Standard fastener visual detection mechanism

A standard fastener and visual inspection technology, applied in the direction of measuring devices, optical testing defects/defects, instruments, etc., can solve the problems of low detection efficiency, inability to detect thread pitch, and narrow application range, etc., to improve detection efficiency, Reduced equipment investment and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

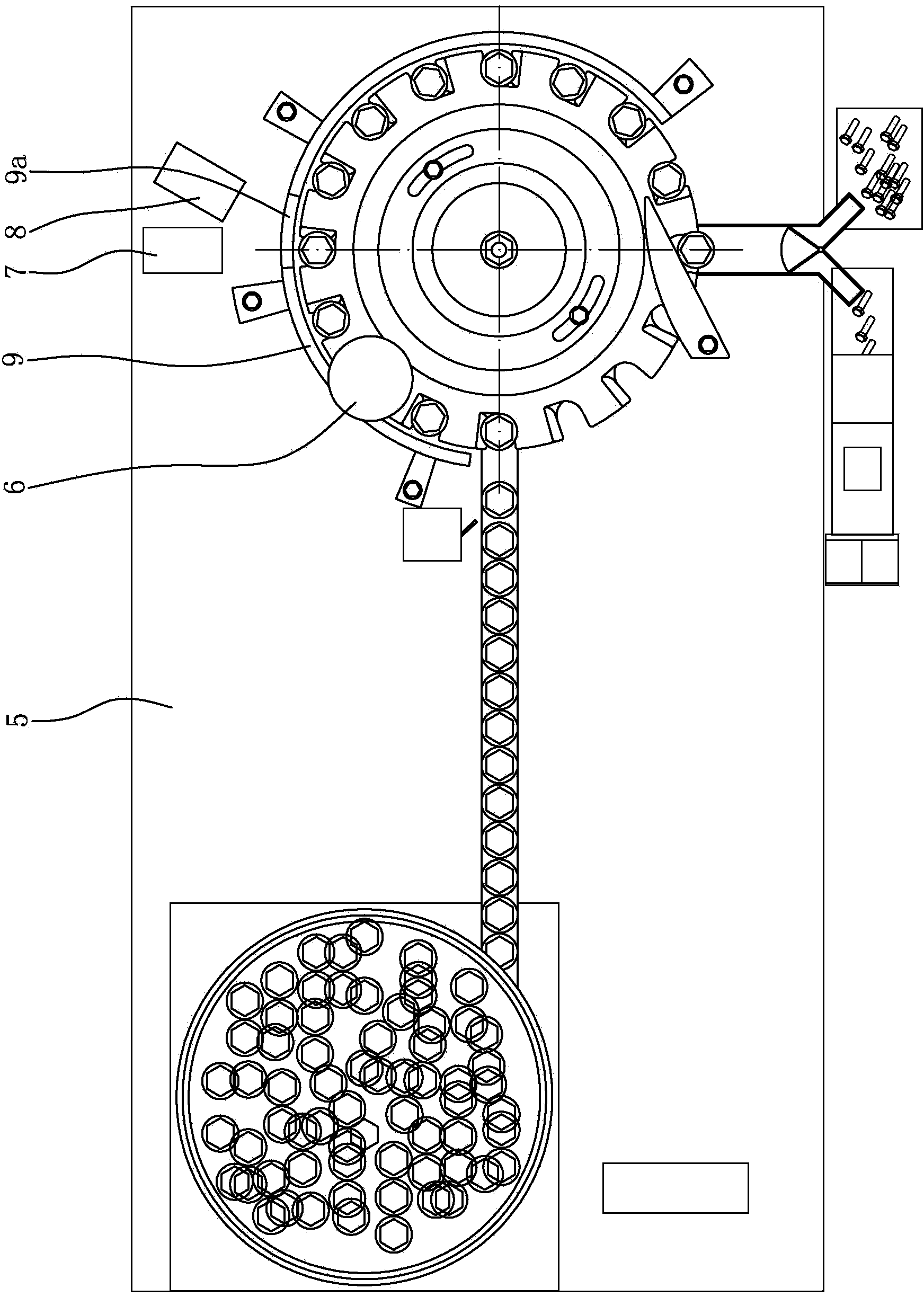

