Movable electroplate hanger

A technology of electroplating hangers and fixtures, which is applied in the direction of electrolysis process and electrolysis components to achieve the effect of fast movement and convenient lateral movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A movable electroplating hanger

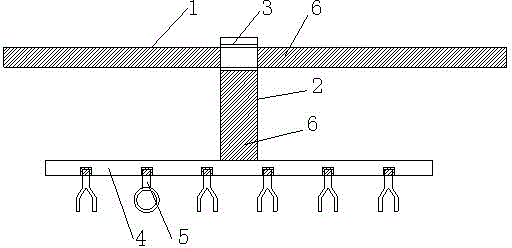

[0016] Such as figure 1 As shown, a movable electroplating hanger of the present invention includes a cross bar 1 and a fixed bar 2. The head of the fixed bar 2 is provided with a connecting hole 3 that can movably connect the fixed bar 2 and the cross bar 1. The fixed bar The bottom of 2 is connected to the hanging rod group, and the hanging rod group is composed of no less than two main rods 4 parallel to each other. The lower end of the main rod 4 is provided with a clamp 5, which is open and closed. It is formed by placing, the clamp 5 and the main rod 4 are screwed together, and the horizontal rod 1 and the fixed rod 2 are provided with an insulating sleeve 6 outside.

[0017] The horizontal bar 1 and the fixed bar 2 are movably connected together through the connecting hole 3, which facilitates the lateral movement of the fixed bar 2, and can quickly realize the movement of the hanging bar during the electroplating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com