alveolar aeration challenge

A cogging and notch technology, applied in the field of cogging-type aeration pick-up sills, can solve the problems of endangering the safe operation of drainage structures, the complex shape of differential aeration sills, and the influence of aeration facilities reliability, etc., to achieve Low cost, convenient construction, and smooth flow surface on the sill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

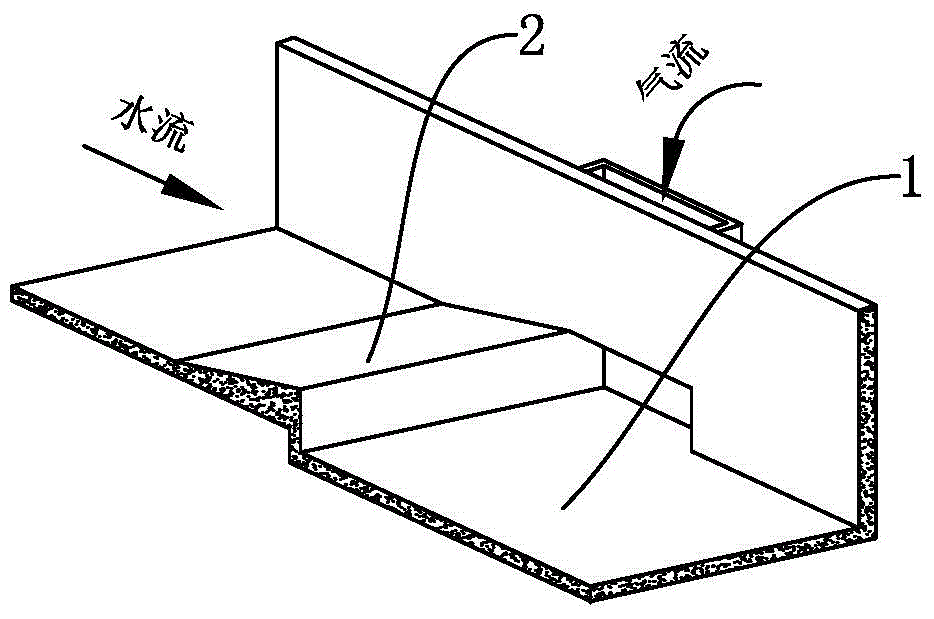

[0038] Embodiment 1: as Figure 5 As shown, the present embodiment is an alveolar-type aerated ridge, and the ridge body 2 is arranged on the floor 1 of the drainage structure, and a notch is set at the end of the ridge body 2 along the water flow direction, thereby forming a tooth ridge 201 And groove ridge 202, wherein the tooth ridge height h1>groove ridge height h2>0. The alveolar-type aerated ridge makes the water jet out from different heights after leaving the ridge, the aerated bottom surface is a concave-convex curved surface, and the area of the water-air contact surface of the cavity increases (see Figure 24 ), at the same time, the turbulence of the water flow is intensified, thereby entraining more air and increasing the aeration concentration at the bottom of the water flow. In this embodiment, the angle between the downstream surface 2021 of the ridge 202 and the bottom plate 1 of the drainage structure is an obtuse angle.

[0039] The effectiveness of this...

Embodiment 2

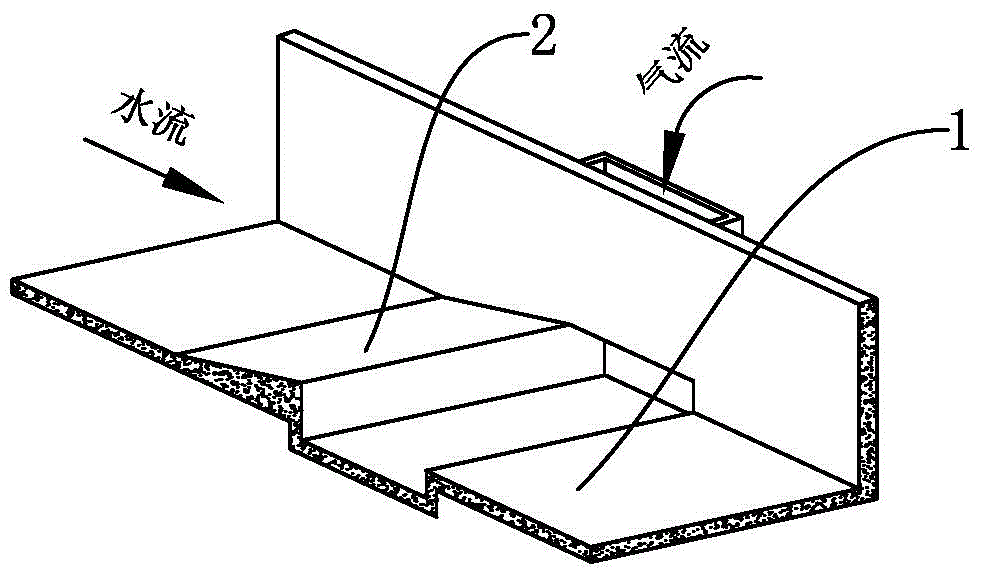

[0048] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, except that the downstream surface 2021 of the ridge 202 used in this embodiment is perpendicular to the bottom plate 1 of the drainage structure (see Figure 15 - Figure 18 ).

Embodiment 3

[0049]Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 2, the only difference is that this embodiment adopts a type in which the widths of the teeth and grooves change along the direction of water flow. Such as Figure 19 As shown in -22, the width of the tooth ridge 201 decreases gradually along the water flow direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com