Gypsum crystallization regulator suitable for wet type calcium-based flue gas desulphurization poisoning slurry

A technology of crystallization regulator and gypsum, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as decline, waste of resources, device reliability, etc., and achieve the effect of increasing stability and ensuring utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

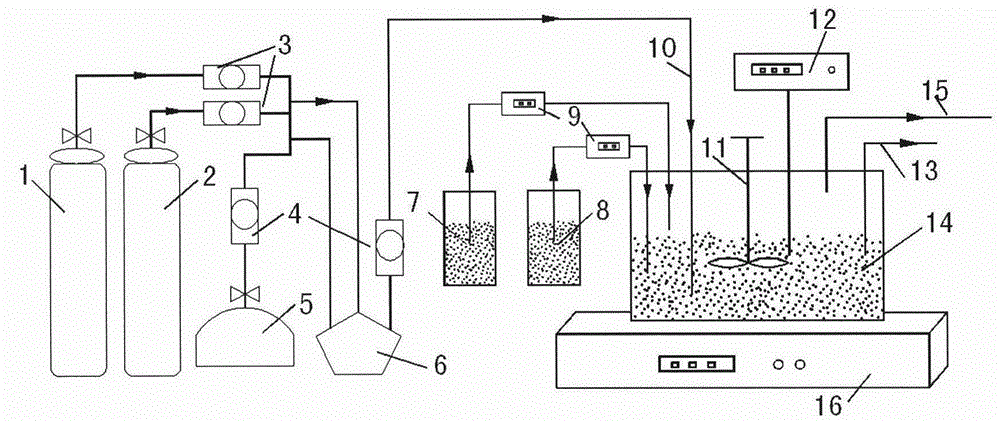

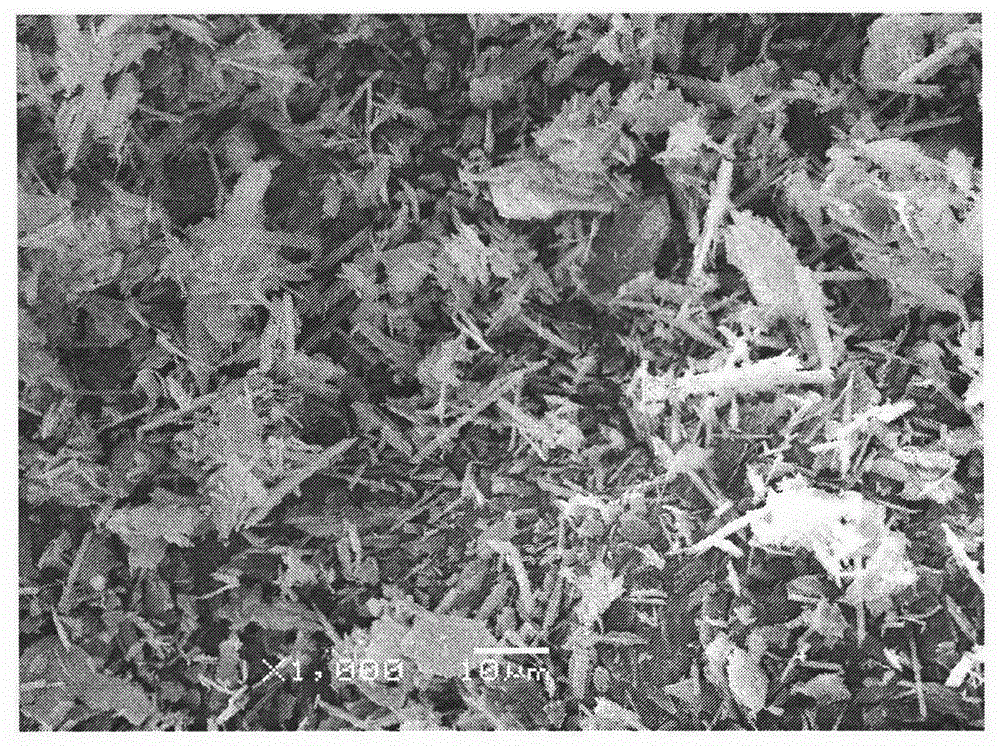

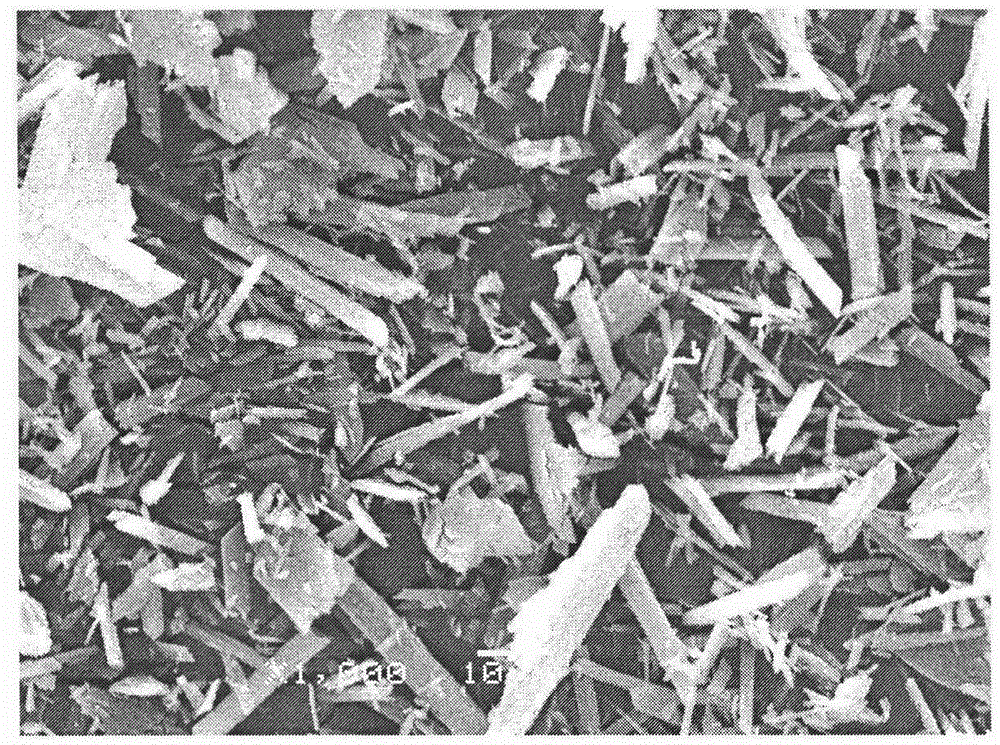

[0026] According to the above process (see attached manual figure 1), to simulate the preparation of flue gas at the tail of a thermal power plant boiler, the mass flow rate of flue gas is 8kg / h (volume flow rate 6.31Nm 3 / h), O in flue gas 2 Volume content 10%, N 2 The volume content is 89.9%, SO 2 The content is 1000mg / m 3 , The constant temperature temperature controller stabilizes the temperature of the slurry in the reactor at about 40°C, and the stirring rate is 100r / min. With the limestone that purity is 98.5% as desulfurizer, its mass percent concentration is 2.5%, and initial slurry volume is 4L, and concentration is the greasy dirt of 1000mg / L, the heavy gold ion salt solution of 0.15mol / L (Fe 3+ , Mg 2+ 、Al 3+ ) is pumped into the reactor by a peristaltic pump, so that the volume of the slurry in the reactor is increased to 5L. After mixing evenly, the oil pollution concentration in the reactor is 200mg / L, and the heavy gold ion concentration is 0.03mol / L (Fe...

Embodiment 2