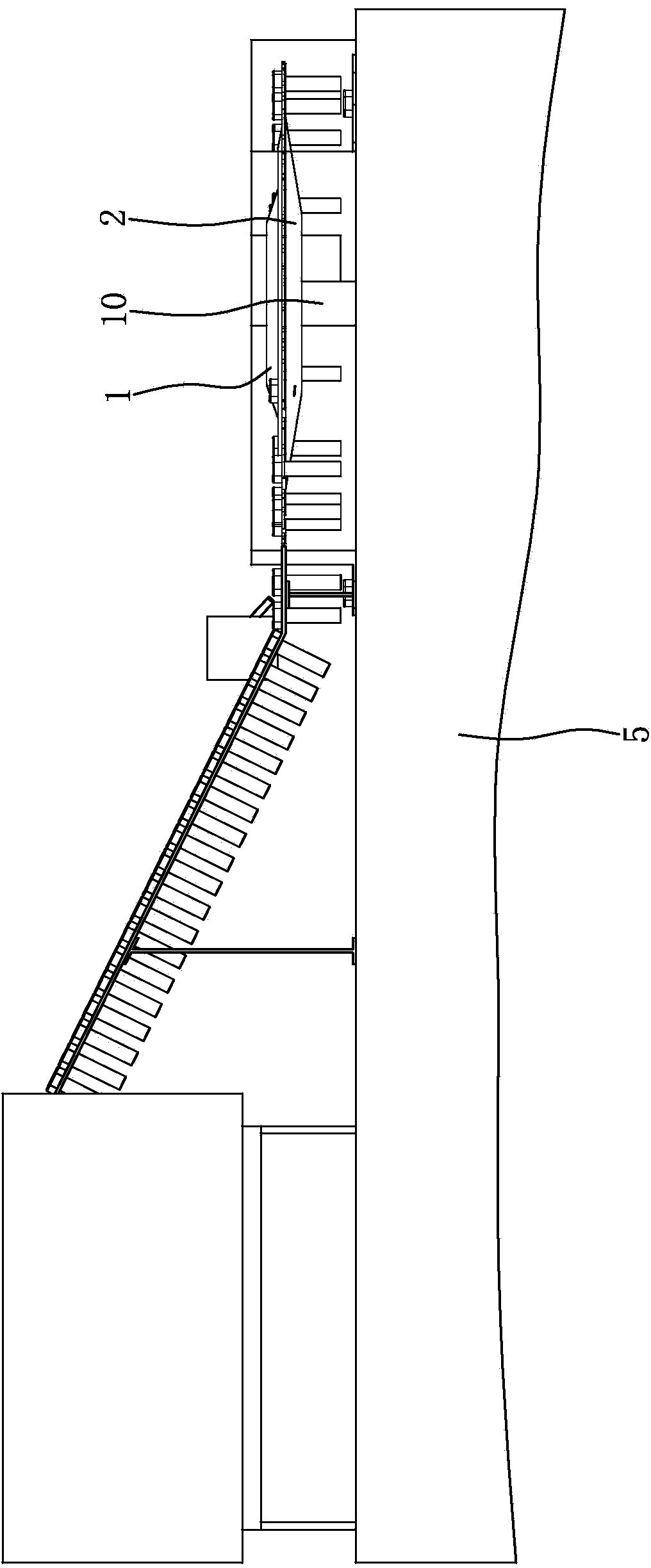

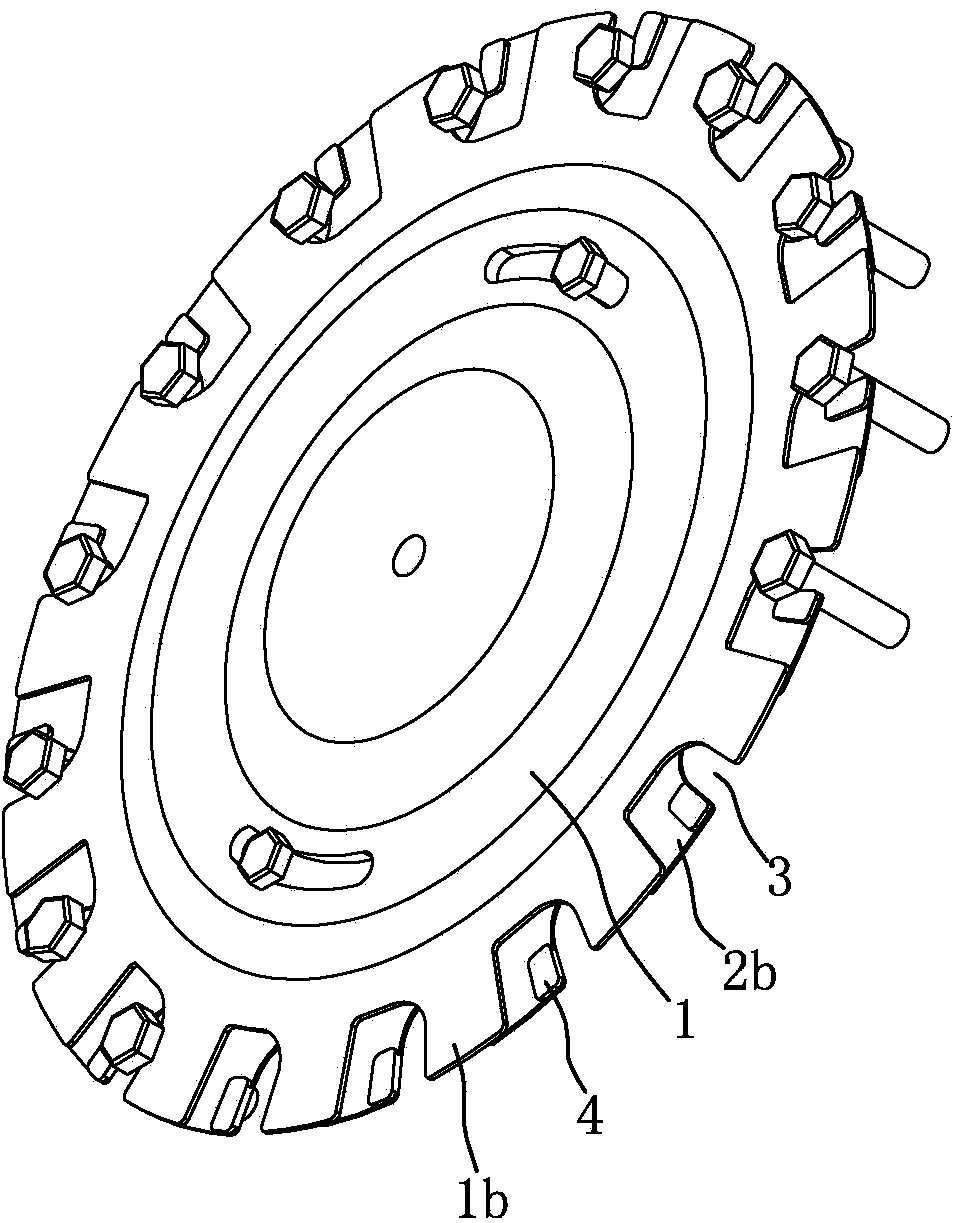

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, the indexing turntable is arranged on the machine platform 5 and consists of a moving plate 1 and a fixed plate 2 . The moving plate 1 and the fixed plate 2 are disc structures with equal diameters, and the moving plate 1 is located directly above the fixed plate 2 . The middle part of the top surface of the moving disk 1 is integrally formed with a stepped boss with a small upper part and a larger lower part; The surfaces are fitted together, and the moving plate 1 and the fixed plate 2 are connected by two fastening bolts evenly distributed on the circumference. The hole on the moving plate 1 for the fastening bolts to pass through is an arc-shaped hole 1c, and the hole 1c The center of circle is on the axis line of moving disk 1. A stepper motor 10 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com