Integrated separated-seamless-suspension-type loose-leaf bulk curing device

A baking device and hanging technology, which is applied in the field of integrated separation and seamless hanging loose leaf baking device, can solve the problems of easy rolling, large volume of leaf loading frame and solid leaf hanging rack, troublesome use, etc., and achieve easy Mastery, easy to operate, reduce mechanical damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

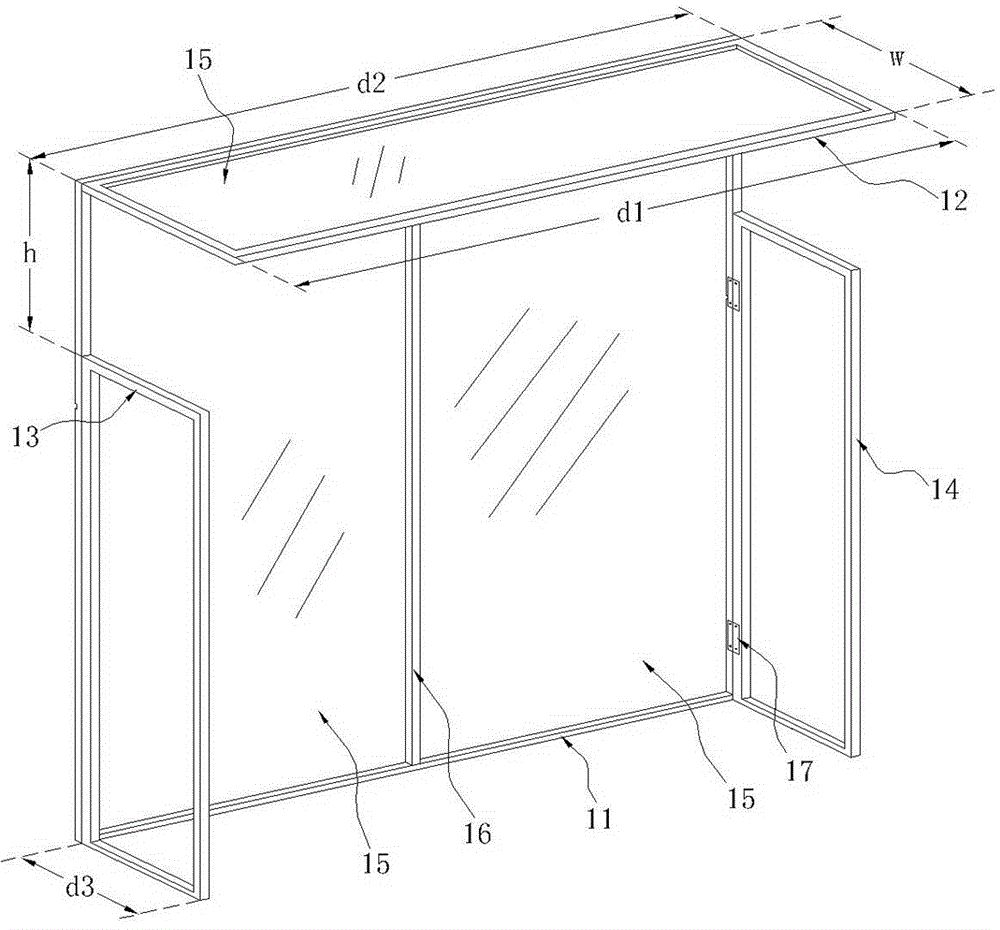

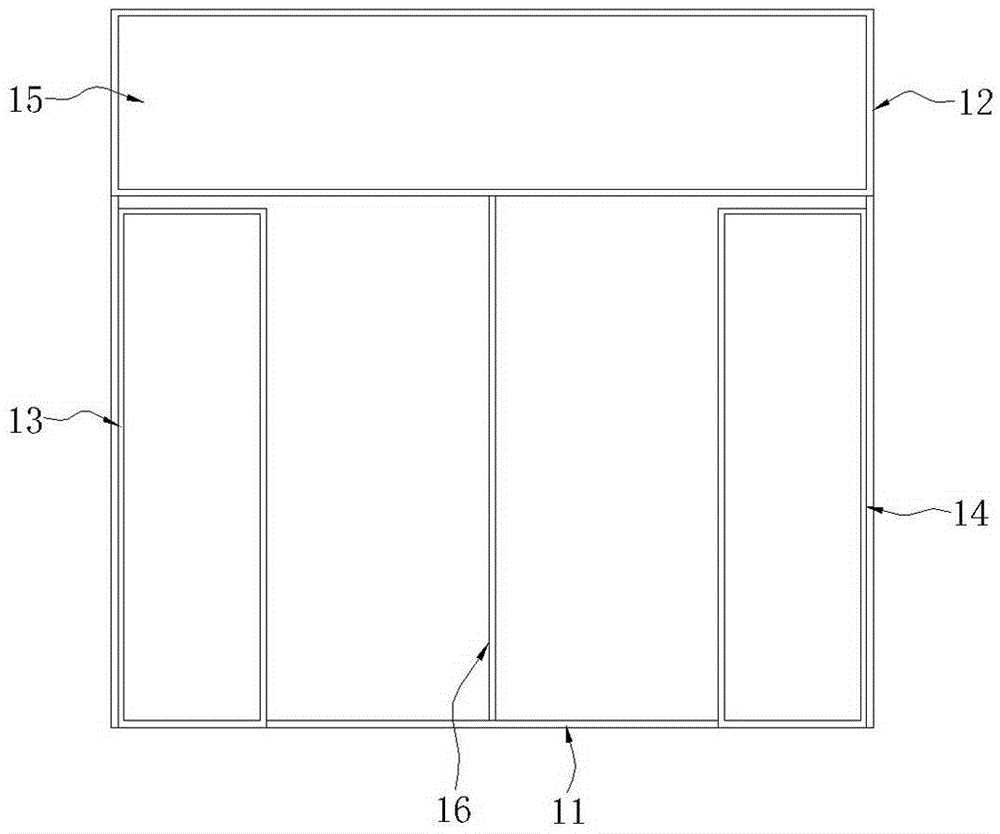

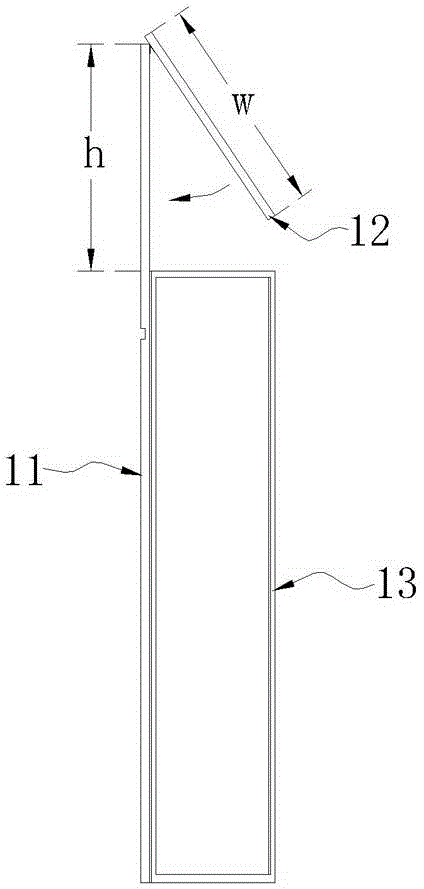

[0047] like Figure 1~3 As shown, the baking rack includes a rectangular main frame 11, an upper baffle frame 12, a left baffle frame 13 and a right baffle frame 14, and the upper baffle frame 12 is vertically connected to the upper edge of the main frame 11, and the left baffle frame The plate frame 13 is vertically connected to the left edge of the main frame 11, and the right baffle frame 14 is vertically connected to the right edge of the main frame 11. The left baffle frame 13 and the right baffle frame 14 are arranged symmetrically so that the upper edges are flush, so as to ensure that the smoke penetrating rod can be placed horizontally, and the upper edges of the left baffle frame 13 and the right baffle frame 14 are aligned with the upper edge of the main frame 11. (It is flush with the upper baffle frame 12) There is a space with a height of h to place the smoke hanging rod.

[0048] Considering the convenience of transportation and storage, the upper baffle frame ...

Embodiment 2

