Negative-pressure-typed granary cooling system

A cooling system and negative pressure technology, applied in the field of granary equipment, can solve the problems of high cost, inability to meet the needs of ventilation process purchase and use, complex structure, etc., and achieve cooling storage cost reduction, good social and economic benefits, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

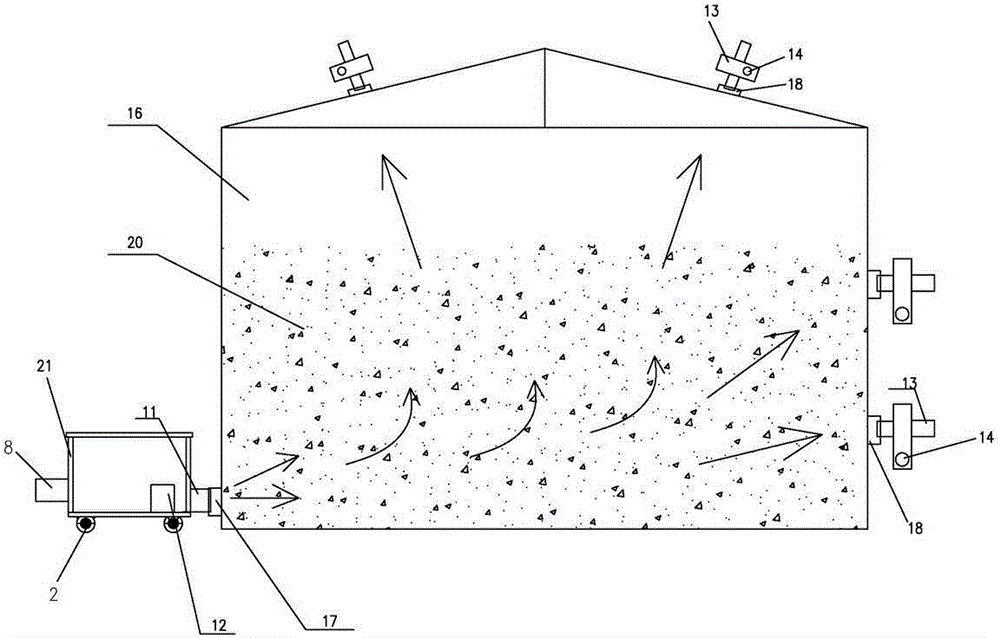

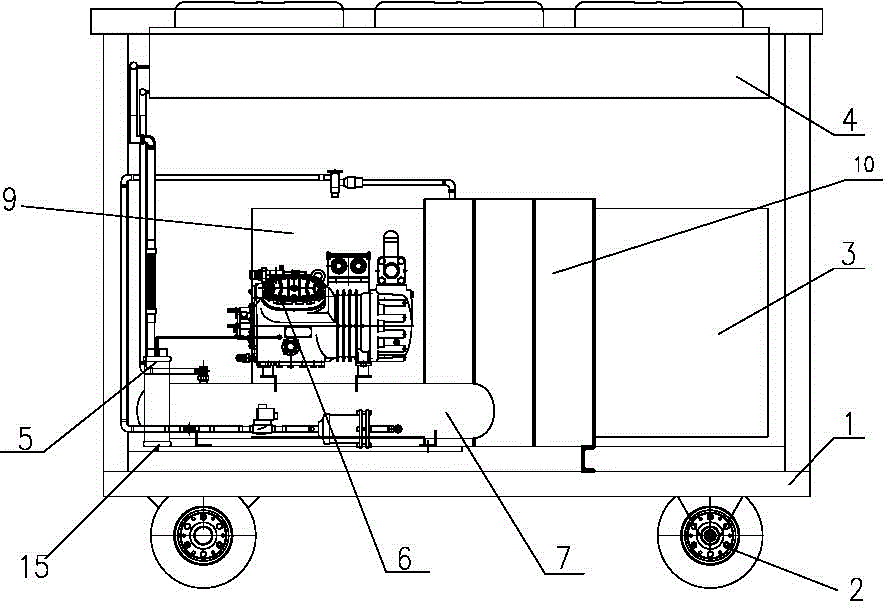

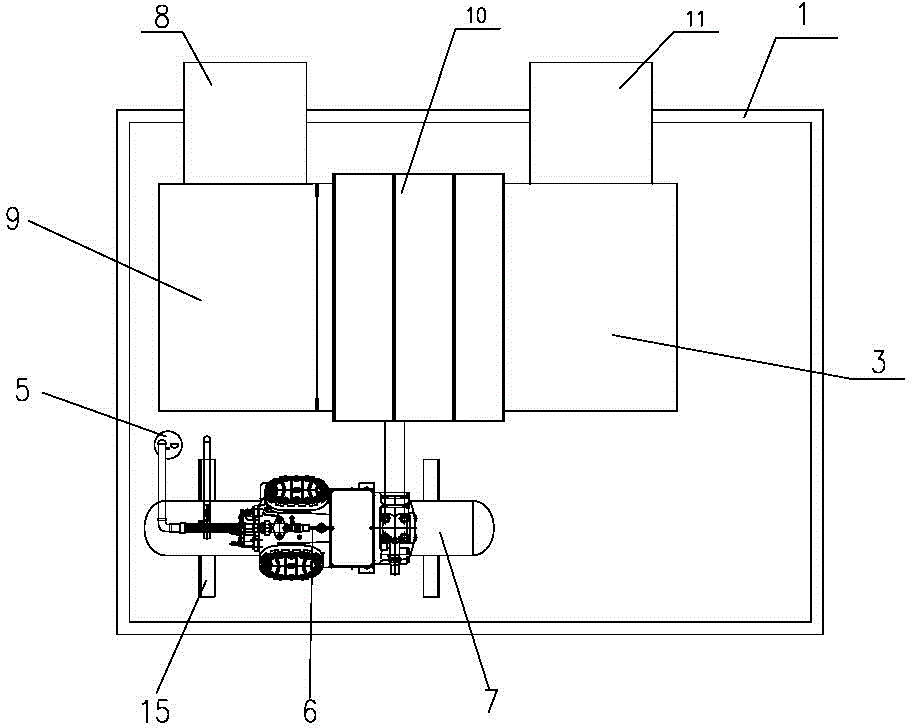

[0011] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] Depend on Figure 1-4 Provide, the present invention comprises granary, cooling machine and blower fan, there is air inlet 17 on the body of wall of granary 16 bottoms, at least one air outlet 18 is arranged on the side wall of granary 16 or the top of granary, cooler 21 is housed on the air inlet 17, and outlet The air outlet 16 is equipped with a fan 13, and the fan 13 on the air outlet 18 is forced to draw air to form a negative pressure inside the granary, and the outside air is sucked in from the air inlet 8 of the cooler 21, and the cooled air enters the inside of the granary to cool the grains installed in the granary. The stack 20 is cooled and ventilated, and finally discharged from the fan 13 on the air outlet 18, forming a negative pressure cooling structure.

[0013] In order to ensure the use effect,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com