Preparation method for phycoerythrin ACE inhibitory peptide

A technology of phycoerythrin and inhibitory peptides, which is applied in the field of preparation of phycoerythrin ACE inhibitory peptides, can solve problems such as loss of activity, and achieve the effects of reducing the amount of enzyme added, reducing costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1:

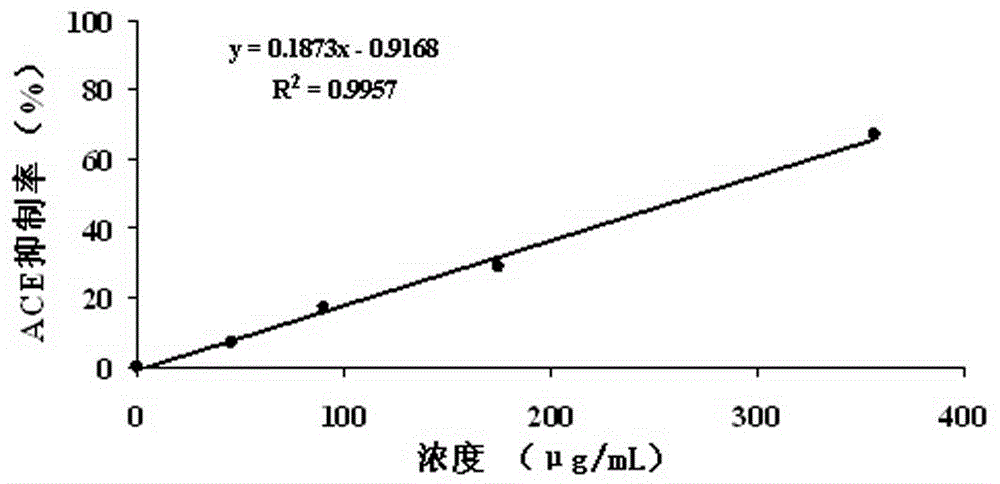

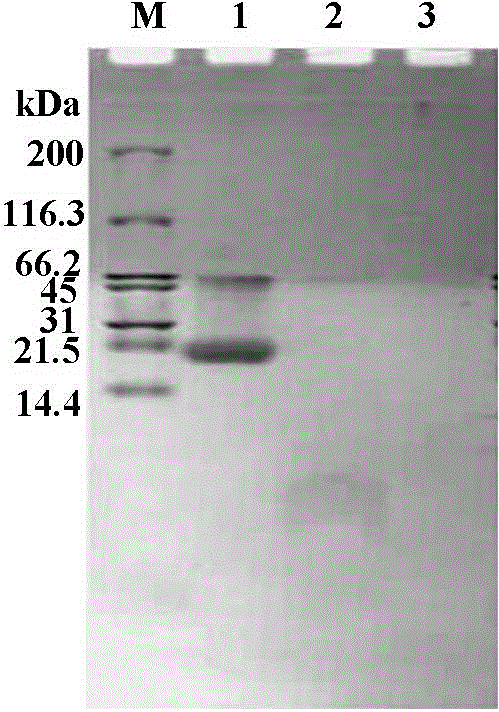

[0029] 1) Phycoerythrin extraction: 200 g of red hair algae is used as raw material, washed and dried at 40 ℃, and crushed. Add 20 times the volume of distilled water to make a seaweed suspension, freeze and thaw it repeatedly at -20 ℃ and 4 ℃ 3 times to break the cells. After 20 minutes of homogenization, the tissues were sonicated for 10 minutes. After centrifugation, the supernatant was taken and subjected to 35-50% ammonium sulfate salting out. After salting out and dialysis, load the sample on DEAE-Sepharose anion exchange column, and use 20 mmol / L PBS (pH 5.6, containing 50 mmol / L NaCl) and 20 mmol / L NaH under low light conditions 2 PO 4 The solution (containing 200 mmol / L NaCl) is mixed for linear elution. Collect A565 / A280> The eluted fraction of 3.0 was freeze-dried to make phycoerythrin powder, and stored in the dark. Prepare phycoerythrin solutions of different concentrations to determine ACE inhibitory activity. Such as figure 1 As shown, ac...

Example Embodiment

[0033] Example 2:

[0034] 1) Phycoerythrin extraction: 200 g laver is used as raw material, washed and dried at 40 ℃ and crushed. Add 30 times the volume of distilled water to make a seaweed suspension, freeze and thaw it repeatedly at -20 ℃ and 4 ℃ 5 times to break the cells. After homogenizing the tissue for 20 minutes, it was sonicated for 20 minutes. After centrifugation, the supernatant was taken and subjected to 35-50% ammonium sulfate salting out. After salting out and dialysis, load the sample on DEAE-Sepharose anion exchange column, and use 20 mmol / L PBS (pH 5.6, containing 50 mmol / L NaCl) and 20 mmol / L NaH under low light conditions 2 PO 4 The solution (containing 200 mmol / L NaCl) was mixed for linear elution at a flow rate of 1 mL / min. Collect A565 / A280> The eluted fraction of 3.0 was freeze-dried to make phycoerythrin powder, and stored in the dark. Prepare phycoerythrin solutions of different concentrations to determine ACE inhibitory activity;

[0035] 2) Enzym...

Example Embodiment

[0037] Example 3:

[0038] 1) Phycoerythrin extraction: 1 kg of red hair algae is used as raw material, washed and dried at 40 ℃ and crushed. Add 20 times the volume of distilled water to make a seaweed suspension, and freeze and thaw it repeatedly at -20 ℃ and 4 ℃ for 5 times to break the cells. After 40 minutes of homogenization, the tissues were sonicated for 30 minutes. After centrifugation, the supernatant was taken and subjected to 35-50% ammonium sulfate salting out. After salting out and dialysis, load the sample on DEAE-Sepharose anion exchange column, and use 20 mmol / L PBS (pH 5.6, containing 50 mmol / L NaCl) and 20 mmol / L NaH under low light conditions 2 PO 4 The solution (containing 200 mmol / L NaCl) was mixed for linear elution at a flow rate of 1 mL / min. Collect A565 / A280> The eluted fraction of 3.0 was freeze-dried to make phycoerythrin powder, and stored in the dark. Prepare phycoerythrin solutions of different concentrations to determine ACE inhibitory activity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com