Fixing devices for rear bench seats of motor vehicles

A technology for motor vehicles and fixing devices, applied in vehicle seats, special positions of vehicles, vehicle components, etc., can solve the problems of ISOFIX fixed point displacement exceeding the maximum allowable displacement, wire deformation, etc., and achieve good mechanical resistance and production cost. favorable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

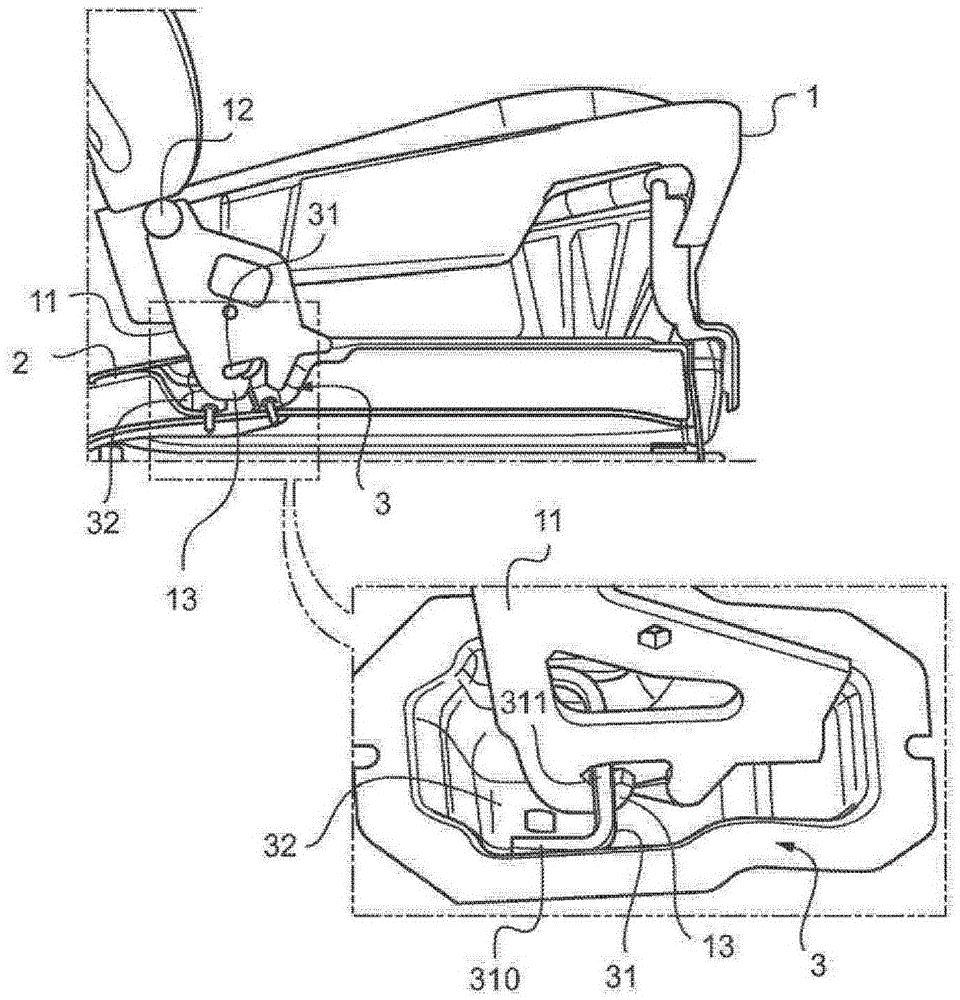

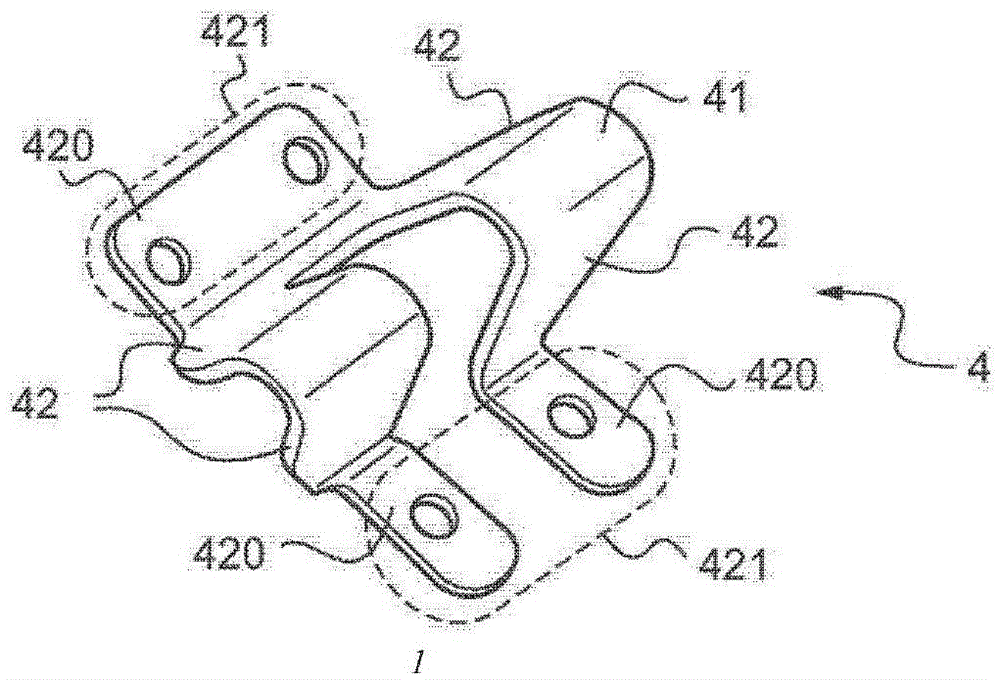

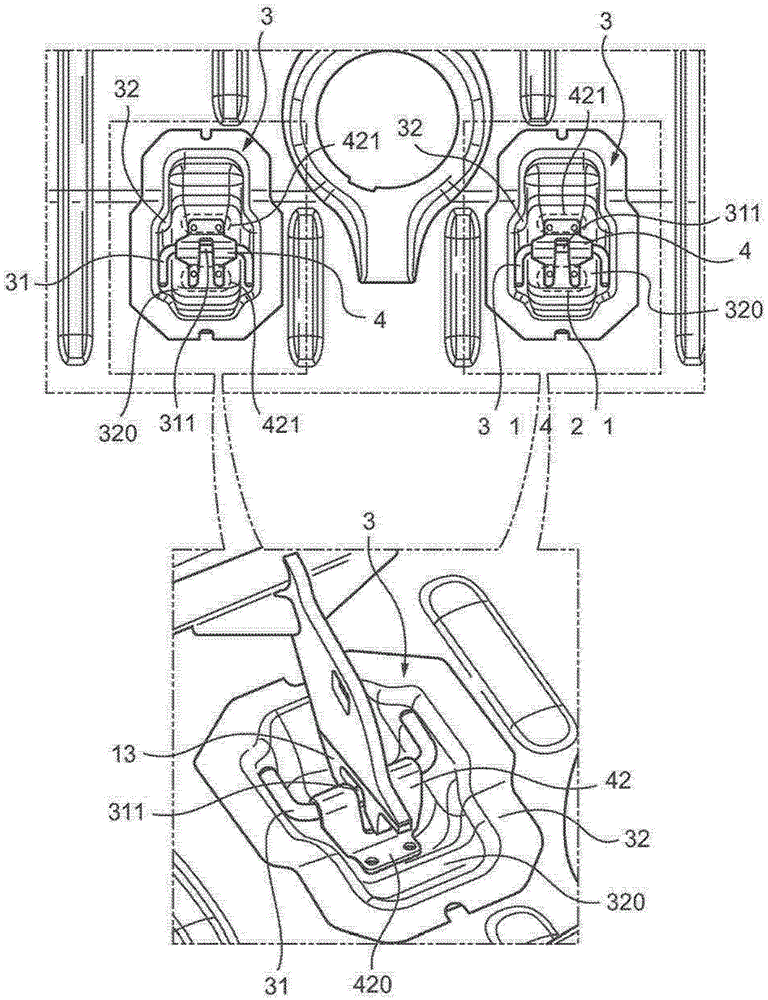

[0015] figure 1 A rear bench seat 1 of a motor vehicle is shown, for example a second row bench seat mounted on the floor 2 of the motor vehicle. For this purpose, the bench seat 1 conventionally comprises two rear fastening plates 11 fixedly mounted on a cross member 12 arranged in the lower part of the back of the bench seat, for example substantially between the seat base and the backrest of the bench seat. connection point between. Each fixing plate 11 is made of metallic material and is shaped in its lower part to form a catch member 13 intended to cooperate with the anchor member 3 fixedly mounted on the floor 2 . This anchoring member 3 conventionally takes the form of a wire 31 in which the catch member 13 carried by the rear fixing plate 11 engages to fix the bench 1 to the floor 2 . In order to allow this capture, the wire 31 of the anchoring member 3 is fixed transversely in a cavity 32 formed in the floor and extending along the longitudinal axis of the motor veh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap