Elastic rail type automatic pipeline outer wall welding mechanism

A technology for elastic rails and outer walls of pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor overall forming quality, high physical strength and technical requirements of welders, oil and natural gas leakage, etc. Problems, to achieve the effect of light weight, easy operation, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

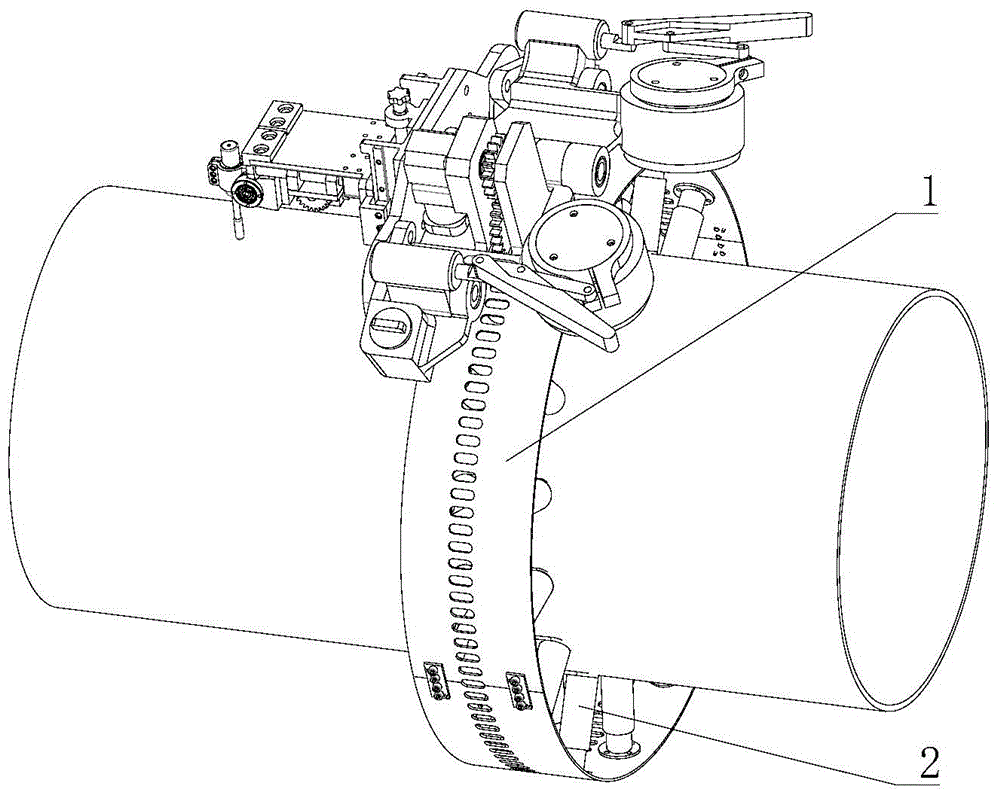

[0021] figure 1 Among them, the elastic track-type pipeline outer wall automatic welding mechanism and the elastic track mechanism 1 are assembled to form an all-position pipeline welding robot, which is applied to the outer wall welding of circular straight pipelines. The elastic track type pipe outer wall automatic welding mechanism mainly has four control degrees of freedom in the work, which are 3600 degrees of freedom to rotate along the circular track, the radial movement mechanism to move the degree of freedom along the diameter of the pipe, and the axial movement mechanism to move along the parallel The degree of freedom of reciprocating movement in the axial direction of the pipe, and the degree of freedom of the circular reciprocating swing of the welding torch.