[0055] like Figure 4~8 As shown, the smoke penetrating rod includes a rectangular smoke penetrating frame surrounded by the left cross bar 21, the upper cross bar 22, the right cross bar 23 and the lower cross bar 24, and the upper cross bar 22 and the lower cross bar 24 are respectively provided with vertical The upper row of leaf piercing needles 25 and the lower row of leaf piercing needles 26 on the plane where the tobacco threading frame is located, and the upper row of leaf piercing needles 25 and the lower row of leaf piercing needles 26 are located on the upper side of the frame. The upper row of leaf-piercing needles 25 and the lower row of leaf-piercing needles 26 can rotate in opposite directions on the upper cross bar 22 and the lower cross bar 24 respectively, so that the cigarette-piercing hanging rod can be folded and stored when not in use. Can not injure the operator, the pinhead of the upper row of leaf piercing needles 25 and the lower row of leaf piercing ...

Embodiment 3

[0061] like Figure 9~12 As shown, the difference between this embodiment and Embodiment 2 is that the two ends of the upper cross bar 22 passing through the left cross bar 21 and the right cross bar 23 are provided with balance plates 27 parallel to the upper row of needles 25 . Since the balance plate 27, the upper row of needles 25, and the lower row of needles 26 are parallel to each other, when the tobacco hanging rod is placed on the main beam of the flue-cured room or the rack for curing tobacco, it is located at the two ends of the upper cross bar 24. The balance plate 27 is in a horizontal state, so that the upper row of leaf piercing needles 25 and the lower row of leaf piercing needles 26 can always be in a horizontal state, and the punctured tobacco leaves can also be kept vertically downward for roasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com