Method for detecting shear strength of clayey soil through large on-site direct shear test device

A technology of shear strength and test device, which is applied in the direction of using a stable shear force to test the strength of materials, etc., can solve the problems of not comprehensively reflecting the true strength of cohesive soil, limited applicable occasions, and inability to detect samples. Stable force application, improved safety and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

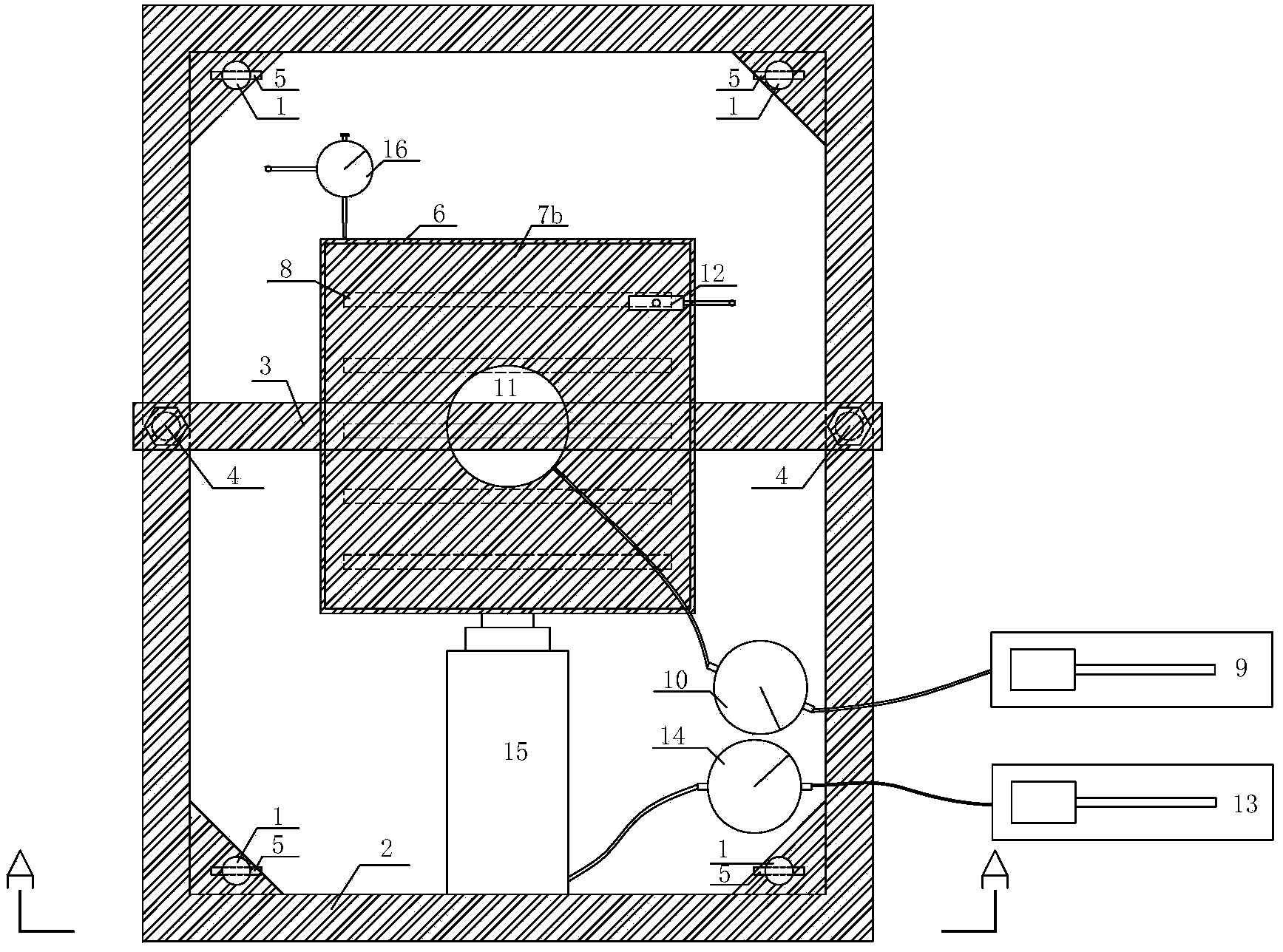

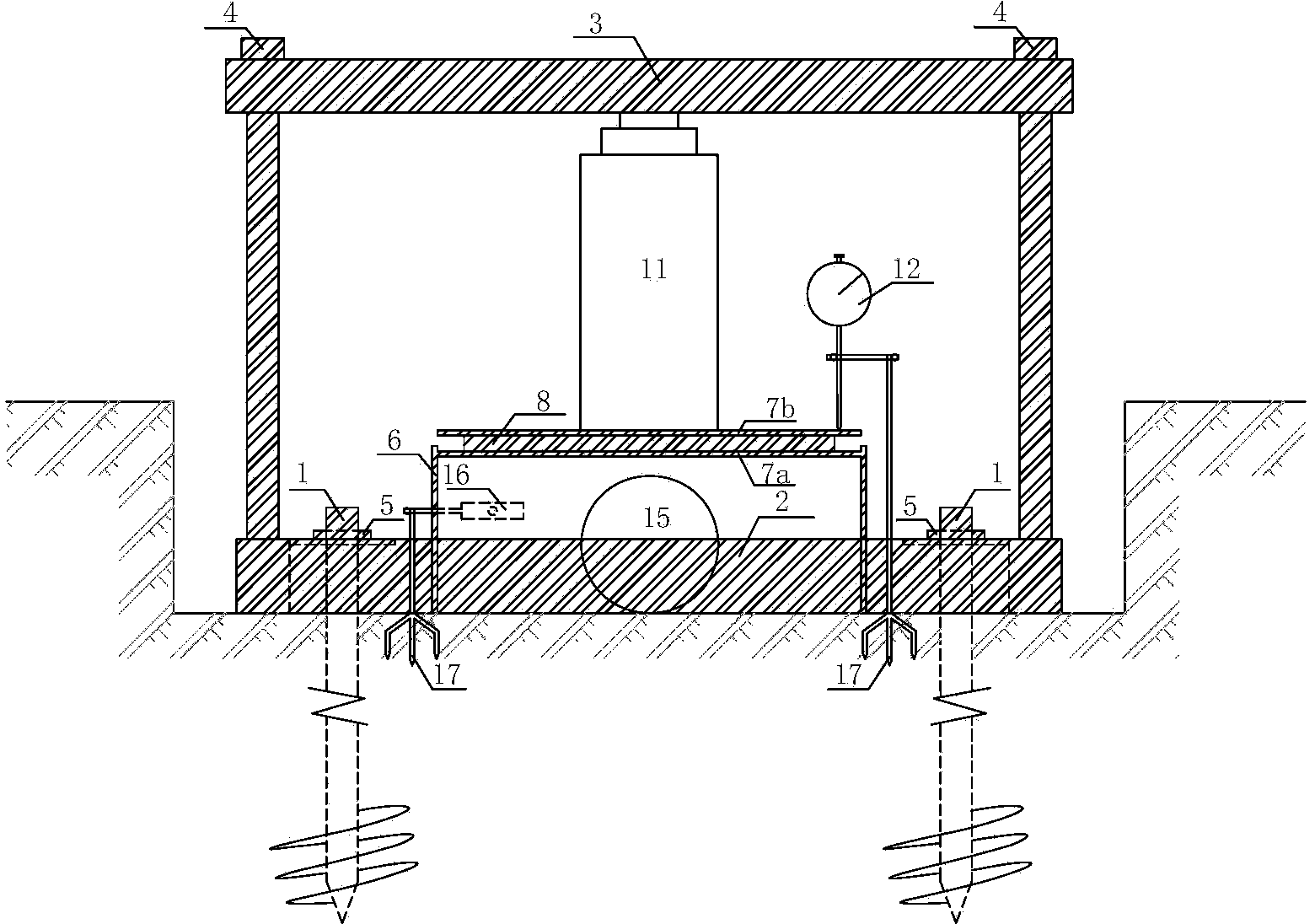

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

[0022] see Figure 1 to Figure 2 , the present invention utilizes the method for detecting the shear strength of cohesive soil by a large-scale direct shear test device on site, and involves ground anchor 1, load-bearing frame seat 2, transverse force beam 3, bolt 4, stud 5, sample box 6, lower plate 7a, upper plate 7b, roller 8, vertical hydraulic pump 9, vertical pressure gauge 10, vertical force measuring jack 11, vertical displacement indicator 12, lateral hydraulic pump 13, lateral pressure gauge 14, lateral Force measuring jack 15, lateral displacement indicating table 16 and fixed support 17.

[0023] The sample box 6 is used to place the cohesive soil sample to control the force of the sample. The length, width and height of the sample box 6 are respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com