Dental handpiece oiling and cleaning system and oiling and cleaning method thereof

A technique for dental handpieces and cleaning systems, applied in cleaning methods and appliances, chemical instruments and methods, mechanical equipment, etc., can solve the problems of unacceptable manual cleaning of handpieces, large waste of cleaning agents and lubricating oil, uneven oil injection, etc., to achieve Prevent accumulated water from entering the interior of the mobile phone, facilitate oil filling, and achieve reliable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

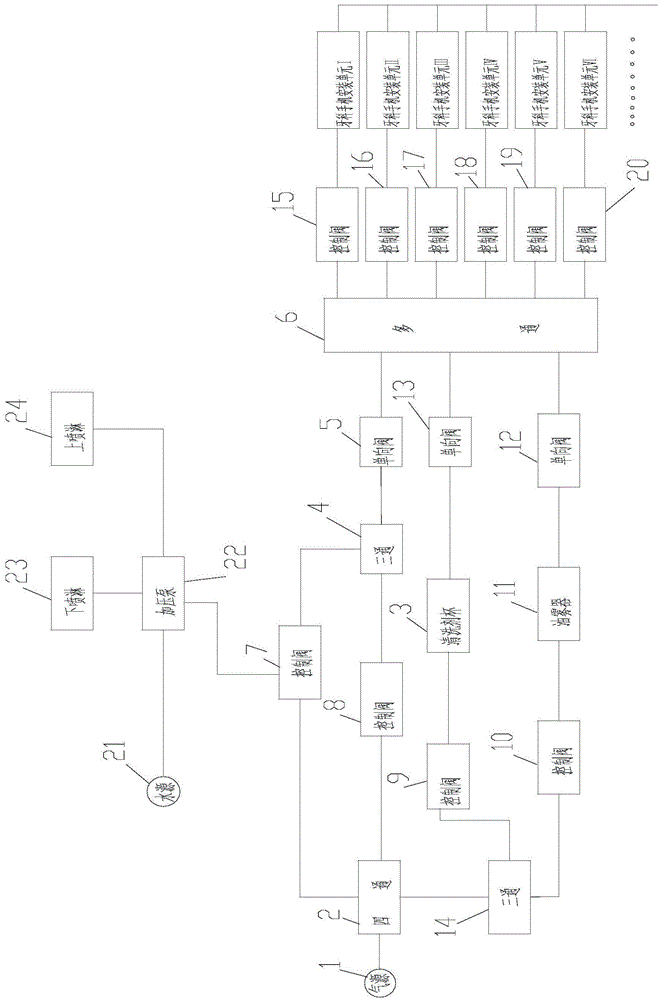

[0016] Attached below figure 1 An embodiment of the present invention is described.

[0017] The dental handpiece oiling cleaning system has a four-way 2, a three-way 14 and a nine-way 6, the output end of the air source 1 is connected to the input end of the four-way 2, the first output end of the four-way 2 is connected to the input end of the three-way I14, and the three-way The first output end of the channel I14 is connected to the input end of the detergent cup 3 through the control valve I9, and the output end of the detergent cup 3 is connected to the first input end of the nine-way channel 6 through the one-way valve I13; the second output end of the three-way I14 is passed through The control valve II10 is connected to the input end of the lubricator 11, and the output end of the lubricator 11 is connected to the second input end of the nine-way 6 through the one-way valve II12; the second output end of the four-way 2 is connected to the three-way II4 through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com