Shaping die for manufacture of gas turbine seals and manufacture process of gas turbine seals

A technology of machine sealing sheet and production process, applied in the field of machining, can solve problems such as equipment failure, no production precedent, no mold and production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

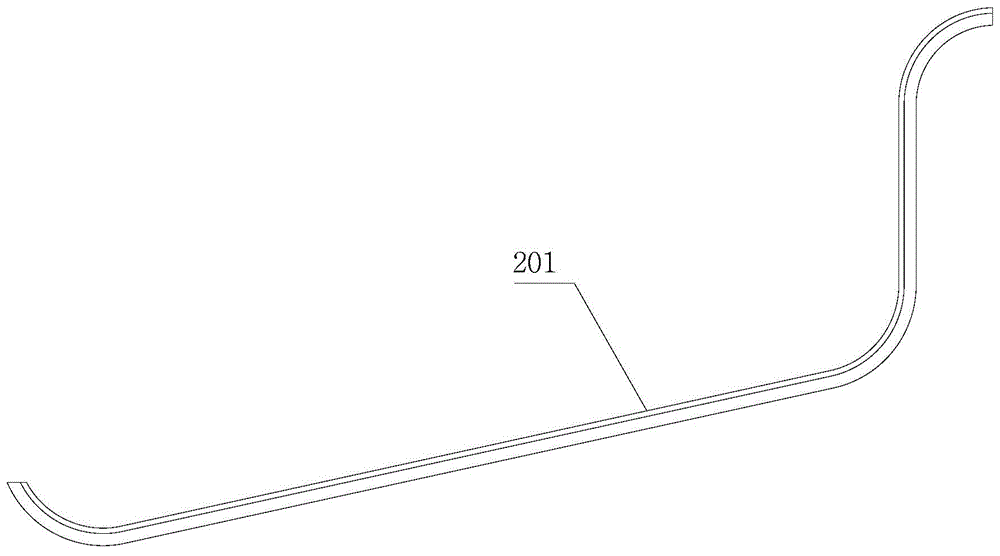

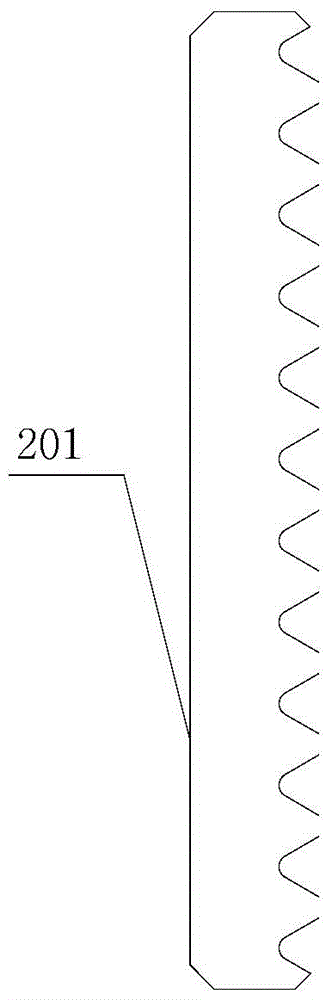

[0057] Developed countries in Europe and the United States have realized gas turbine power generation as early as 40-50 years ago. my country has only introduced, absorbed, and localized gas turbines in this field for about ten years. At present, the localization rate of gas turbines in my country has reached 90%, and the localization of some key components is still a bottleneck problem, which requires us to achieve breakthroughs in this field. At present, all the work done on the axial seal of the gas turbine impeller (referred to as the seal) is the first development and research in China. At present, there is no similar production mold and process flow in the domestic market. There are many kinds of sealing sheets in the gas turbine, and the present invention is only aimed at one of them ( Figure 1-Figure 3 Shown) the sealing sheet is illustrated, the gas turbine sealing sheet manufacturing process provided by the present invention is applicable to all sealing sheets in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com