Method for detecting subsurface damage degree characterization parameters of spherical optical element

A technique for subsurface damage, spherical optics, applied in the direction of optical devices, optical testing for flaws/defects, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

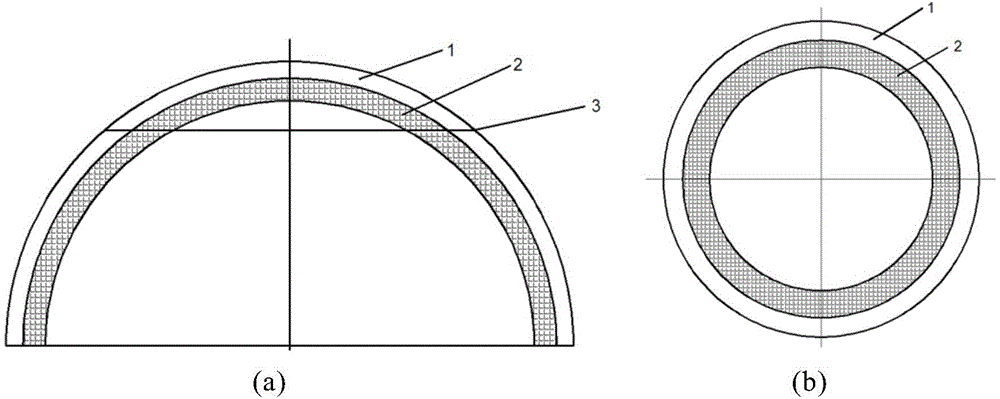

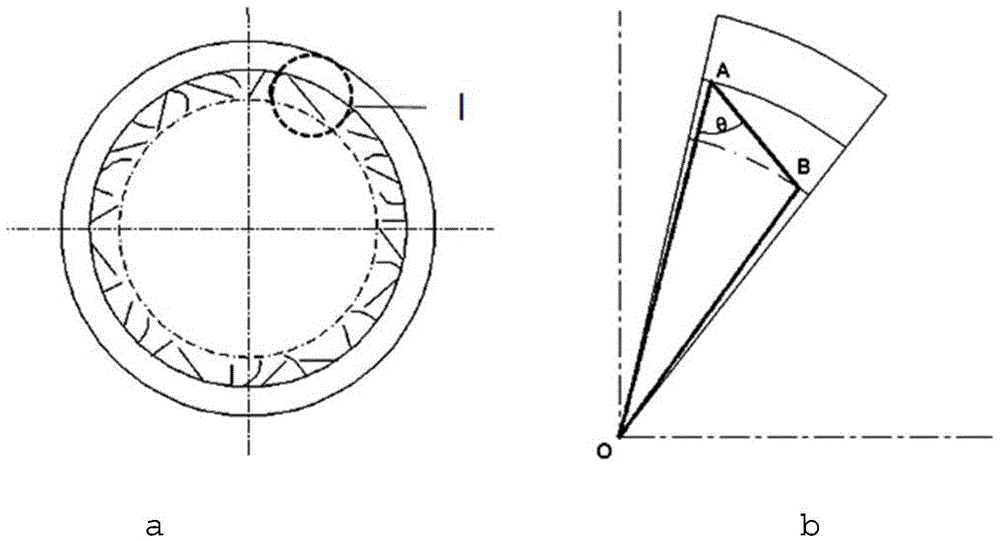

Embodiment Construction

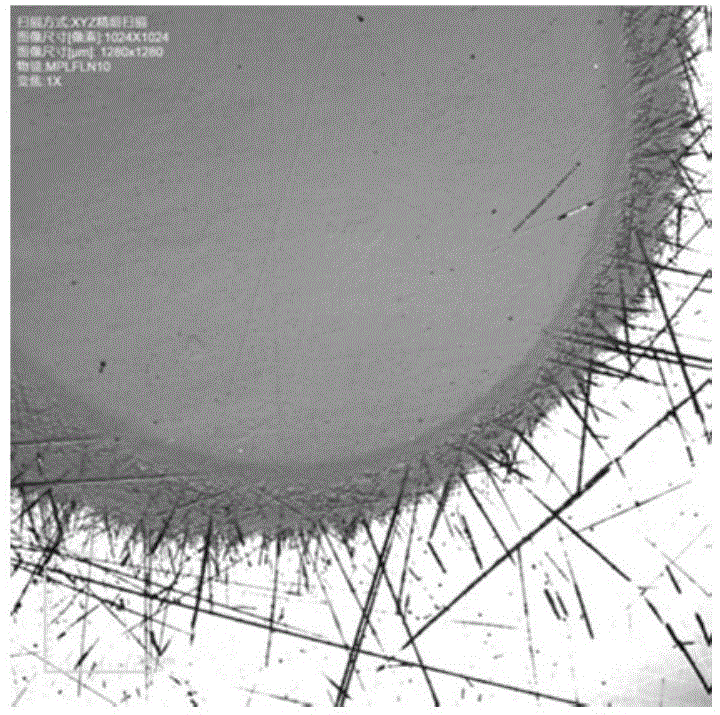

[0046] According to the polishing, corrosion and observation conditions, select a plano-convex spherical lens, the material is K9 optical glass, the diameter is 30mm, the radius of curvature is 18.041mm, the focal length is 35mm, the center thickness is 11mm, and it is coated with a 400-700nm broadband anti-reflection coating .

[0047] (1) The above-mentioned samples were polished using an annular belt magnetorheological polishing machine. The fixture of the magneto-rheological device is divided into two parts, the lens holder and the lens cover. The lens holder is made of aluminum, the lower part is M27 internal thread, and the upper part is threaded to match the lens cover. The material of the lens cover is nylon, the main purpose is to prevent the lens surface from being crushed during the process of screwing and fixing the lens. The sample was polished for 120 minutes, and the rotation speed of the polishing disc / workpiece spindle was 120 / 120r / min.

[0048] (2) Referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com