Test device for measurement of partial discharge signal attenuation by ultrasonic method

A technology of discharge signal and ultrasonic method, which is applied in measuring devices, circuit breaker testing, measuring ultrasonic/sonic/infrasonic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

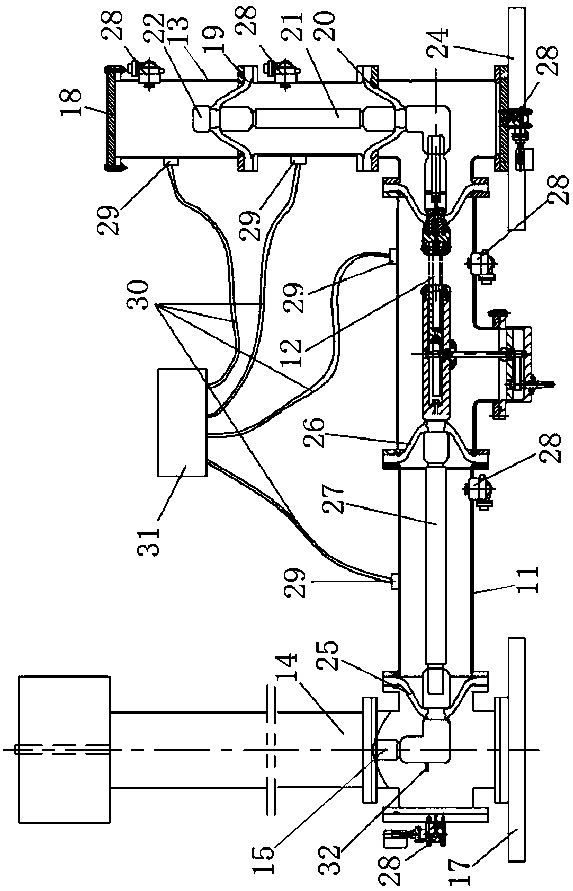

[0013] Example of a test setup for measurement of partial discharge signal attenuation by ultrasonic method, such as figure 1 As shown, the test device includes a high-voltage lead terminal, a horizontal bus sleeve 11, a disconnector 12 and a vertical bus sleeve 13, and the high-voltage lead terminal includes an external terminal sleeve 14 and a high-voltage lead 15 located in the terminal sleeve 14, The terminal sleeve 14 of the high-voltage lead terminal is arranged vertically and is fixedly equipped with a first busbar adapter barrel at the lower end. The lower end of the first busbar adapter barrel is fixedly connected with a first support seat 17. The upper end of the vertical busbar sleeve 13 An end cover 18 is closed, and an upper insulator 19 and a lower insulator 20 are arranged at intervals between the upper and lower insulators. A vertical high-voltage conductor 21 is arranged between the upper and lower insulators, and a shielding head 22 is arranged at the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com