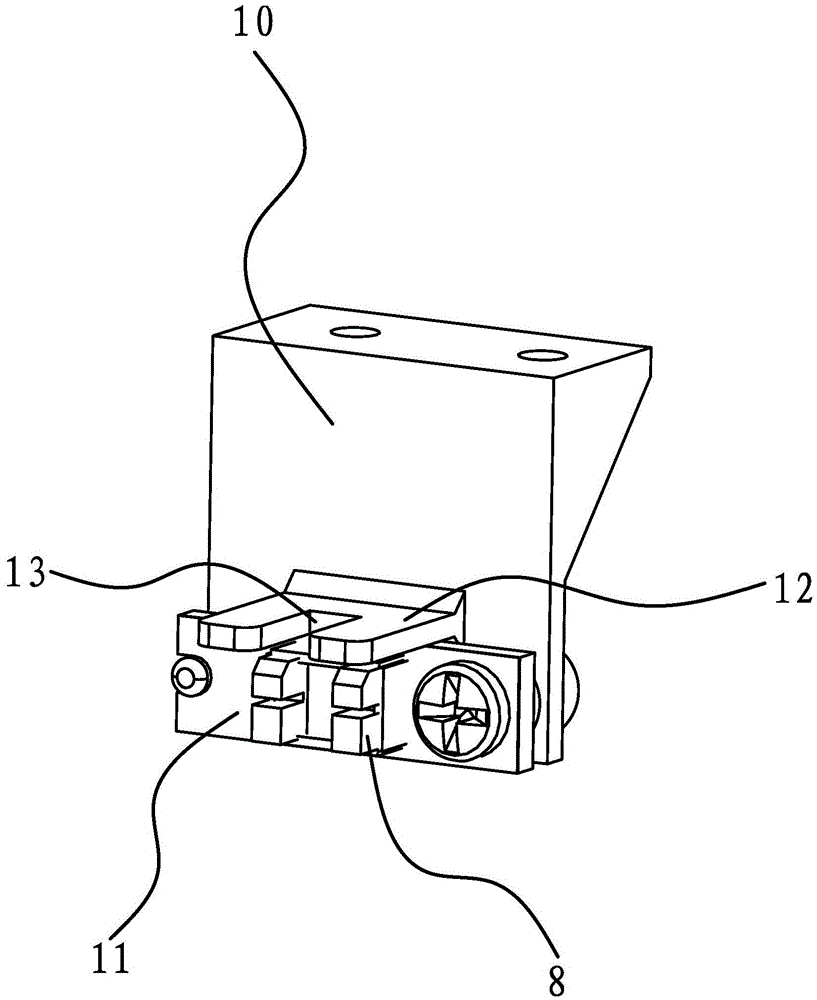

[0041] like figure 2 As shown, the triggering mechanism for retracting the pen includes the ejector rod 7 arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com