Automatic liquid-stopping dripping funnel

A dripping funnel and stop liquid technology, applied in the field of medical devices, can solve problems such as hidden quality problems, buoy blockage, quality problems, etc., and achieve the effects of avoiding liquid medicine waste, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

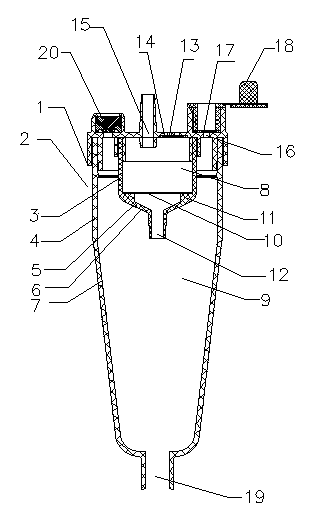

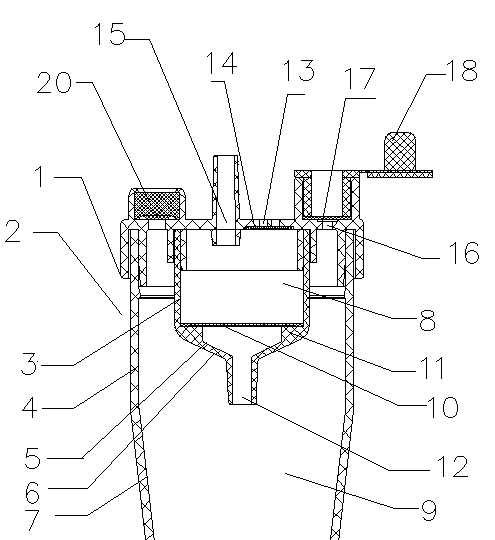

[0014] Such as figure 1 with figure 2 As shown, a kind of automatic liquid-stop dripping funnel comprises dripping funnel cover 1 and dripping funnel body 2, and dripping funnel cover 1 is arranged on the top of dripping funnel body 2, and described dripping funnel body 2 is made up of inner dripping funnel 3, outer dripping funnel 4 components, the inner wall 5 of the inner dripping funnel is combined with the dripping funnel cover 1 to form the inner dripping funnel chamber 8, the top of the inner dripping funnel chamber 8 is equipped with a vent hole 13, and the dripping funnel cover 1 on the upper part of the inner dripping funnel chamber 8 is provided with a dripping funnel The liquid inlet pipe 15, the upper part of the inner dripping funnel liquid outlet 12 at the bottom of the inner dripping funnel 3 is provided with a liquid stop filter membrane 10; the outer dripping funnel inner wall 7, the dripping funnel cover 1 and the inner dripping funnel outer wall 6 are comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com