Method for recovering iron concentrate from iron tailings and obtained iron concentrate

A technology for iron tailings and iron recovery, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of low recovery rate and achieve the effect of improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

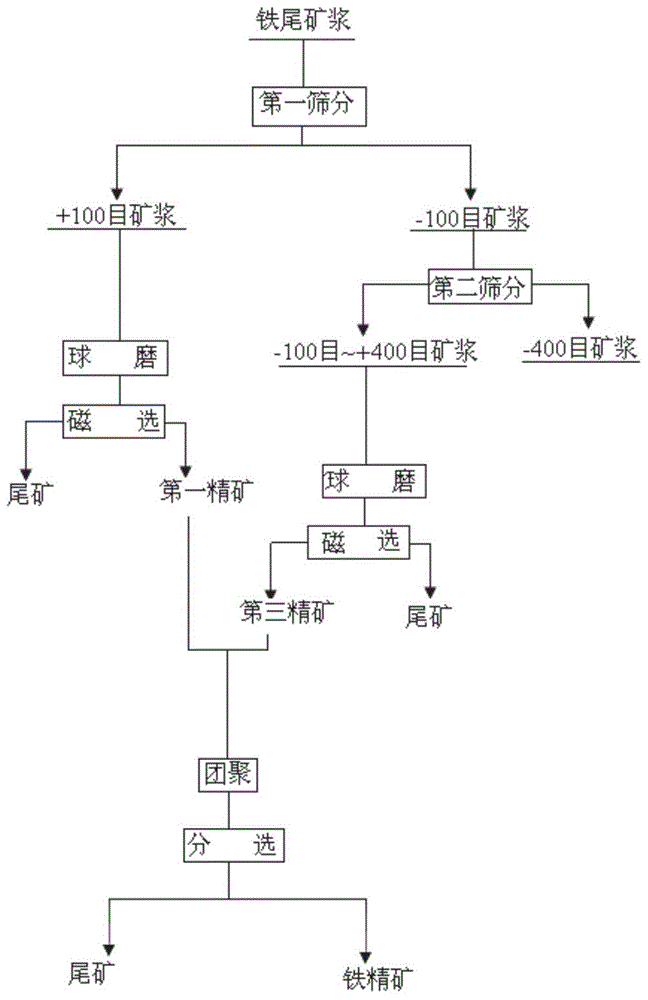

[0048] 1) The iron tailings (the total iron grade is 12%, the silica content is 70%) are first sieved through a high-frequency fine sieve to obtain the first mineral of +100 mesh and the second mineral of -100 mesh;

[0049] 2) Ball mill the first mineral until the mineral content of -400 mesh is 50%, the magnetic field strength is 15000Gs during magnetic separation, and the first concentrate with a total iron grade of 30% is obtained. For the second mineral, Φ150 and The Φ100 two-stage hydrocyclone performs the second screening to obtain the third mineral of -100~+400 mesh.

[0050] 3) Ball mill the second mineral to a mineral content of -400 mesh with a particle size of 50% and a magnetic field strength of 15000 Gs during magnetic separation to obtain a second concentrate with a total iron grade of 30%;

[0051] 4) Mix the first concentrate and the second concentrate to obtain the concentrate, add sodium bicarbonate to make the pH 10-11, and agglomerate the concentrate. The agglome...

Embodiment 2

[0055] 1) The iron tailings (the total iron grade is 17% and the silica content is 80%) are first sieved with a high-frequency fine sieve to obtain the first mineral of +100 mesh and the second mineral of -100 mesh;

[0056] 2) Ball mill the first mineral until the mineral content of -400 mesh is 60%, the magnetic field strength is 18000Gs during magnetic separation, and the first concentrate with 35% iron grade is obtained. For the second mineral, Φ150 and The Φ100 two-stage hydrocyclone performs the second screening to obtain the second mineral of -100~+400 mesh.

[0057] 3) Ball mill the second mineral to a mineral content of -400 mesh with a particle size of 60% and a magnetic field strength of 18000 Gs during magnetic separation to obtain a second concentrate with a total iron grade of 35%;

[0058] 4) Mix the first concentrate and the second concentrate to obtain the concentrate, add sodium hydroxide to make the pH 10-11, and agglomerate the concentrate. The agglomeration agent...

Embodiment 3

[0062] 1) The first sieving of iron tailings (total iron grade is 15%, silica content is 75%) is performed to obtain the first mineral of +100 mesh and the second mineral of -100 mesh. The first sieving adopts high frequency fine Sieve

[0063] 2) Ball mill the first mineral until the mineral content of -400 mesh is 60%, and the magnetic field strength is 17000Gs during magnetic separation, to obtain the first concentrate with a total iron grade of 34%. For the second mineral, Φ150 and The Φ100 two-stage hydrocyclone performs the second screening to obtain the second mineral of -100~+400 mesh.

[0064] 3) Ball mill the second mineral to a mineral content of -400 mesh with a particle size of 60% and a magnetic field strength of 17000 Gs during magnetic separation to obtain a second concentrate with a total iron grade of 34%;

[0065] 4) Mix the first concentrate and the second concentrate to obtain the concentrate. The concentrate is deslimed by a desliming machine. After desliming, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com