An optical lens automatic dust removal device

An optical lens, automatic dust removal technology, applied in optics, optical components, chemical instruments and methods, etc., can solve the problems of high labor intensity of workers, high equipment cost, affecting imaging quality, etc., to improve market competitiveness and reduce labor intensity. , The effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

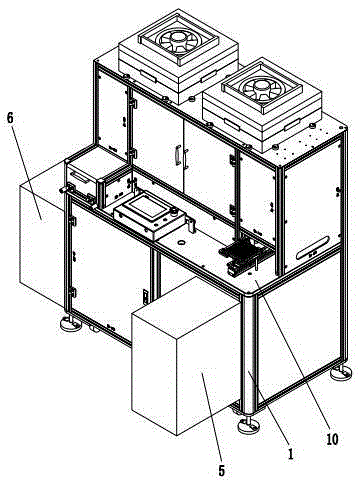

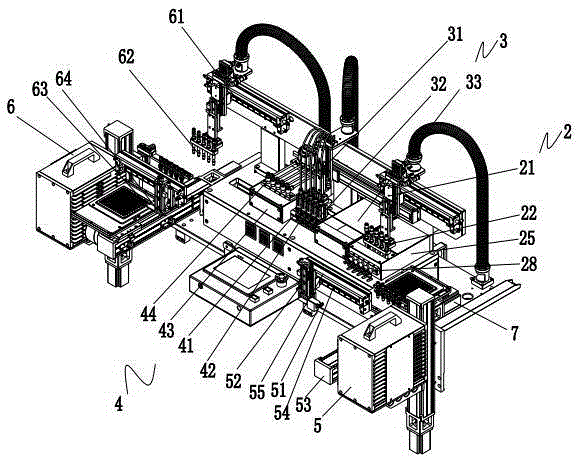

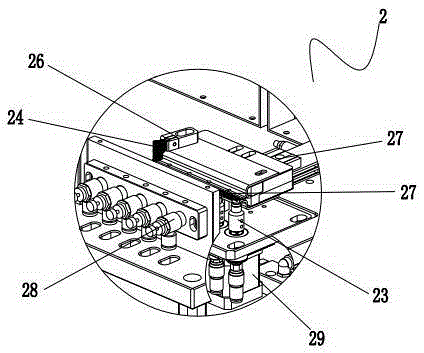

[0021] As attached Figure 1~4 As shown, an optical lens automatic dust removal equipment includes a frame 1 and a workbench 10 set on the frame 1. The workbench is sequentially provided with an outer wall cleaning mechanism 2, a reference surface cleaning mechanism 3, and a sky surface cleaning mechanism 4. The outer side wall cleaning mechanism 2 cleans the outer side wall of the optical lens, that is, the outer periphery of the optical lens, the reference surface cleaning mechanism 3 cleans the reference surface of the optical lens, that is, the bottom surface of the optical lens, and the top surface cleaning mechanism 4 cleans the top surface of the optical lens, that is, the optical lens The top surface, the outer wall cleaning mechanism 2, the reference surface cleaning mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com