Production line for V-method modeling

A production line and modeling technology, applied in casting and molding equipment, manufacturing tools, casting workshops, etc., can solve the problems of low production efficiency workshop area utilization, high labor costs, and many safety hazards, saving workshop area, The effect of saving operating time and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

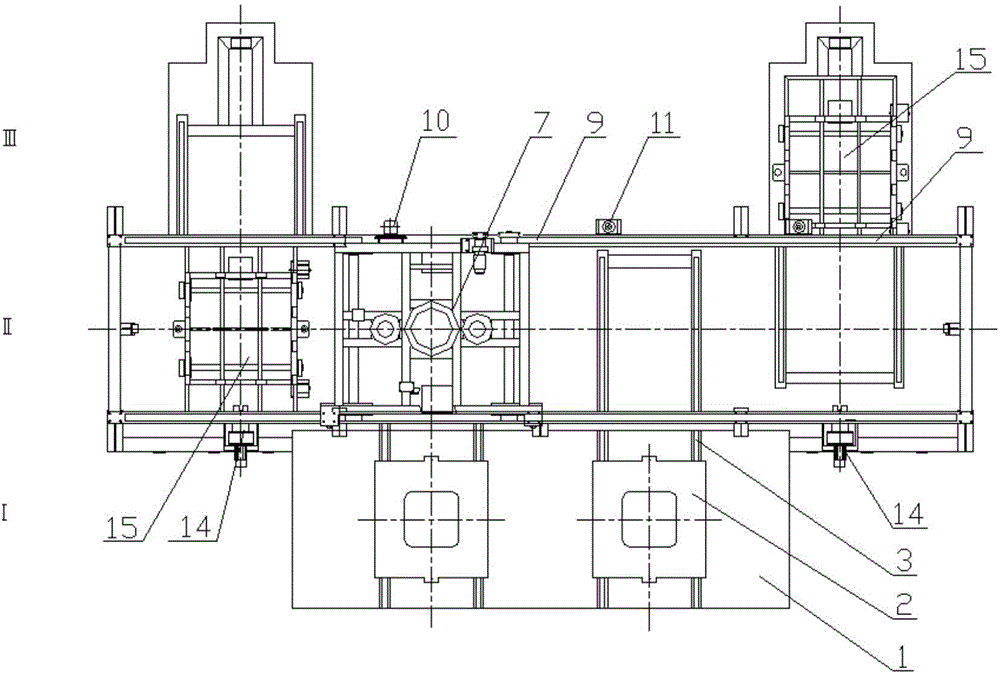

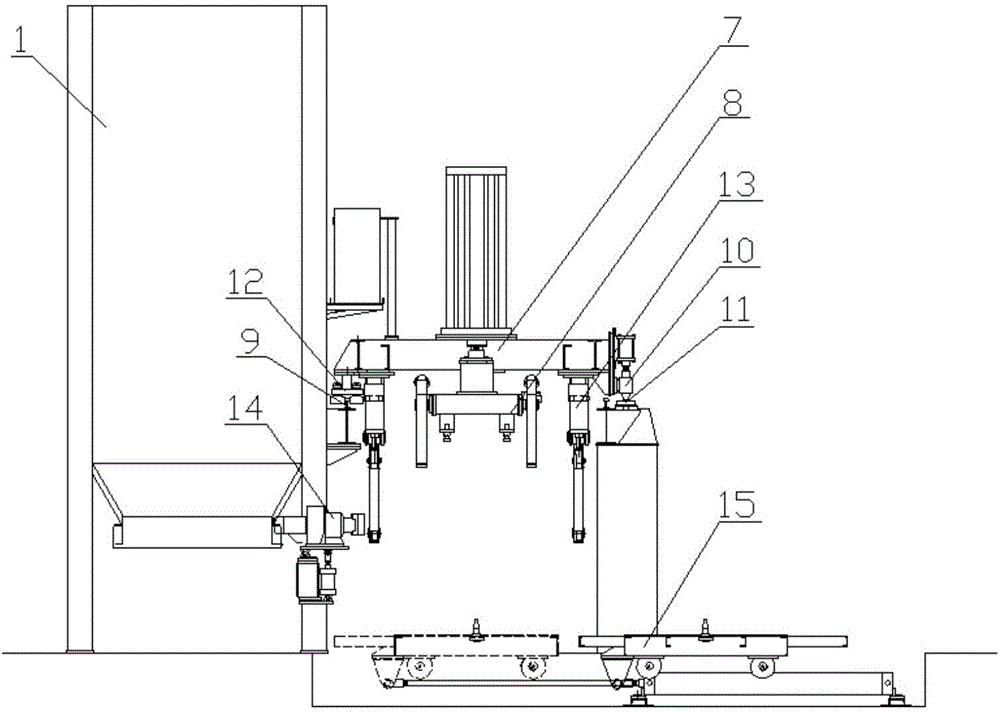

[0019] The production line for V-method molding of the present invention includes molding area I, box turning and closing area II, and core lowering area III arranged in sequence. In the molding area Ⅰ, the molding trolley 2 is responsible for making the upper and lower molds, and then transports the molds to the turning and closing area Ⅱ through the molding trolley track 3. During the operation, the positioning pin 4 of the molding trolley and the positioning pin hole of the molding trolley are used. 5. The molding trolley clamps the rollers 6 to ensure the trolley runs smoothly and positions accurately; in the box-turning and closing area II, the manipulator 8 set on the manipulator trolley 7 is responsible for demoulding and closing the molds. The box bracket 13 and the box turning machine 14 are responsible for the box turning work of the lower mold, and the manipulator trolley 7 moves the mold to each station. Precise positioning, the manipulator 8 descends to grab the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com