Multi-piece-glass overall injection molding assembly

A technology of integral injection molding and sheet glass, applied in the direction of coating, etc., can solve the problems such as the diversified needs of customers for diversified shapes and functions, and the inability of automobile edging glass assembly to achieve the effect of improving the degree of freedom and eliminating the single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

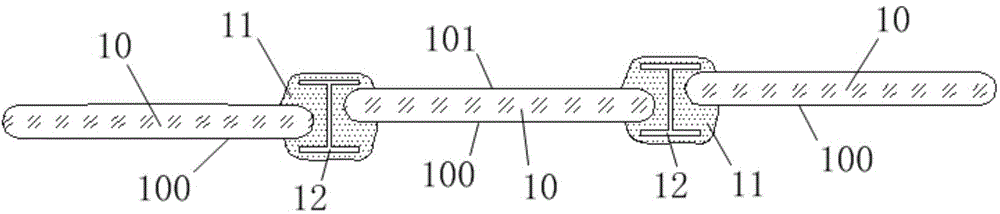

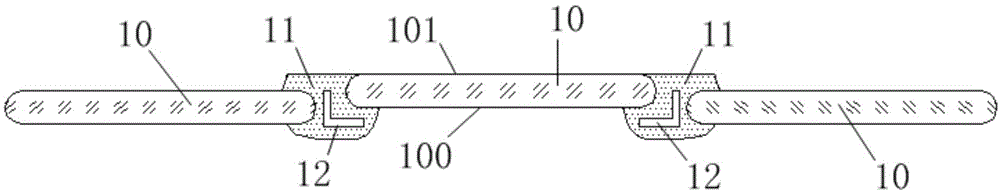

[0024] like figure 1 As shown, the multi-piece glass integral injection molding assembly of the present invention includes at least two pieces of glass 10, and is characterized in that it also includes an injection molding part 11, and the injection molding part 11 is integrally injection molded between two adjacent pieces of glass 10 The lower part of the injection molding part 11 is covered and fixed on the inner surfaces 100 of the two adjacent edges of the two pieces of glass 10 . In this way, multiple pieces of glass 10 and the injection molding part 11 can be integrated into a whole through the injection molding part 11 of integral injection molding, and multiple pieces of glass with different characteristics can be integrally compounded and injected, eliminating the single color, single strength and surface structure. The shortcomings such as singleness meet the needs of customers with diverse shapes or functions. In the present invention, for the sake of simplicity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com