Non-breaking corn hoister

A hoist, no crushing technology, applied in the field of conveying machinery, can solve problems such as corn crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

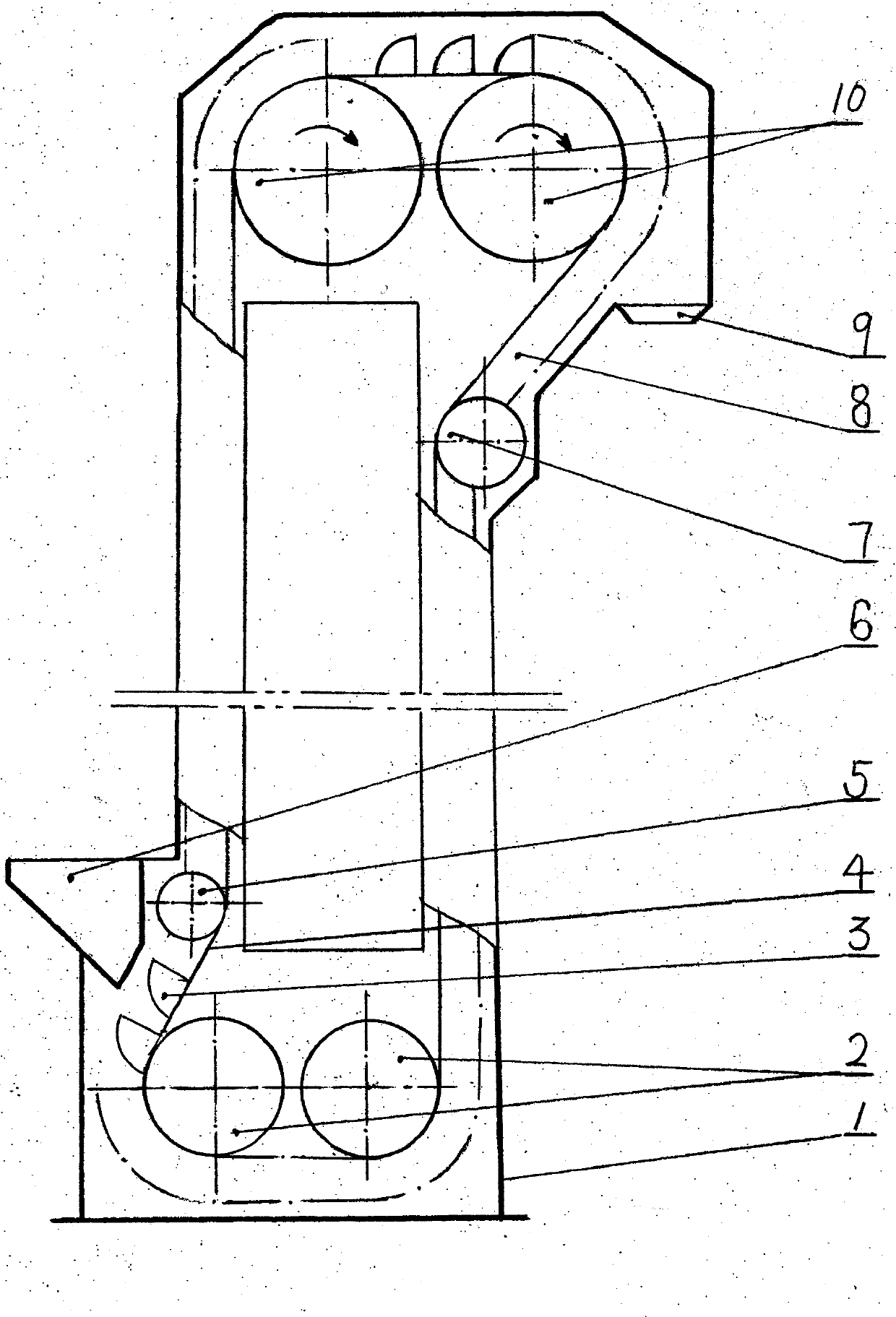

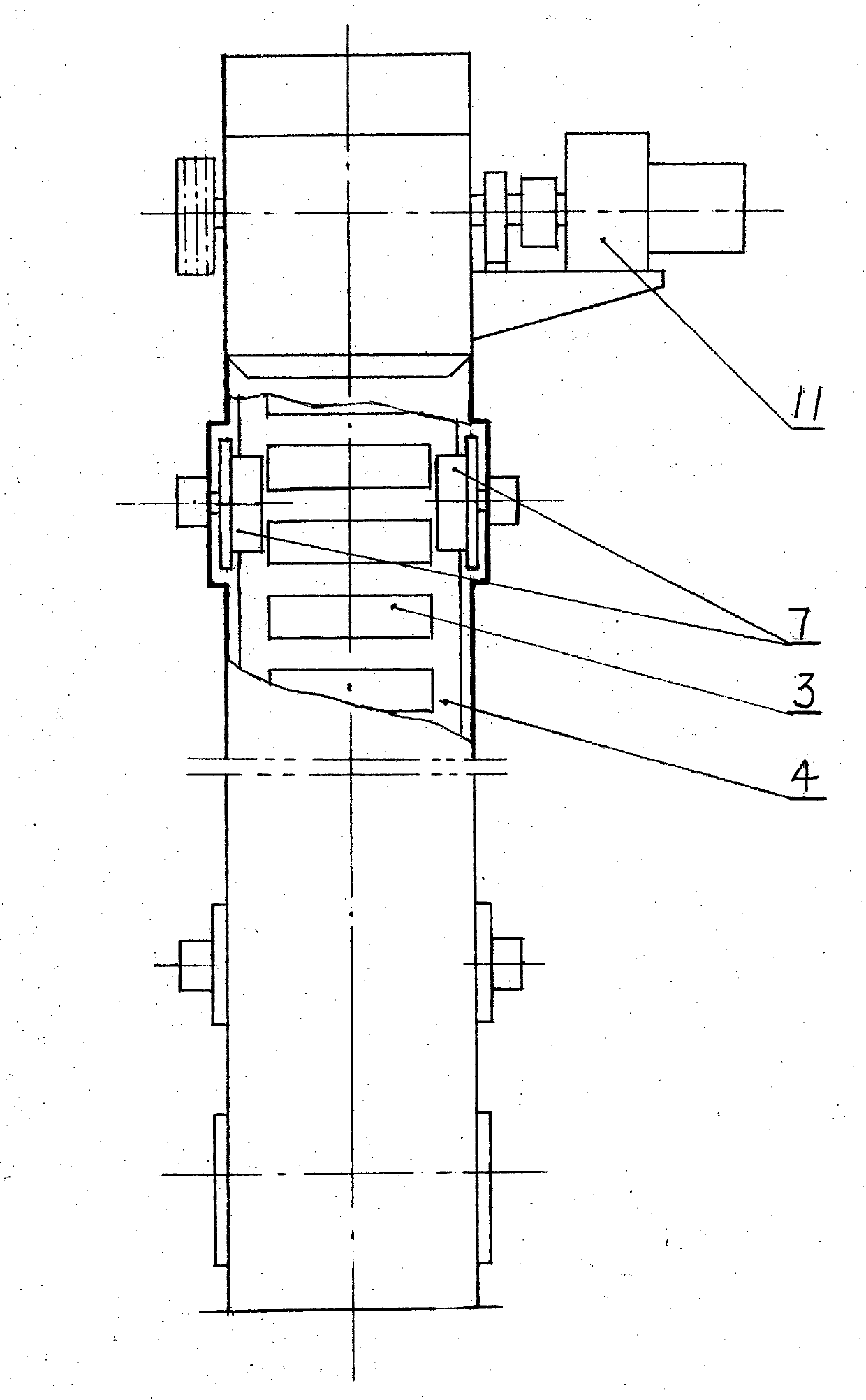

[0011] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

[0012] The feature of the present invention is: the casing (1), the feed hopper (6), the discharge hopper (9), the transmission device (11), the bottom wheel set (2), the head wheel set (10), the lower tension wheel Group (5), upper tensioning wheel group (7), bucket chain (8) form. Feed hopper (6), discharge hopper (9), transmission device (11), bottom pulley set (2), head pulley set (10), lower tension pulley set (5), upper tension pulley set (7) , bucket chain (8) are all installed on the casing (1). The bottom wheel set (2) is composed of two bottom wheels connected in series, and is installed at the bottom of the casing (1). The head wheel set (10) is composed of two head wheels in series, installed on the top of the casing (1), the front end is suspended and protruded, and the head wheel set (10) realizes synchronous rotation through belt drive conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com