[0028] According to the flow process of embodiment 1, the flue gas at the tail of a certain thermal power plant boiler is simulated and prepared, and the flue gas mass flow rate is 8kg / h (volume flow rate 6.31Nm 3 / h), O in flue gas 2 Volume content 10%, N 2 The volume content is 89.9%, SO 2 The content is 1000mg / m 3 , The constant temperature temperature controller stabilizes the temperature of the slurry in the reactor at about 40°C, and the stirring rate is 100r / min. With the limestone that purity is 98.5% as desulfurizer, its mass percent concentration is 2.5%, and initial slurry volume is 4L, and concentration is the greasy dirt of 1000mg / L, the heavy gold ion salt solution of 0.15mol / L (Fe 3+ , Mg 2+ 、Al 3+ ) is pumped into the reactor by a peristaltic pump, so that the volume of the slurry in the reactor is increased to 5L. After mixing evenly, the oil pollution concentration in the reactor is 200mg / L, and the heavy gold ion concentration is 0.03mol / L (Fe 3+ , Mg...

Embodiment 3

[0030] According to the flow process of embodiment 1, the flue gas at the tail of a certain thermal power plant boiler is simulated and prepared, and the flue gas mass flow rate is 8kg / h (volume flow rate 6.31Nm 3 / h), O in flue gas 2 Volume content 10%, N 2 The volume content is 89.9%, SO 2 The content is 1000mg / m 3 , The constant temperature temperature controller stabilizes the temperature of the slurry in the reactor at about 40°C, and the stirring rate is 100r / min. With the limestone that purity is 98.5% as desulfurizer, its mass percent concentration is 2.5%, and initial slurry volume is 4L, and concentration is the greasy dirt of 1000mg / L, the heavy gold ion salt solution of 0.15mol / L (Fe 3+ , Mg 2+ 、Al 3+ ) is pumped into the reactor by a peristaltic pump, so that the volume of the slurry in the reactor is increased to 5L. After mixing evenly, the oil pollution concentration in the reactor is 200mg / L, and the heavy gold ion concentration is 0.03mol / L (Fe 3+ , Mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com