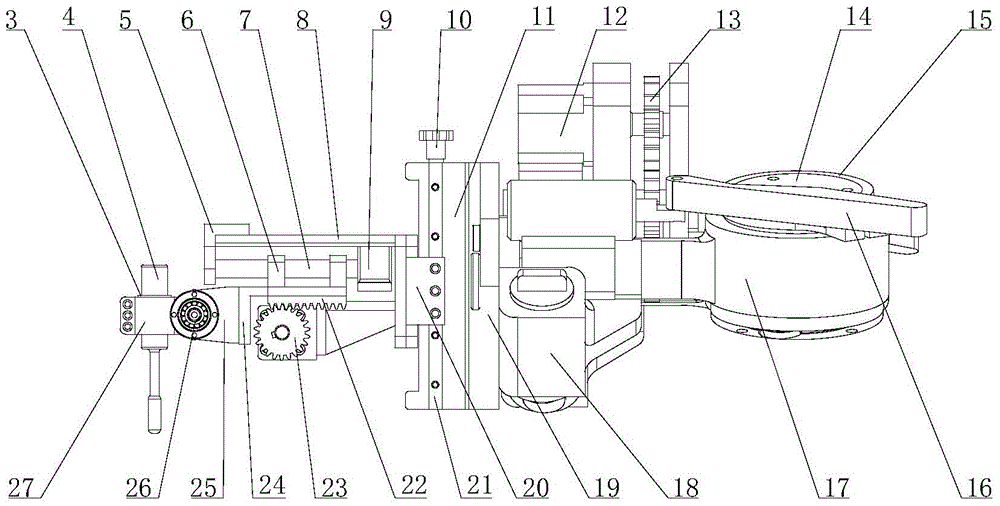

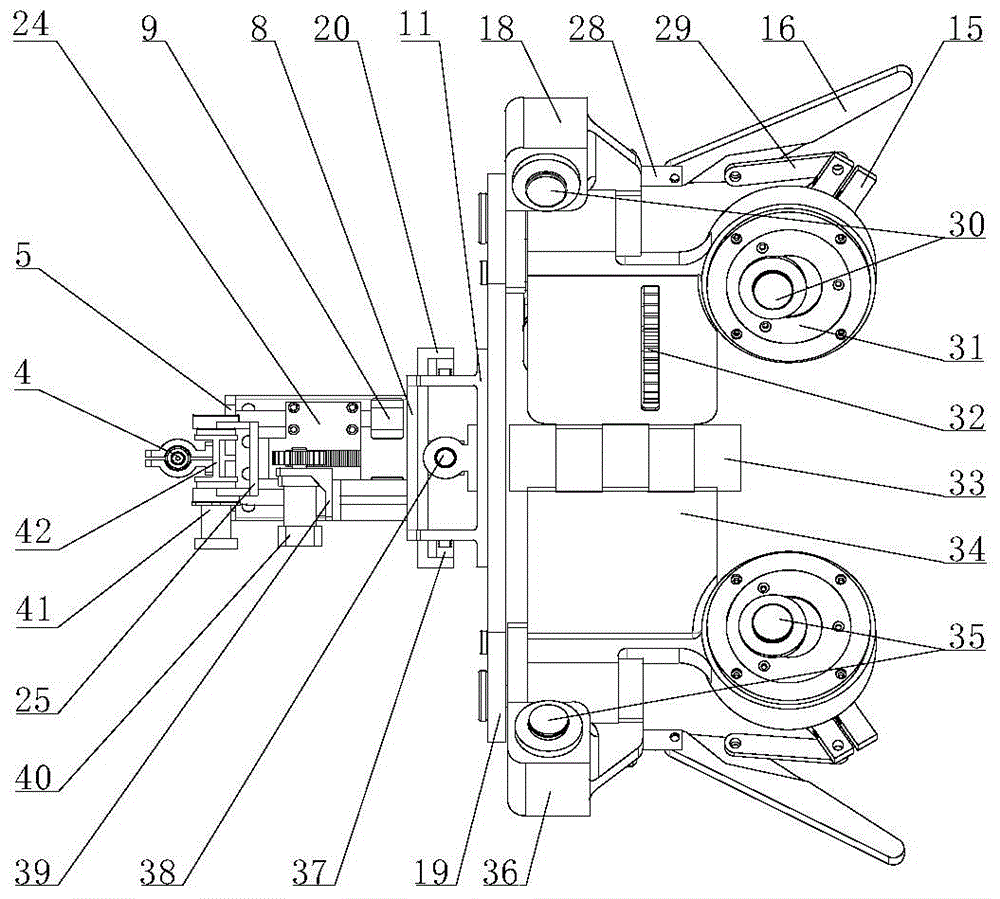

[0022] combine Figure 2-5 , the present invention includes a circumferential drive motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com